Production method of solid preparation for degradation of ammonia nitrogen and nitrite

A nitrite and ammonia nitrogen technology, applied in chemical instruments and methods, biochemical equipment and methods, enzymes, etc., can solve environmental problems and achieve the effects of reducing ammonia nitrogen and nitrite nitrogen content, complete degradation, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

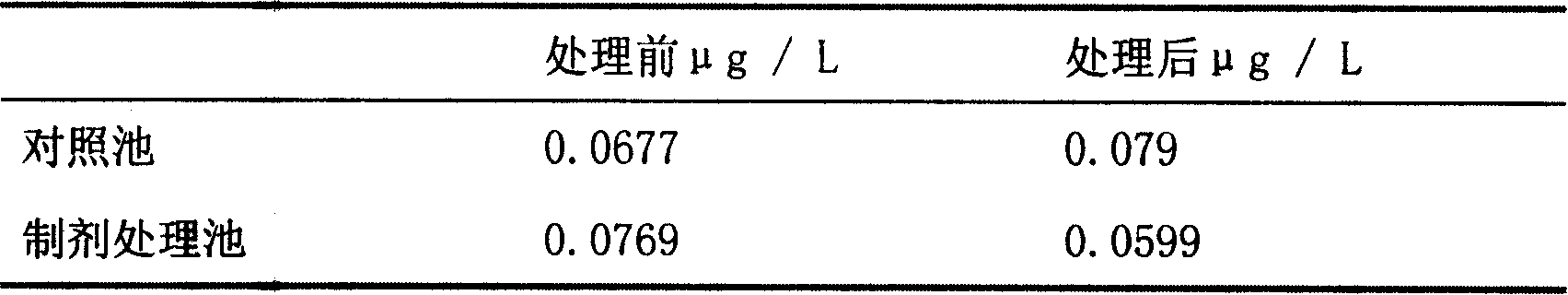

Embodiment 1

[0010] 1. Test plan

[0011] 1. Preparation of composite microorganism and composite enzyme solid preparation

[0012] Take by weight 1% molasses and 0.07% corn steep liquor freeze-dried powder as basic medium, add 0.001% ammonium sulfate again; After dissolving ammonium sulfate, molasses and corn steep liquor freeze-dried powder with water, join in the fermentation tank, add The liquid volume is 70% of the fermenter. After autoclaving for 30 minutes, inoculate after cooling to 33°C, cultivate Bacillus subtilis (37°C), nitrifying bacteria (37°C), photosynthetic bacteria (35°C), denitrifying bacteria (35°C) at different temperatures , saccharomycetes (30°C), actinomycetes (30°C) and other six strains, cultivated for 20 hours, centrifuged the culture solution, collected the thalline, added bran 3 times the weight of the thalline to the thalline, and The mixture of thalline and bran is boiled and dried in a fluidized bed to obtain the dry bacterial powder of the composite micro...

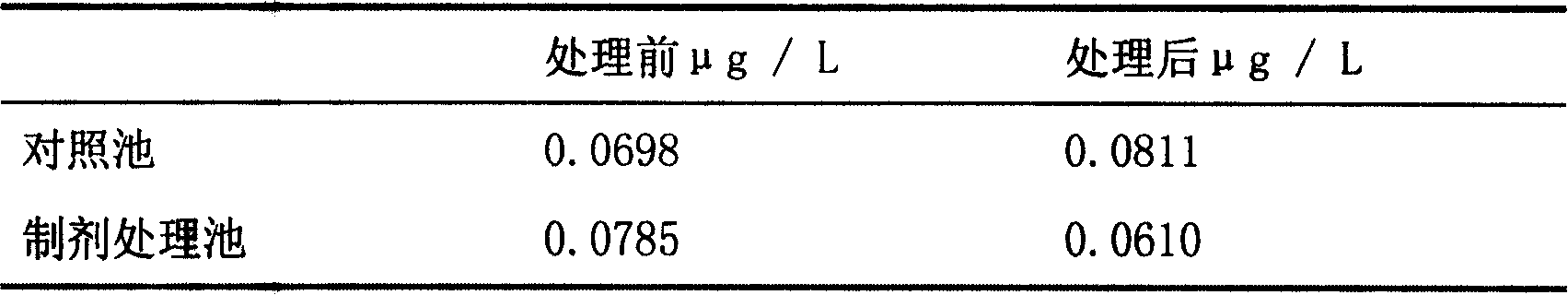

Embodiment 2

[0025] 1. Test plan

[0026] 1. Preparation of composite microorganism and composite enzyme solid preparation

[0027] Take by weight 1.2% molasses and 0.06% corn steep liquor freeze-dried powder as basic medium, add 0.0015% ammonium sulfate again; After dissolving ammonium sulfate, molasses and corn steep liquor freeze-dried powder with water, join in the fermentation tank, add The liquid volume is 70% of the fermenter. Autoclave for 30 minutes, inoculate after cooling to 33°C, cultivate Bacillus subtilis (37°C), nitrifying bacteria (37°C), photosynthetic bacteria (35°C), denitrifying bacteria (35°C) and Six strains of yeast (30°C) and actinomycetes (30°C) were cultured for 22 hours, the culture solution was centrifuged to collect the bacteria, and bran twice the weight of the bacteria was added to the bacteria. The mixture of thalline and bran is boiled and dried in a fluidized bed to obtain a composite microbial dry bacterial powder, then add protease, lipase and amylase ...

Embodiment 3

[0039] 1. Test plan

[0040] 1. Preparation of composite microorganism and composite enzyme solid preparation

[0041]Take by weight 0.9% molasses and 0.09% corn steep liquor freeze-dried powder as basic medium, add 0.0012% ammonium sulfate again; After dissolving ammonium sulfate, molasses and corn steep liquor freeze-dried powder with water, join in the fermentation tank, add The liquid volume is 70% of the fermenter. Autoclave for 30 minutes, inoculate after cooling to 33°C, cultivate Bacillus subtilis (37°C), nitrifying bacteria (37°C), photosynthetic bacteria (35°C), denitrifying bacteria (35°C) and Six strains of yeast (30°C) and actinomycetes (30°C) were cultured for 24 hours, the culture solution was centrifuged to collect the bacteria, and bran four times the weight of the bacteria was added to the bacteria, and the The mixture of thalline and bran is boiled and dried in a fluidized bed to obtain a composite microbial dry bacterial powder, and then protease, lipase ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com