Method for landfill of gas fluidification dimethyl ether fuel by garbage

A technology for landfill gas and liquefaction of dimethyl ether, which is applied in the fields of isomerization to prepare ether, ether preparation, hydrogen production, etc., can solve the problems such as the dimethyl ether process that has been reported, and achieves short process flow and thermal energy utilization. The effect of high rate and simple product separation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

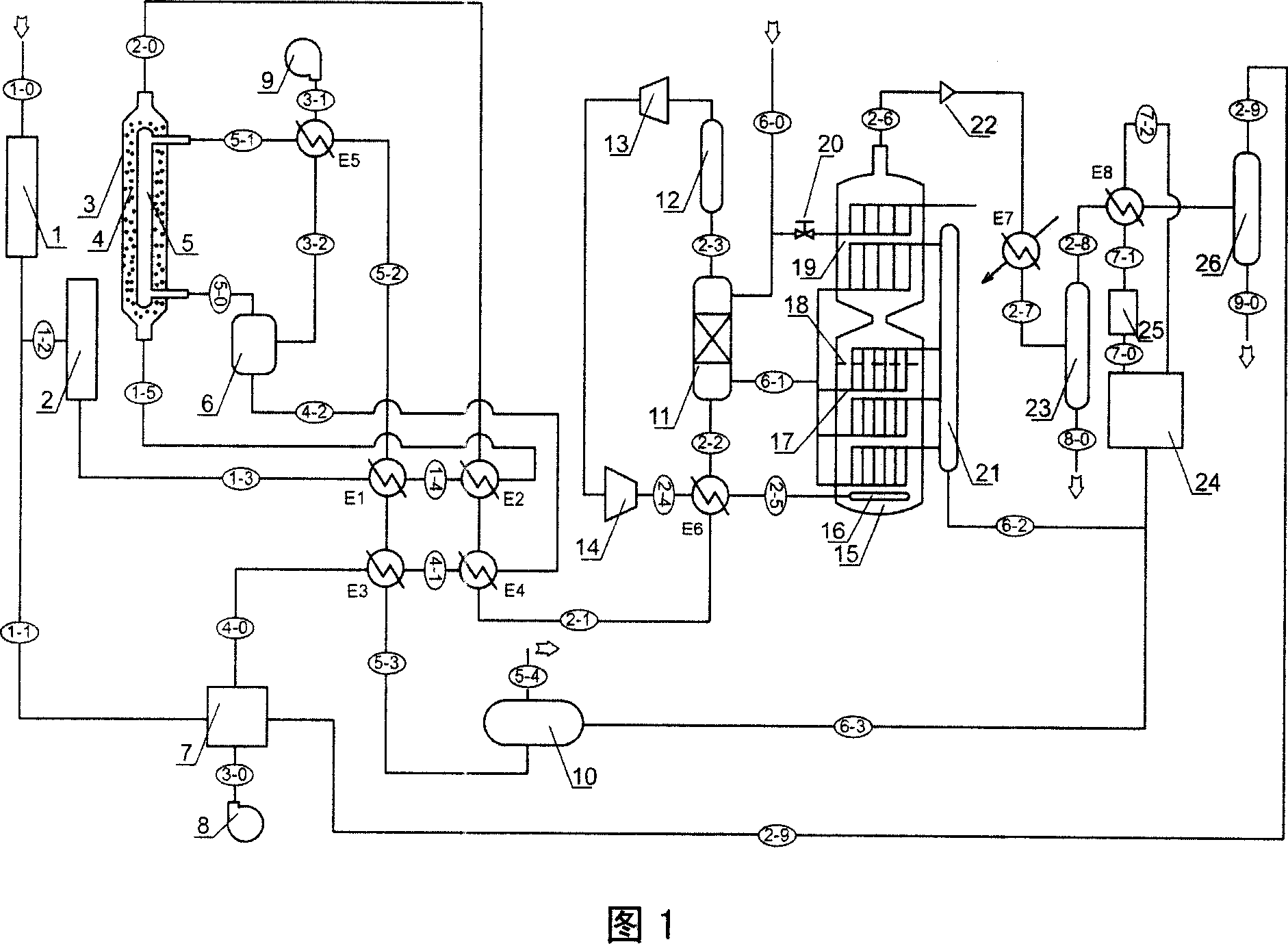

[0029] Preparation of syngas:

[0030] As shown in Figure 1, feed the preheated raw material gas into a high-temperature furnace at 700-800°C, and react through a fixed bed of catalyst at 0.1 atmospheric pressure (atm). According to the performance of the catalyst, The air velocity of raw material gas is controlled at 5000-20000h -1 . The equipment related to the reforming reaction mainly includes high-temperature furnace 3, burner 6 and heat exchanger E1-E5, and the flow rate of dilution air can be controlled by frequency conversion blower 9, thereby controlling and regulating flue gas and the temperature of reaction bed 4. Fuel gas is composed of crude desulfurized landfill gas , tail gas from the DME synthesis stage and premixed air . Mixing and preheating, the burner 6 is a porous media burner. The flue gas is a high-temperature gas after fuel combustion, which is mixed with dilution air and used as a heat source for a high-temperature furnace. Raw gas and flue g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com