Method for manufacturing variant barrier gallium nitride FET

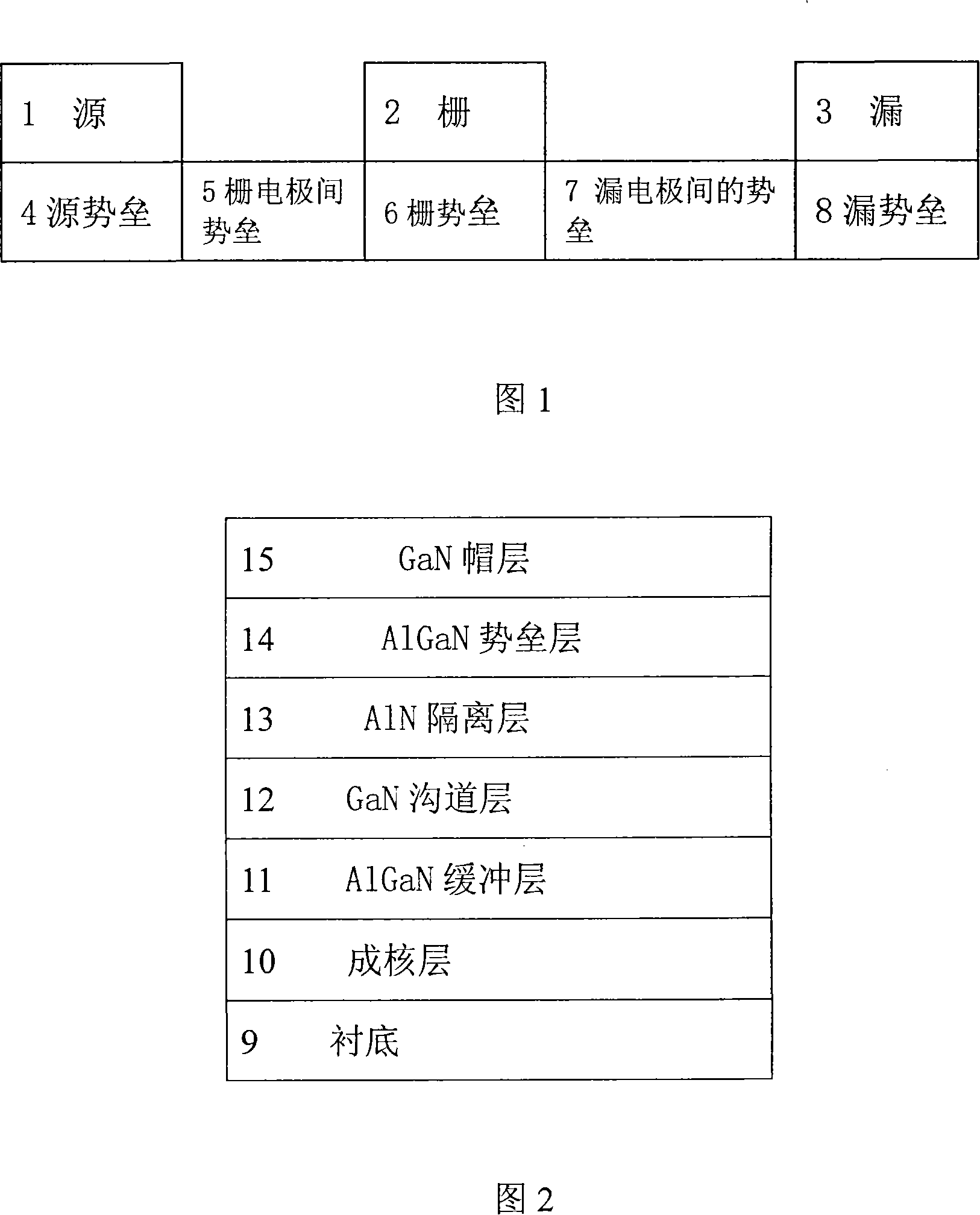

A gallium nitride field and field effect transistor technology is applied in the manufacture of semiconductor devices, the manufacture of low gate current and high reliability gallium nitride field effect transistors, and the manufacture of variable barrier gallium nitride field effect transistors, which can solve current collapse. , increasing the distance between the gate electrode and the channel, reducing the transconductance and pinch-off voltage, etc., to achieve the effect of raising the potential barrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

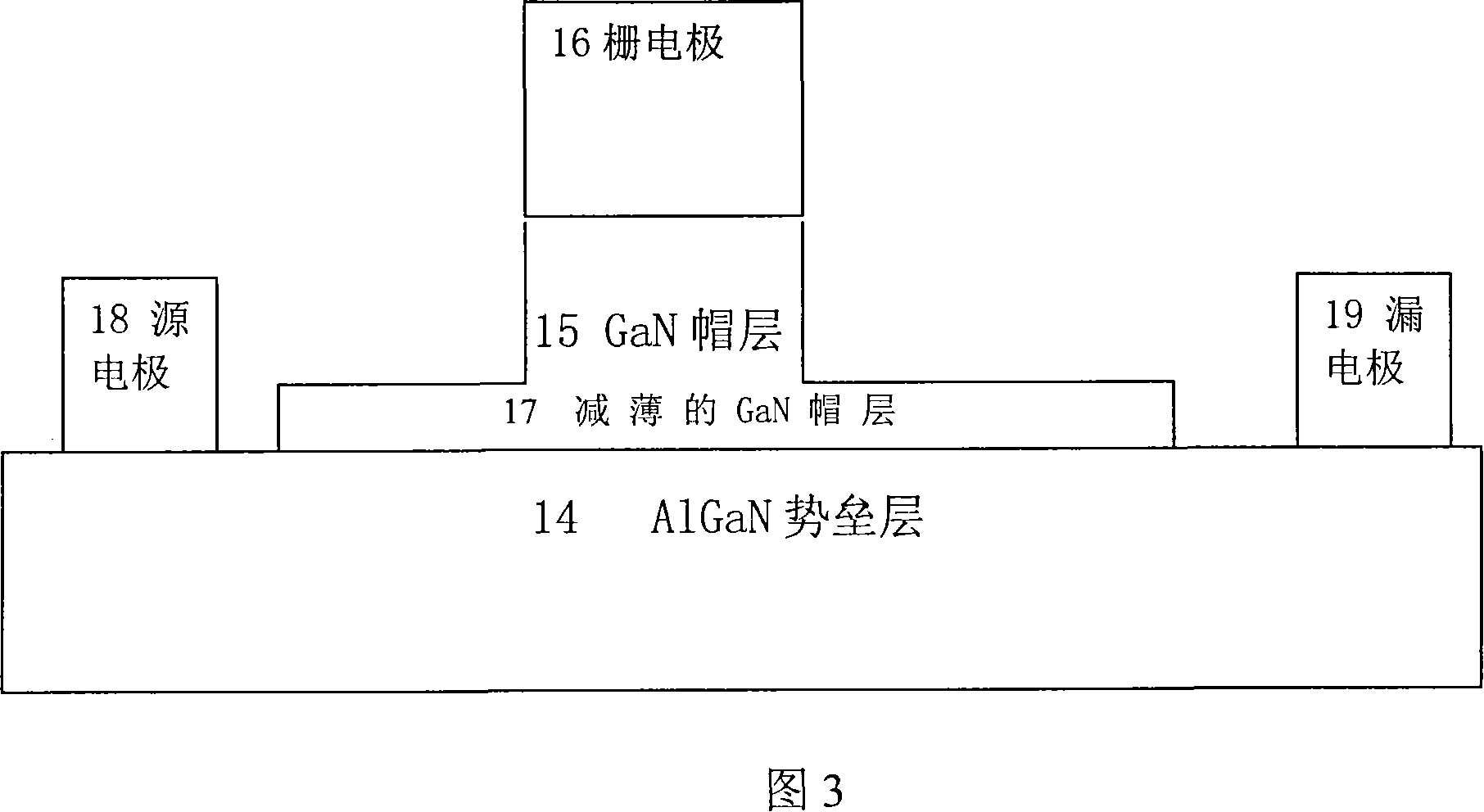

[0025] Select alloy Al with low Al composition ratio 0.04 Ga 0.96 N is the buffer layer 11, grow 10nm undoped GaN as channel layer 12, and then grow 2nm undoped AlN isolation layer 13 and 10nm undoped Al on it 0.35 Ga 0.65 The N barrier layer 14 is finally covered with an 8nm undoped GaN cap layer 15 . Self-consistently solve the Schrödinger equation and Poisson equation to calculate the channel electron gas density as 9.76*10 12 cm -2 , the pinch-off voltage is 4.2V. When the thinned GaN cap layer 17 is 3nm, the calculated electron gas density is 1.32*10 13 cm -2 . A source electrode 18 and a drain electrode 19 are fabricated on the AlGaN barrier layer 14 where the GaN cap layer has been etched completely. After removing the GaN cap layer 15, the electron gas density rises to 1.74*10 13 cm -2 . The electron gas density from the gate to the drain is 9.76*10 12 cm -2 Increased to 1.74*10 13 cm -2 Variation Barrier Field Effect Transistor.

Embodiment 2

[0026] Embodiment 2: select alloy Al with low Al composition ratio 0.04 Ga 0.96 N is the buffer layer 11, grow 10nm undoped GaN as channel layer 12, and then grow 2nm undoped AlN isolation layer 13 and 8nm undoped Al on it 0.4 Ga 0.6 The N barrier layer 14 is finally covered with an 8nm undoped GaN cap layer 15 . Self-consistently solve the Schrödinger equation and Poisson equation to calculate the channel electron gas density as 10.5*10 12 cm -2 , the pinch-off voltage is 4.1V. When the GaN cap layer is thinned to 3nm, the calculated electron gas density is 1.465*10 13 cm -2 . When the GaN cap layer is completely etched, the electron gas density rises to 2.06*10 13 cm -2 . The electron gas density from the gate to the drain is 10.5*10 12 cm -2 Increased to 2.06*10 13 cm -2 Variation Barrier Field Effect Transistor. Compared with the production example 1, after increasing the Al composition ratio of the barrier layer 14, the change span of the electron gas densi...

Embodiment 3

[0027] Embodiment 3: select alloy Al with low Al composition ratio 0.04 Ga 0.96 N is the buffer layer 11, grow 10nm undoped GaN as the channel layer 12, and then grow 2nm undoped AlN isolation layer 13 and 8nm doping concentration to 5*10 18 cm -3 Al 0.35 Ga 0.65 The N barrier layer 14 is finally covered with an 8nm undoped GaN cap layer 15 . Self-consistently solve the Schrödinger equation and Poisson equation to calculate the channel electron gas density as 1.17*10 13 cm -2 , the pinch-off voltage is 4.5V. When the GaN cap layer is thinned to 3nm, the calculated electron gas density is 1.49*10 13 cm -2 . When the GaN cap layer is completely etched, the electron gas density rises to 1.91*10 13 cm -2 . Composed from the gate to the leakage electron gas by 1.17*10 13 cm -2 Increased to 1.91*10 13 cm -2 Variation Barrier Field Effect Transistor. Modulating the doped structure increases the channel electron gas density, and making ohmic contacts on the doped laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com