Acid for corroding sandstone

A sandstone and erosion technology, applied in the field of chemical agents, can solve problems such as strong corrosion, reduced production increase effect, and fast response speed, and achieve low odor, low formation damage, and low corrosive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

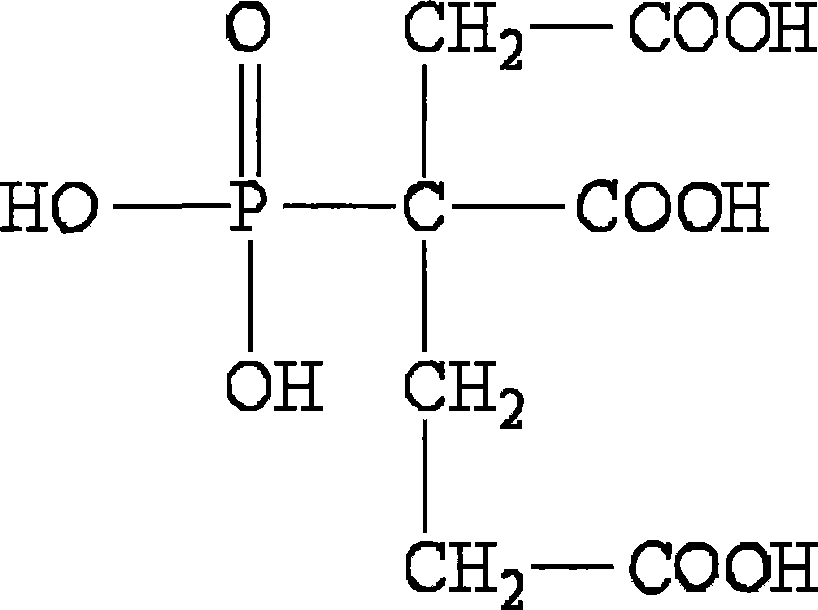

[0023] Phosphate complex 10%

[0024] Ammonium Bifluoride 10%

[0025] Acetic acid 2%

[0026] Citric Acid 1%

[0027] Alamine Condensation Polymer 1%

[0028] Ethylene glycol monobutyl ether 1%

[0029] Polyoxyethylene ether nonionic surfactant 1%

[0030] Polydimethylallylamine 2%

[0031] Water is 72%.

[0032] The acid for etching sandstone of the present invention is prepared by mixing the above-mentioned components.

Embodiment 2

[0034] Phosphate complex 15%

[0035] Ammonium Bifluoride 15%

[0036] Acetic acid 3%

[0037] Citric acid 2%

[0038] Tetramethylpyridine and benzyl chloride polymer 3%

[0039] Nonionic Chlorine Surfactant 5%

[0040] Polyoxygen silicone nonionic surfactant 2%

[0041] Polydimethyldiallylammonium Chloride 5%

[0042] Water is 50%.

[0043] The acid for etching sandstone of the present invention is prepared by mixing the above-mentioned components.

Embodiment 3

[0045] Phosphate complex 20%

[0046] Ammonium bifluoride 20%

[0047] Acetic acid 1%

[0048] Citric acid 0.5%

[0049] Piperazine blend with alkylbenzyl polymer 0.5%

[0050] Ethylene glycol monobutyl ether 2%

[0051] Polyoxyethylene ether nonionic surfactant 0.5%

[0052] Polyepichlorohydrin Dimethylamine 0.5%

[0053] Water is 55%.

[0054] The acid for etching sandstone of the present invention is prepared by mixing the above-mentioned components.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com