Method for producing aluminum oxide titanium white series multiple phase fine ceramics material

A technology of fine ceramics and alumina, which is applied in the field of preparing alumina/titanium oxide complex-phase fine ceramic materials, which can solve the problems of low density of ceramic green bodies, reduce production costs, and high sintering temperature, and achieve uniform quality and repeatability Good, reduce the effect of sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

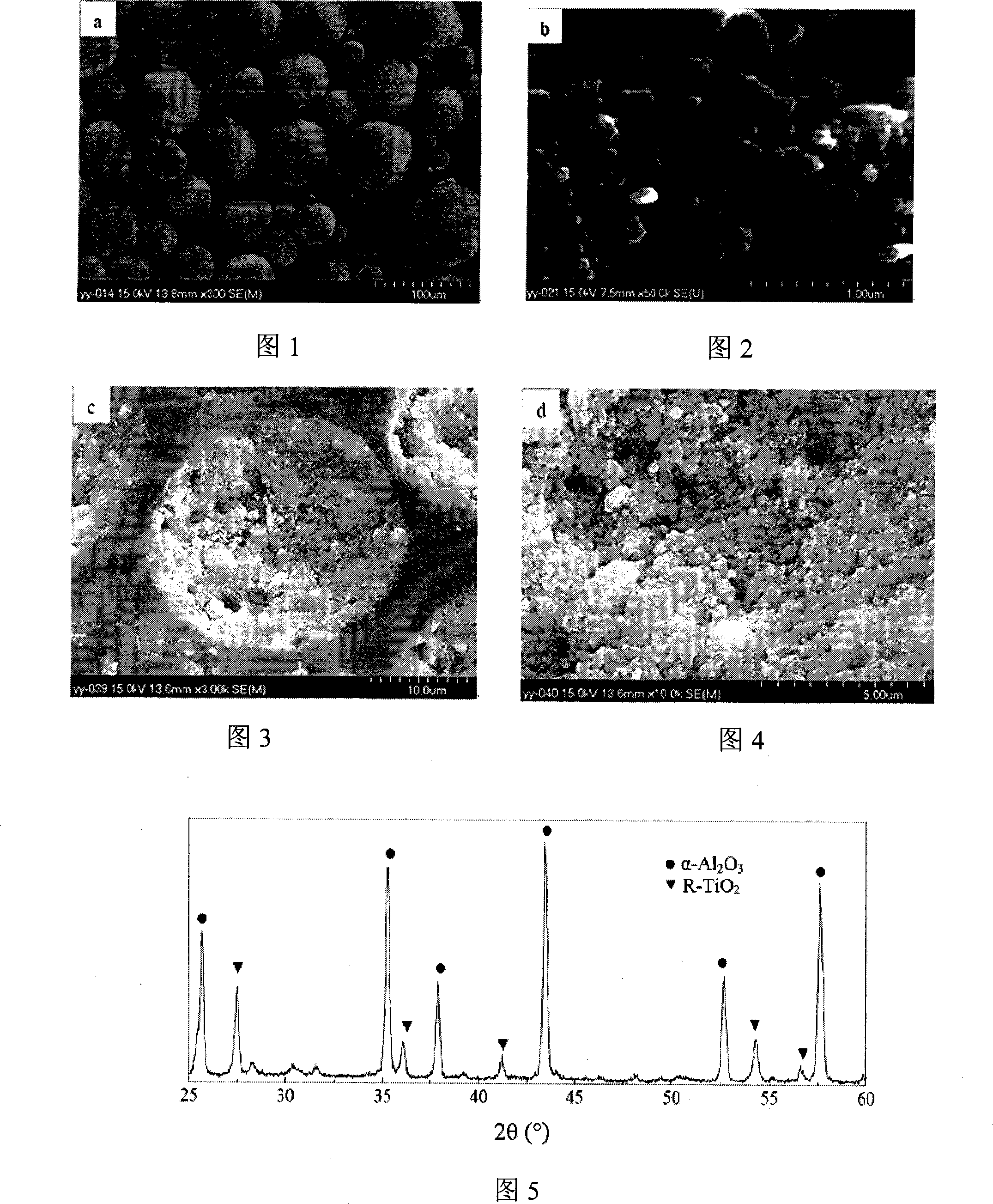

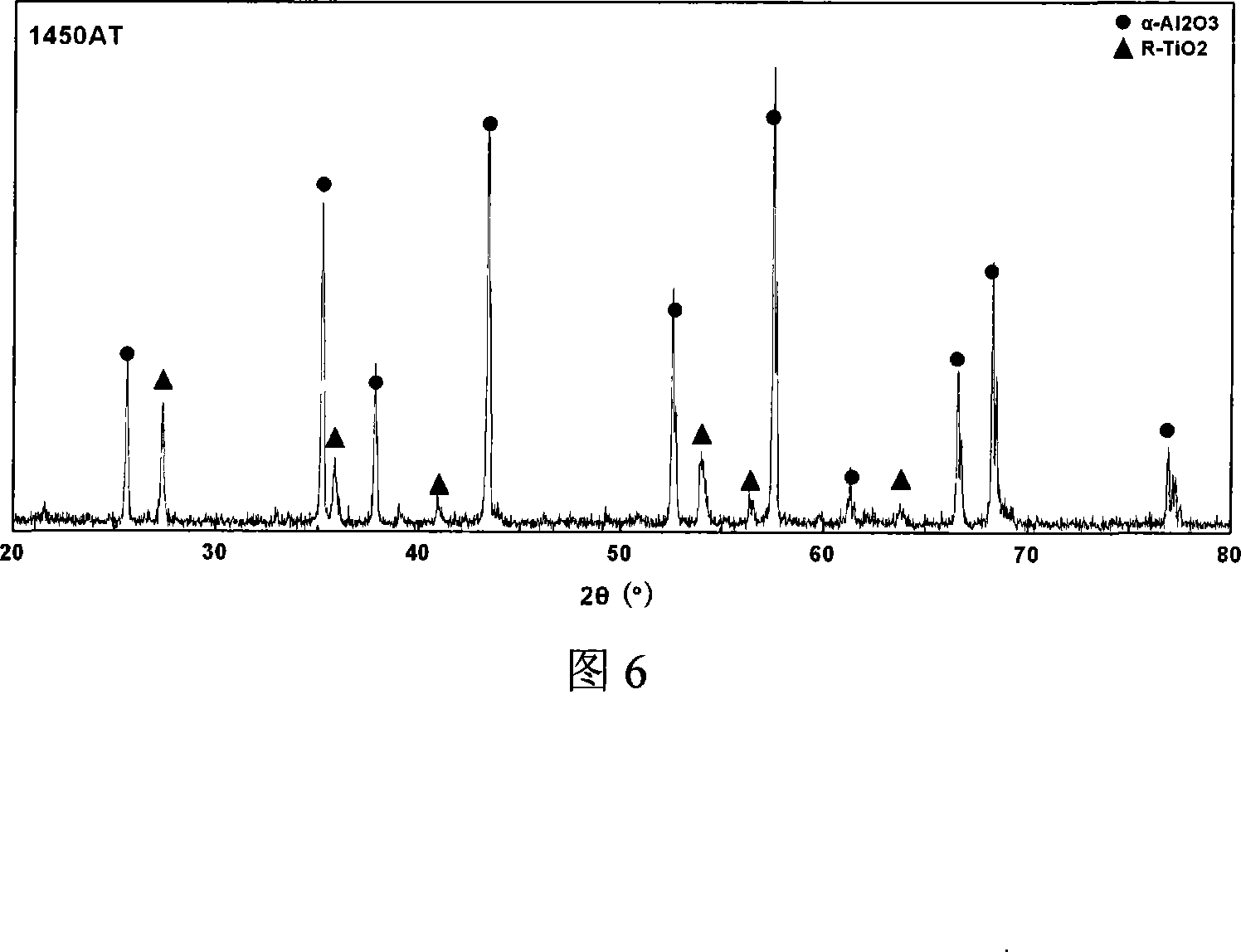

[0009] Specific embodiment one: the method for preparing alumina / titanium oxide complex phase fine ceramics in this embodiment is implemented according to the following steps: 1. Mix powder, deionized water, binder polyvinyl alcohol (PVA) and grinding balls Put it into the ball mill according to the mass ratio of 1:0.4~0.6:0.01~0.015:3~5, and mix it at 1000~1200rpm for 4~10h. The mixed powder is composed of 50~99% nano-alumina and 1-50% of nano-titanium oxide; 2. Spray-dry and re-granulate the slurry obtained after mixing step 1 to obtain a powder with a particle size of 20-80 μm, and the inlet temperature of the spray dryer is 210-240°C when it is working , the outlet temperature of the spray dryer is 100-120°C, and the nozzle speed of the spray dryer is 35000-37000r / min; 3. Put the regranulated powder into an alumina crucible and put it into a resistance furnace for heat treatment. The process is as follows: the heating rate during the heat treatment is 8-12°C / min; first, th...

specific Embodiment approach 2

[0012] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the mixed powder in step 1 is composed of 60-99% of nano-alumina and 1-40% of nano-titanium oxide by mass percentage. Other reactions are the same as in Embodiment 1.

specific Embodiment approach 3

[0013] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the mixed powder in step 1 is composed of 70-97% of nano-alumina and 3-30% of nano-titanium oxide by mass percentage. Other reactions are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com