Method for preparing linear polyester-imides and thermal-optical property usage thereof

A linear polyurethane and imide technology, which is applied in the field of preparation of new polyurethane-imide materials, can solve the problems of thermo-optic switch and light-switching array research that are not mentioned, and achieves high PI glass transition temperature and film formation. The effect of good performance and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

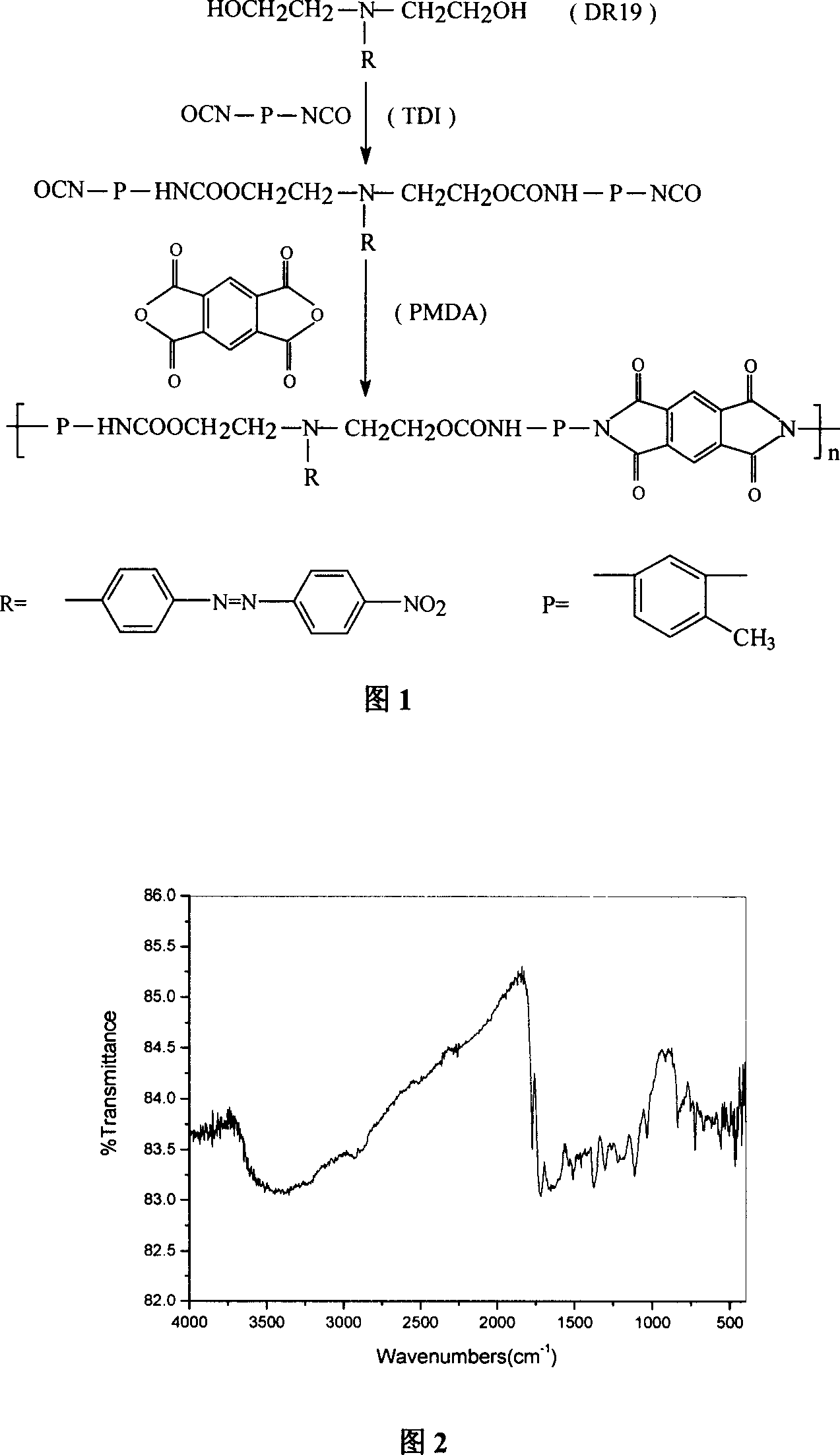

[0015] Example 1 At room temperature, add 7.2mmol TDI and 15mL DMF to a four-necked flask equipped with a reflux condenser and a nitrogen inlet, stir rapidly, and slowly add 3.0mmol DR-19 DMF solution dropwise. After the dropwise addition, raise the temperature to 90°C to react for 40 Minutes to obtain a polyurethane prepolymer terminated with -NCO. Cool in an ice bath, add 4.8 mmol of dianhydride PMDA, raise the temperature to 40°C for 4 hours, then raise the temperature to 90°C and reflux for 5 hours, the product is precipitated into methanol aqueous solution (volume ratio: 1:1), suction filtered, and vacuum dried , to obtain the red polyurethane-imide (PUI) material TIP-1 containing nonlinear optical groups in the side chain.

Embodiment 2

[0016] Example 2 At room temperature, add 7.2mmol TDI and 15mL DMF to a four-necked flask equipped with a reflux condenser and a nitrogen inlet, stir rapidly, and slowly add 4.8mmolDR-1 DMF solution dropwise. After the dropwise addition, raise the temperature to 40°C for reaction 3 hours, to obtain -NCO-terminated polyurethane prepolymer. Cool in an ice bath, add 2.4 mmol of dianhydride BPDA, heat up to 110°C for 40 minutes, then heat up to 200°C and reflux for 1 hour. The product is precipitated into aqueous methanol (volume ratio: 1:1), filtered with suction, After vacuum drying, a red polyurethane-imide (PUI) material TIP-2 containing nonlinear optical groups in the side chain was obtained.

Embodiment 3

[0017] Example 3 At room temperature, add 7.2mmol TDI and 15mL DMF to a four-necked flask equipped with a reflux condenser and a nitrogen inlet, stir rapidly, and slowly add 4.0mmol DR-19 DMF solution dropwise. After the dropwise addition, raise the temperature to 70°C to react 1.5 hours, to obtain -NCO-terminated polyurethane prepolymer. Cool in an ice bath, add 3.2 mmol of dianhydride BTDA, heat up to 90°C and react for 2 hours, then heat up to 160°C and reflux for 2.5 hours, the product is precipitated into methanol aqueous solution (1:1 by volume), and suction filtered , after vacuum drying, the red polyurethane-imide (PUI) material TIP-3 containing nonlinear optical groups in the side chain was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com