Production method for P type gallium nitride electrode

A gallium nitride and electrode technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of low specific contact resistivity, large contact resistance, and small light absorption of P-GaN electrodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

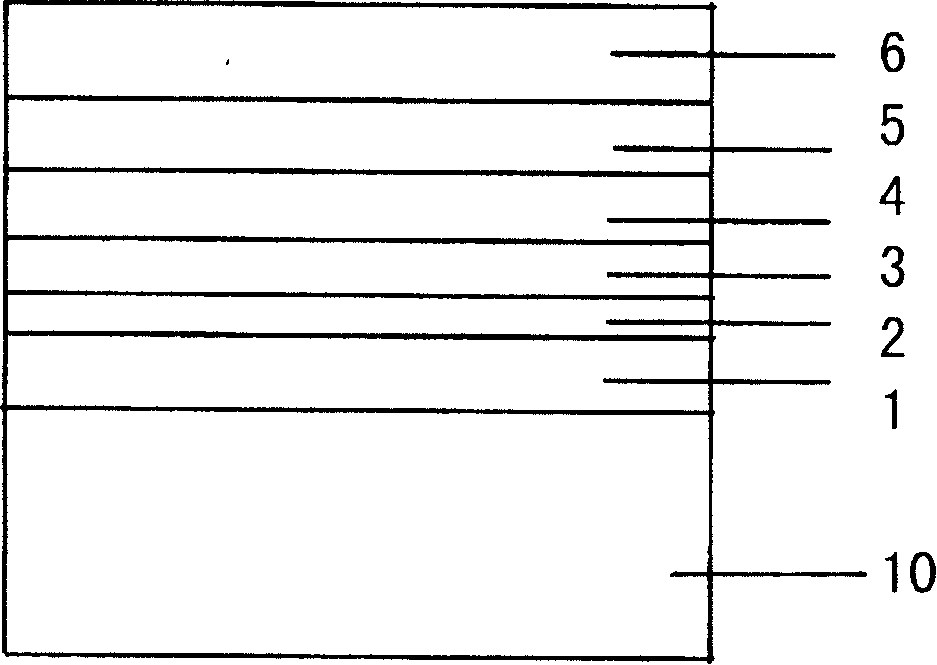

[0019] The electrode of the present invention is made of bonding protection layer Au6, barrier layer Pt5, high reflection mirror Ag4, adhesion layer Ni3, semi-transparent ohmic contact layer Ru / Ni2 and Mg-doped P-GaN layer 1 etc., as figure 1 As shown, the specific preparation steps of the preparation method of a P-type gallium nitride electrode of the present invention are as follows:

[0020] 1) Prepare a sapphire substrate 10 with a thickness of 1 μm and a Mg doping concentration of 5*1017 cm by ordinary metal-organic chemical vapor deposition (MOCVD) or molecular beam epitaxy (MBE) -3 P-GaN substrate 1;

[0021] 2) The sample is cleaned by chemical cleaning methods: scrubbing with acetone cotton ball, soaking in aqua regia for 15 minutes, HCl:H 2 O=1:1 Soak for 5min, boil in ethanol for 5min and rinse with deionized water, wash with dry N 2 Blow dry to achieve the purpose of removing oxides, organic ions, metal particles and water vapor on the surface during material gro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com