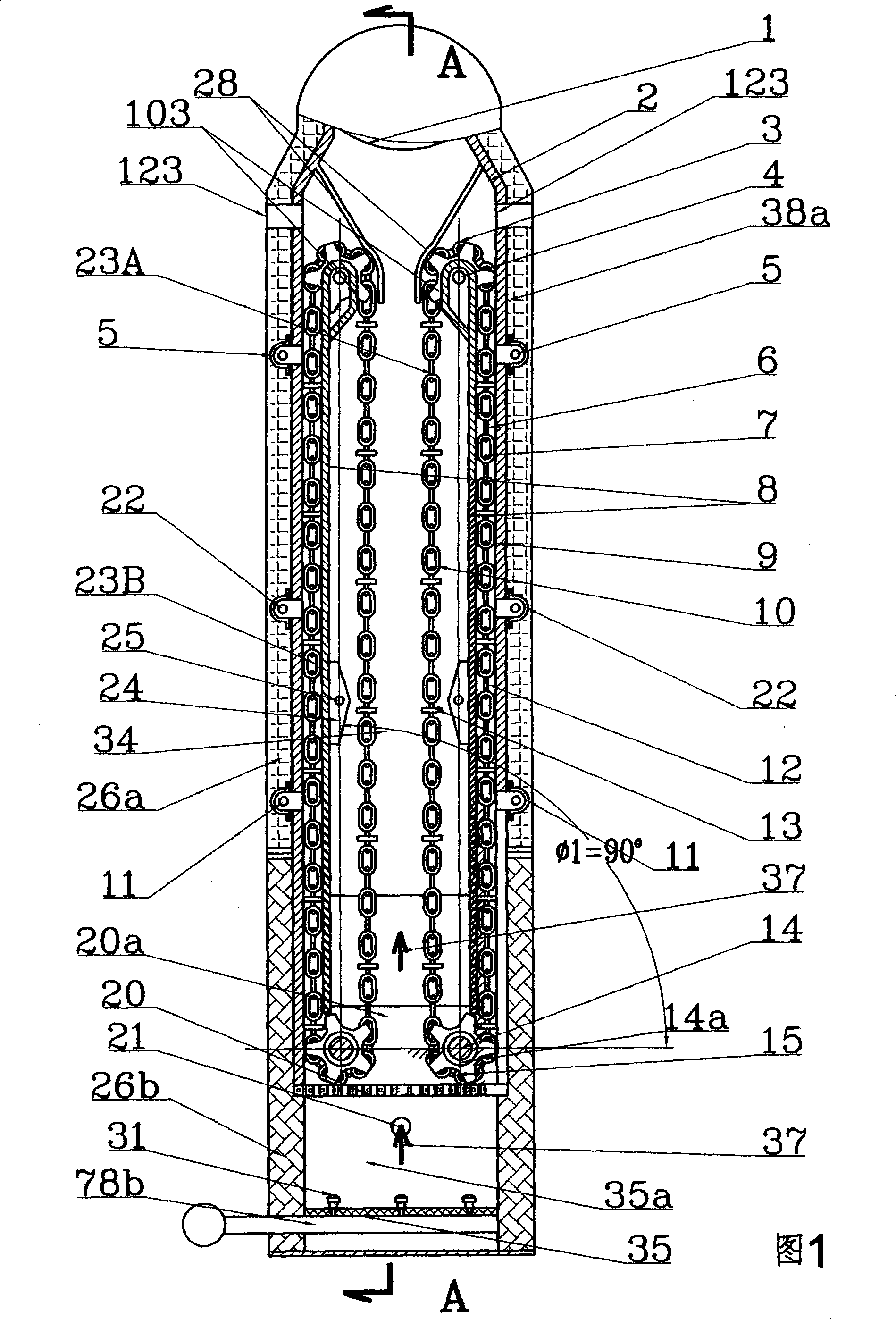

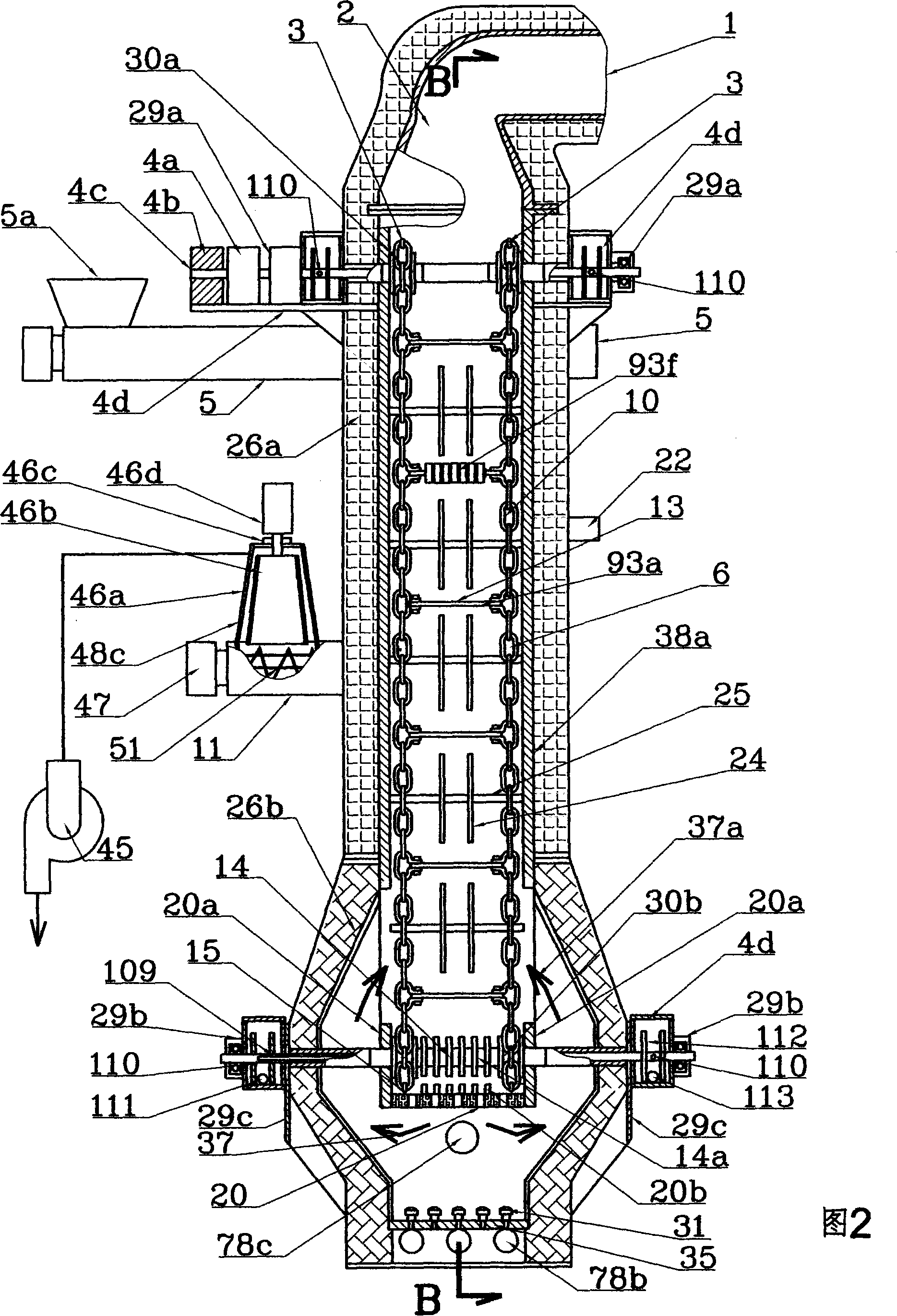

Chain track enterclose type anoxia ebb fried drying, burning and burningcandle decomposition apparatus

A chain and drying technology, applied in the fields of renewable resources and environmental protection, energy and chemical industry, can solve the problems of easy explosion of sludge and dust, complex process, complex structure, etc., and achieve significant energy-saving effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 5

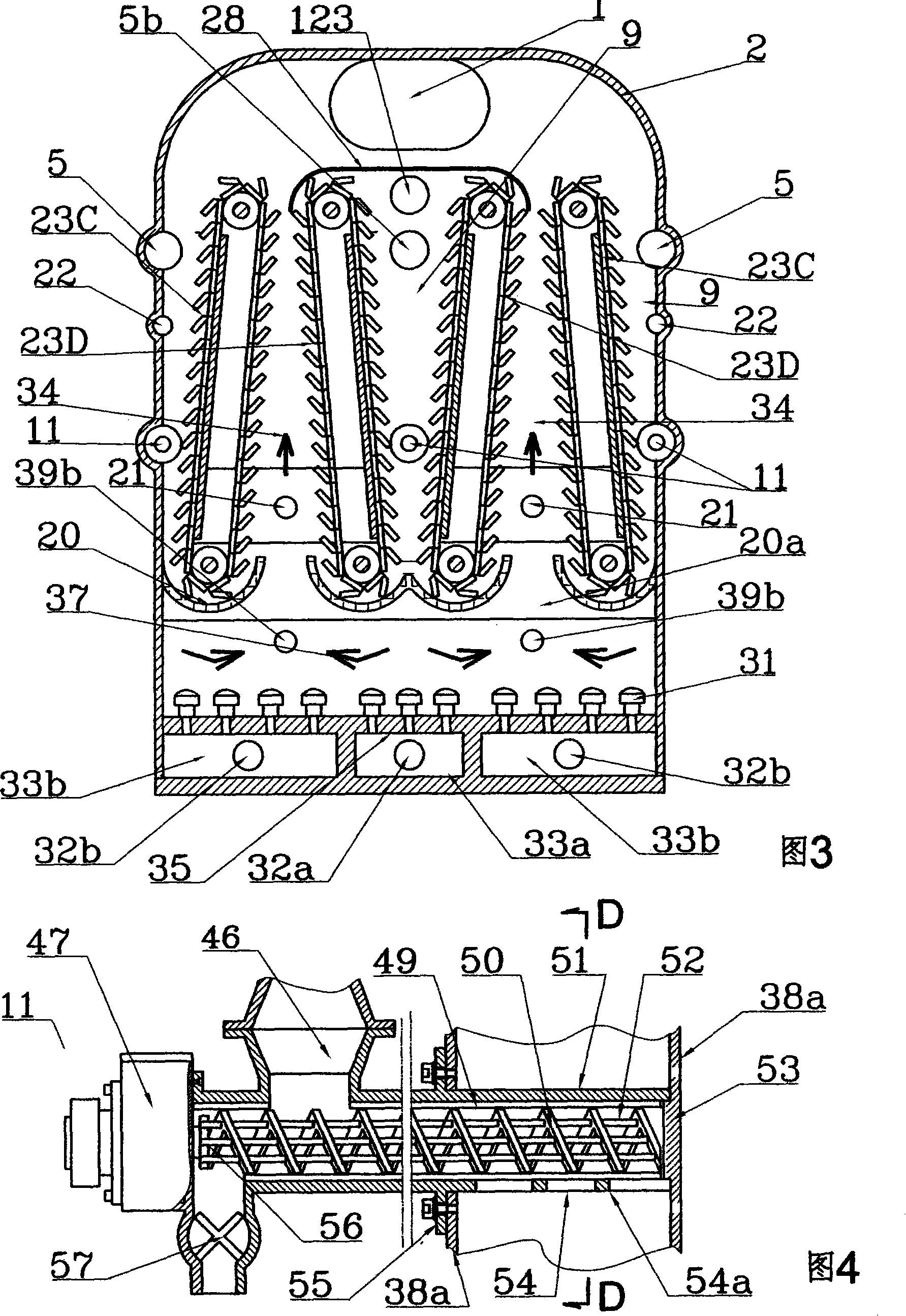

[0076] In Figure 10, the present invention is shown as Example 5 with drying as the main and pyrolysis as the auxiliary;

[0077] The feature of this embodiment is that three pairs of chain heat exchangers 23A, 23B and 23E are arranged in the housing 2, wherein two groups of chain heat exchangers form two pairs of symmetrically inclined chain heat exchangers 23A and 23B, and in addition Two groups of chain heat exchangers form a pair of symmetrical chain heat exchangers 23E; the two uplinks 10 of the pair of symmetrical chain heat exchangers 23E are respectively arranged on the chain cable partition screen 8 and the chain heat exchange In the drying channel 40 formed by the heating vertical wall 38a of the device (23B and 23A); the burner 39 of fluid fuel is arranged on the wall of the drying channel 40 top, and the high-temperature gas produced by the burner 39 passes through the whole process of the drying channel 40 and turns to the lower end. The chain road 15 is discharge...

Embodiment 7

[0080] In Figures 9 and 15, the present invention is shown as Example 7 with drying as the main and pyrolysis as the auxiliary;

[0081] The heat generation subsystem adopts a rotating grate fluidized bed heating furnace, and the fluidized medium is air; on the basis of embodiment 8, a series of air caps 31 are evenly distributed on the plane of the rotating grate 104 to replace the ventilation holes. 31 is a rectangular hollow dead-leg, the dead-end side of the upper part of the dead-leg is uniformly arranged with a series of jet holes, and the cavity at the lower part of the dead-leg is connected to the air distribution chamber 83 .

[0082] Three sets of chain heat exchangers are installed in the constant temperature space, of which two sets of chain heat exchangers 23A and 23B form a pair of symmetrically inclined chain heat exchangers, and the other set of chain heat exchangers 23E’s uplink 10 is arranged in the drying channel 40 that the heating vertical wall 38a of the ...

Embodiment 9

[0087] In Fig. 19, it shows the system of the present invention as raw material dehydration and drying finished products, concurrent production of high-temperature gas external supply, and auxiliary production of liquefied oil, and shows the embodiment 9 of the present invention as drying and pyrolysis oil production: The embodiment 3 or 5 or 8 or 9 of the listed equipment is combined into a system for obtaining liquefied bio-oil by using activated sludge raw material biomass; the sludge with a temperature of 15-25 ° C, a grain size ≤ 3mm, and a water content of 50-65% The auger of the feeding subsystem is added to the inlet 5 of the water evaporation section of the downlink of the chain heat exchanger. The heat generation subsystem adopts a fluidized bed heating furnace, and the temperature of the hot air flow in the heat generation subsystem is 400-500 ℃, pyrolysis reaction pressure (gauge pressure) 0.02Mpa; the high-temperature combustion gas passes through the chain cable p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com