Method for eliminating error when measuring vanadium by ferrous ammonium sulfate capacitance method

A technology of ammonium ferrous sulfate and volumetric method, which is applied in chemical analysis by titration method, material analysis by observing the influence on chemical indicators, and analysis by making materials undergo chemical reactions, etc., which can solve errors, rework, Burette overflow titration and other problems, to achieve the effect of expanding the scope of application, reducing rework rate, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

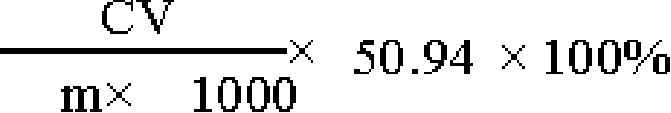

Method used

Image

Examples

Embodiment 1

[0016] Example 1 Titration Excessive Mistake Remedial Method

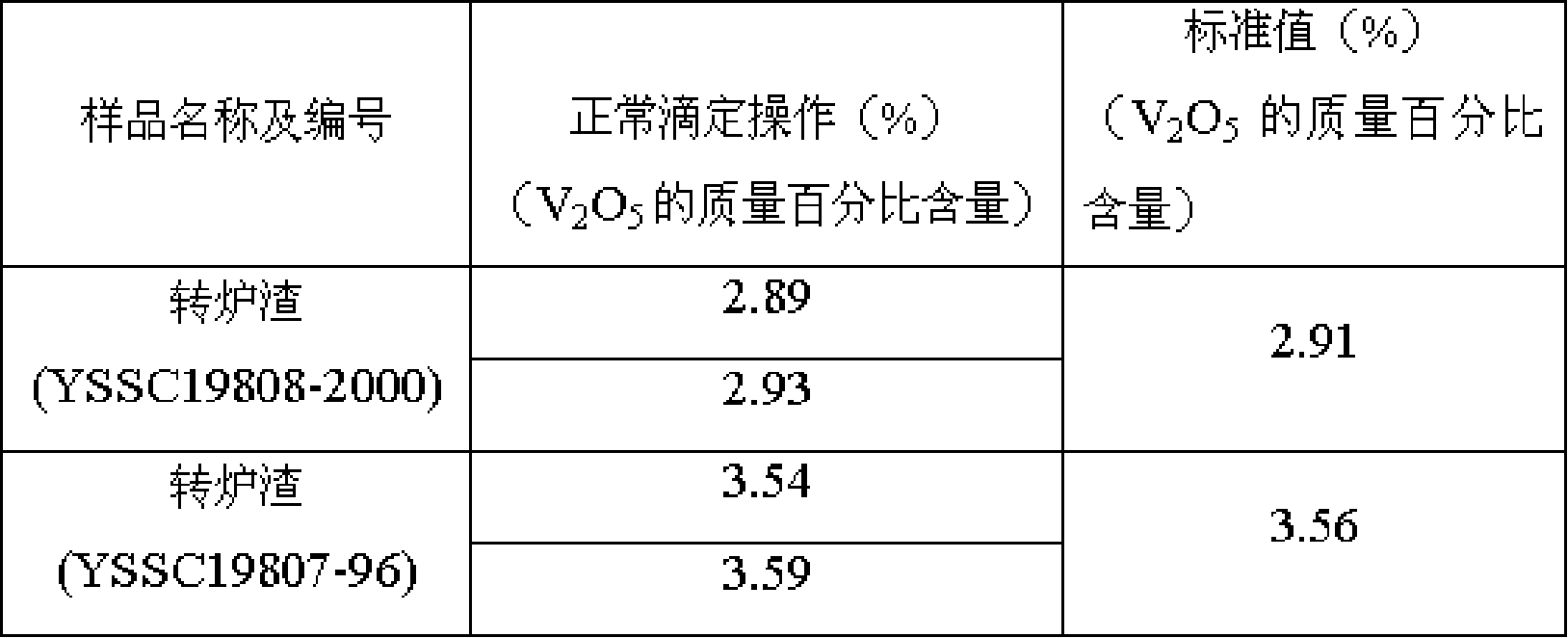

[0017] Two standard samples of converter slag were used for titration operation, and the same sample was subjected to two parallel titrations respectively. The results obtained are shown in Table 1. The standard value is the value given on the standard sample of converter slag.

[0018] Table 1

[0019]

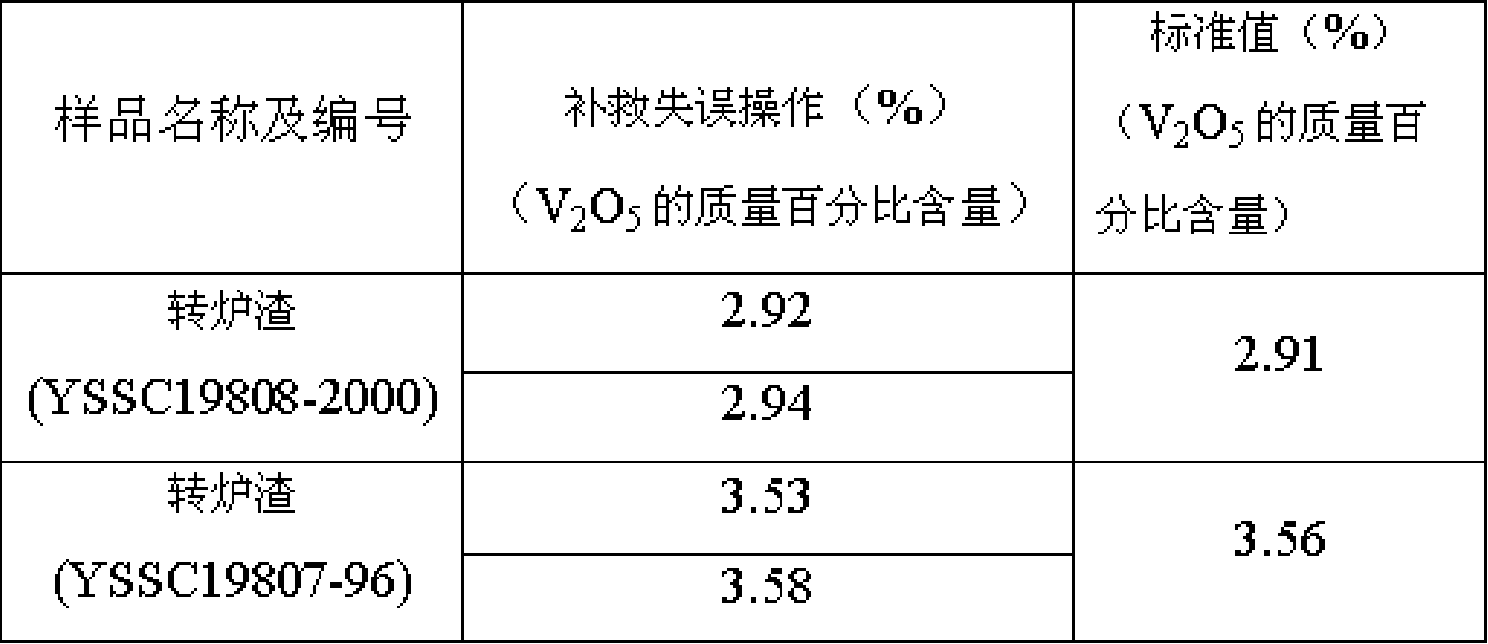

[0020] When there are operational errors such as excessive titration of the solution to be tested, mismatch between the selected ferrous ammonium sulfate concentration and the vanadium content, burette overflow, etc., use 20g / L potassium permanganate solution to adjust the solution to be tested to have a stable dimanganese When manganese precipitate appears, let it stand for 3 minutes; add 0.8 g of urea, adjust it with 20g / L sodium nitrite solution until the manganese dioxide precipitate disappears, add 1-2 drops in excess, let stand for 2 minutes; then add 2g / L N-phenyl-o-amino Benzoic acid is an indicator, a...

Embodiment 2

[0024] Example 2 The titration method of the sample beyond the national standard measurement range

[0025] The national standard (GS / T8704.5-94) method uses the potentiometric titration method for the determination of vanadium in ferrovanadium. If the vanadium in ferrovanadium or vanadium nitride is determined by the ferrous ammonium sulfate volumetric method, it is very difficult to It is difficult to judge the concentration range that the standard solution should be selected, so it is usually wrong to choose, which is time-consuming and inaccurate. In this case, take the following remedial measures to ensure the accuracy of the results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com