Method for producing propenyl alcohol

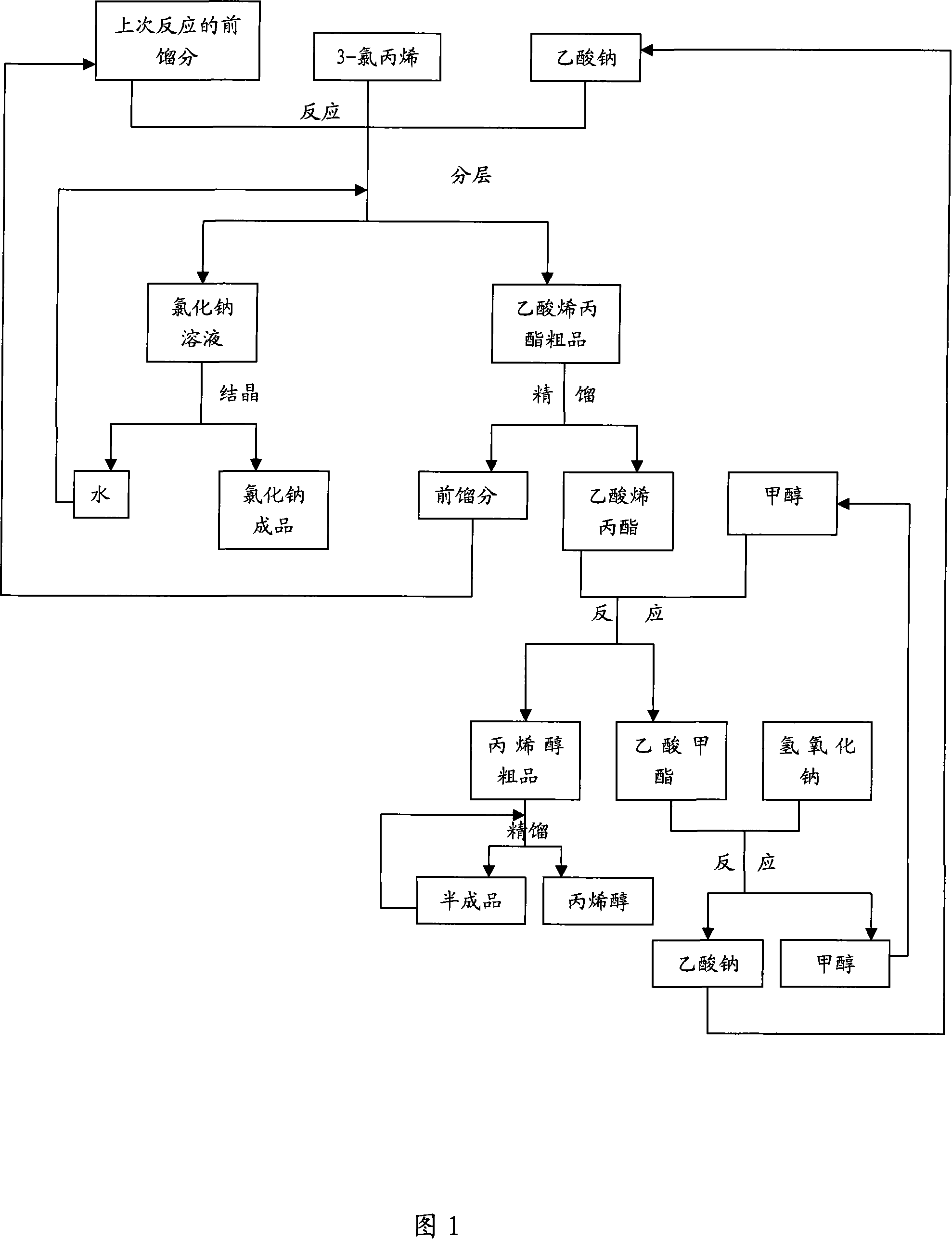

A production method, the technology of propylene alcohol, applied in alcoholysis preparation, organic chemistry, etc., can solve the problems of serious environmental pollution and difficult post-processing, and achieve the effects of high conversion rate of raw materials, easy control and operation, and reasonable technical route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

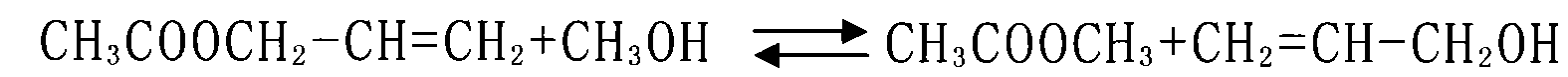

Method used

Image

Examples

Embodiment 1

[0030] 76.5kg of 3-chloropropene (100%, the same below) is pumped into the reactor, and 90.2kg of anhydrous sodium acetate (100% off, the same below) and 0.383kg of methanol (100% off, the same below) are dropped from the manhole. same), close all valves on the kettle, start stirring, slowly turn on the steam to raise the temperature from 60°C to 120°C, keep the temperature for about 5 hours, cool down and add water to static layering, press the oil phase into the rectification kettle, and rectify at atmospheric pressure to obtain allyl acetate The yield of ester was 93%, which was 93 kg. Put the rectified allyl acetate into another rectifying kettle, add 89.3kg methanol (100%, the same below) and 46.5kg epoxy resin at the same time, slowly open the steam, reflux reaction for 3 hours, first take out the reaction generated Methyl acetate, followed by recovery of unreacted methanol, and then recovery of propylene alcohol, the yield was 90%, which was 48.5 kg. Put methyl acetate...

Embodiment 2

[0032] Pump 76.5kg of 3-chloropropene into the reaction kettle, put 98.4kg of anhydrous sodium acetate and 0.765kg of methanol from the manhole, close all valves on the kettle, start stirring, slowly turn on the steam to raise the temperature to 60°C-120°C, and keep warm for about After 5 hours, the temperature was lowered, water was added and the layers were statically separated. The oil phase was pressed into a rectification kettle and rectified under normal pressure. The yield of allyl acetate obtained was 94.8%, which was 94.8kg. Put the rectified allyl acetate into another rectifying still, add 182kg methanol and 15.8kg epoxy resin at the same time, slowly turn on the steam, reflux for 3 hours, first take out the methyl acetate generated by the reaction, and then collect the unreacted Methanol, and then collect propylene alcohol, the productive rate is 89%, is 48.9kg. Put methyl acetate into another reaction kettle, put into sodium hydroxide solution, slowly heat the reac...

Embodiment 3

[0034] Pump 76.5kg of 3-chloropropene into the reaction kettle, put 90.2kg of anhydrous sodium acetate and 0.306kg of ethanol from the manhole, close all valves on the kettle, start stirring, slowly turn on the steam to raise the temperature to 60℃~120℃, and keep the heat for about After 5 hours, the temperature was lowered, water was added and the layers were statically separated. The oil phase was pressed into a rectification kettle and rectified under normal pressure. The yield of allyl acetate obtained was 76.6%, which was 76.6 kg. Put the rectified allyl acetate into another rectification kettle, add 73.5kg methanol and 38.3kg epoxy resin at the same time, slowly turn on the steam, reflux for 3 hours, first take out the methyl acetate generated by the reaction, and then collect the unreacted methanol, and then recover propenyl alcohol with a yield of 75%, which is 33.1kg. Put methyl acetate into another reaction kettle, put into sodium hydroxide solution, slowly heat the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com