Amides Ir organometallic complex electroluminescent material and uses thereof

A metal-organic and complex technology, applied in the field of amide-type Ir metal-organic complex phosphorescent electroluminescent materials, can solve the problems of poor anti-crystallization performance and thermal decomposition, and achieve the effects of low cost, easy synthesis and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

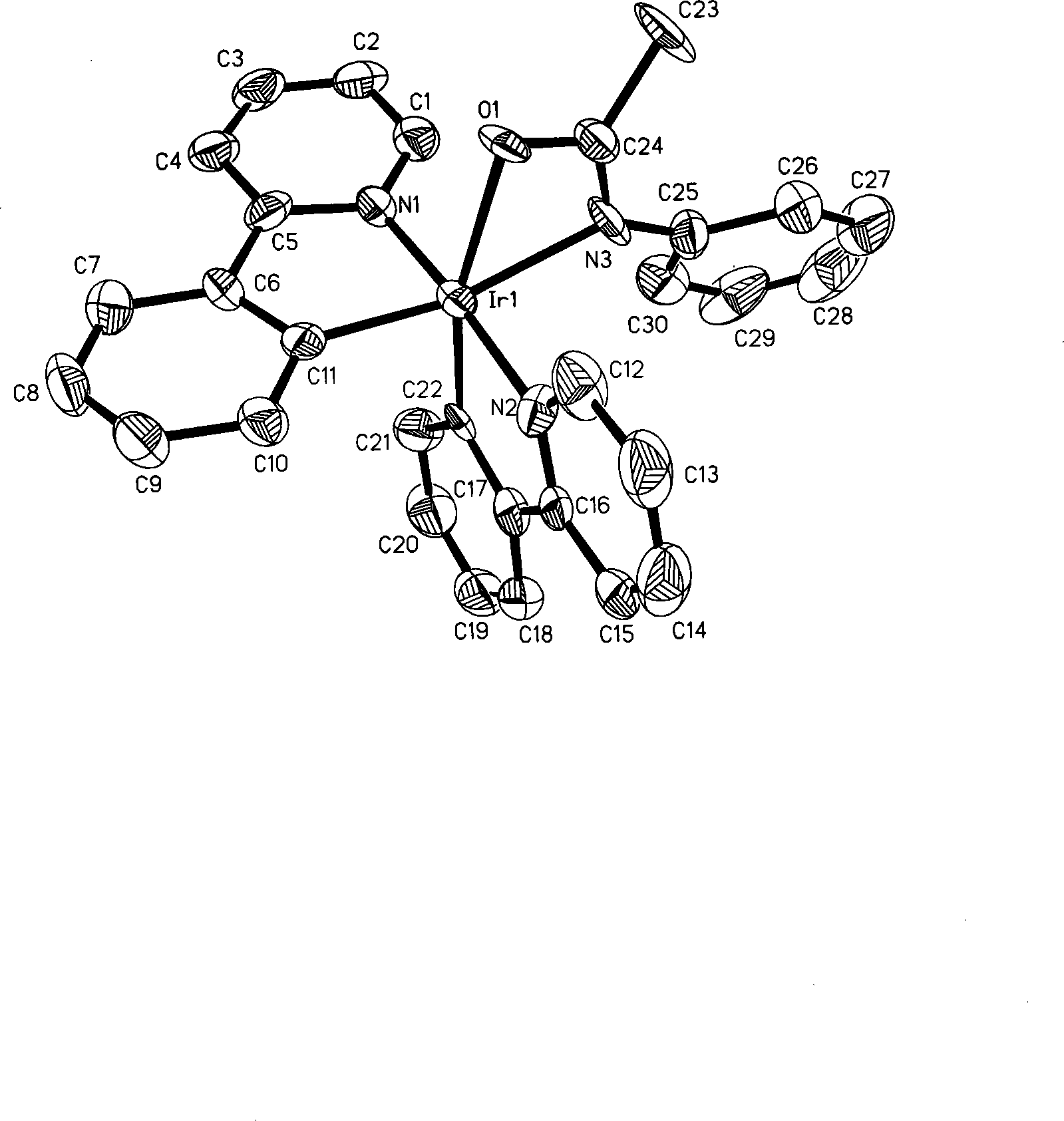

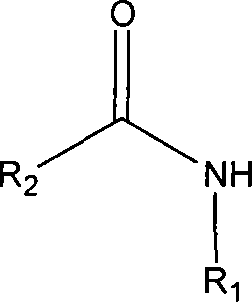

[0022] The preparation method of the metal iridium complex of the present invention: first reflux aniline or aniline derivatives with acid anhydrides or acid chlorides with acetic acid as a solvent to obtain amides, and then with 2-phenylpyridine derivatives L 2 The second bridge compound (L 2 ) 2 Ir(μ-Cl) 2 Ir(L 2 ) 2 Ligand exchange reaction was carried out under alkaline conditions to obtain the target product (L 2 ) 2 Ir(ayl). The specific reaction is as follows:

[0023] (1) Synthesis of amides:

[0024] Synthesis of acetaniline: Aniline, 4-methylaniline, 2,6-dimethylaniline and acetic anhydride were refluxed in acetic acid at a molar ratio of 1:2 for 4 hours, and the reaction solution was poured into ice water to precipitate solid, and then suction filtered, and the obtained solid can be obtained by recrystallization in ethanol.

[0025] Synthesis of 4-bromoacetanilide: use acetanilide as raw material, drop a little excess bromine into it, reflux under acetic a...

Embodiment 1

[0033] Embodiment 1: the auxiliary ligand is acetanilide, and the main ligand is the metal iridium complex of 2-phenylpyridine (L 2 ) 2 The synthesis of Ir (ayl), its structural formula is as follows:

[0034]

[0035] (1) Preparation of Acetanilide:

[0036]In the 100ml round bottom flask, add 9.3 grams of newly distilled aniline and 20ml of acetic acid, then add dropwise 5.1 grams of acetic anhydride under stirring, heat to reflux at 120 degrees, and stop the reflux after four hours of reflux. After cooling, the reaction solution was poured into ice water, a large amount of white solid was precipitated, filtered with suction, and the obtained white solid was dissolved in 100ml of ethanol to crystallize. Obtained 10.9 g of colorless flaky crystals (yield 81.0%), m.p=125°C

[0037] (2) Two-bridge compound (ppy) 2 Ir(μ-Cl) 2 Ir(ppy) 2 Synthesis:

[0038] Take 0.568 iridium trichloride hydrate and 0.725 g of 2-phenylpyridine, add them to a mixed solvent of 30 ml of 2-...

Embodiment 2

[0041] Embodiment 2: the auxiliary ligand is 4-bromoacetanilide, and the main ligand is the synthesis of metal iridium complexes of 2-phenylpyridine, and its structural formula is as follows:

[0042]

[0043] (1) Preparation of 4-bromoacetanilide

[0044] Add 1.530 g of acetanilide to a 100 ml three-necked flask, add 30 ml of acetic acid to dissolve, take 0.8 ml of liquid bromine, dissolve it in 10 ml of acetic acid to make a solution, and slowly add the bromoacetic acid solution to the acetanilide solution dropwise at a temperature of 40°C Within an hour, the drop is over. After the dropwise addition was completed, the reaction was maintained at 40°C for one hour, and then the temperature was raised to 60°C for two hours. After cooling, pour the reacted solution into a beaker, add a small amount of sodium thiosulfate until the reaction solution is colorless, then pour the solution into ice water, and a large amount of white solids are precipitated. After suction filtrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com