Preparation method of carbon nanometer tube/ polyimide composite fiber

A technology of carbon nanotubes and composite fibers, which is applied in the field of preparation of composite fibers, and can solve problems such as the mechanical properties of fibers that are difficult to spin and form, and the interfacial adhesion of uneven dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

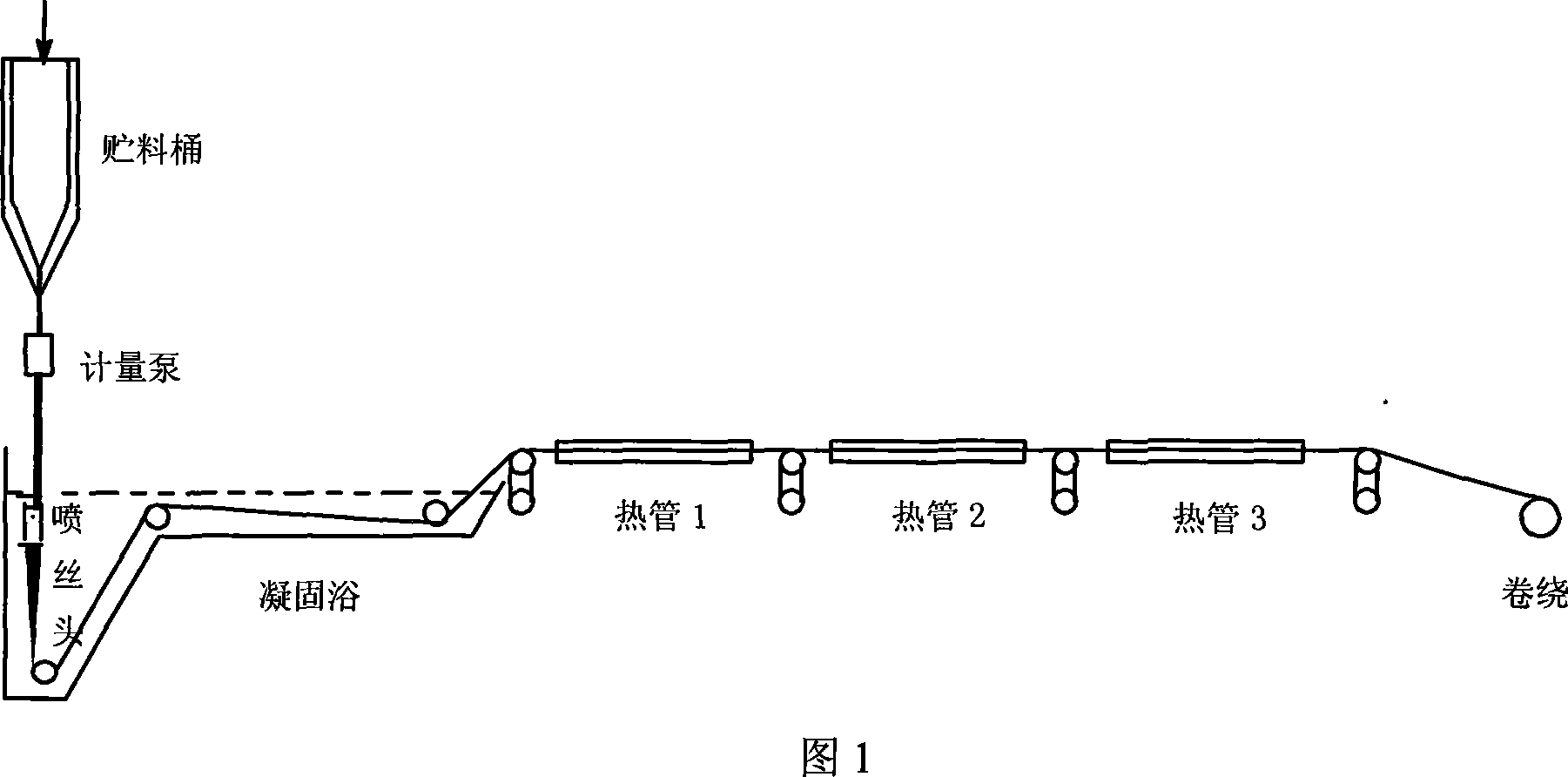

Method used

Image

Examples

Embodiment 1

[0026] (1) Add 6g of multi-walled carbon nanotubes into 120ml of mixed acid of 70% concentrated nitric acid and 98% concentrated sulfuric acid (volume ratio is 1:3), ultrasonicate at 60°C for 2h, then reflux in a water bath at 60°C for 5h, After cooling to room temperature, slowly add deionized water to soak for about 10 hours, pour off the supernatant, add deionized water, use a high-speed centrifuge to wash and separate, and wash with water for several times until the pH value of the product is greater than 6; finally wash it clean The carbon nanotubes were dried in an oven for 48 hours to obtain acidified multi-walled carbon nanotubes MWNTs-COOH. Take by weighing 4g of MWNTs-COOH in a 500ml volumetric flask, add 80ml of N, N-dimethylacetamide (DMAc), ultrasonic 30min; weigh 12g of octadecyl isocyanate (C 18 h 37 NCO) in a 400ml beaker, add 200ml of DMAc solvent, stir until completely dissolved; 200ml of C 18 h 37 Add the DMAc solution of NCO into the DMAc suspension of M...

Embodiment 2

[0031] (1) The multi-walled carbon nanotubes used in step (1) in Example 1 are replaced by single-walled carbon nanotubes, octadecyl isocyanate is replaced by p-chlorophenyl isocyanate, N, N'-dimethylacetamide Change to N, N'-dimethylformamide, and other steps are the same as in Example 1.

[0032](2) Add 250ml of N,N'-dimethylformamide solvent in the flask, pass nitrogen gas for deoxygenation protection, add 24.0288g of diaminodiphenylmethane, mechanically stir until completely dissolved, and add 26.1744 g of pyrobenzene in batches sulfuric anhydride, and stirred for 4 h under an ice bath to obtain a pale yellow polyamic acid (PAA) solution with a solid content of 17%.

[0033] (3) Weigh 1.5 g of alkylated carbon nanotubes, put them into a sample bottle, add 18 ml of N, N'-dimethylformamide solvent, and ultrasonically disperse the carbon nanotubes in the solvent for 2 hours, and the alkylated Add the N, N'-dimethylformamide solution of the carbon nanotubes to the above-menti...

Embodiment 3

[0036] (1) The multi-walled carbon nanotubes used in step (1) in Example 1 are replaced by double-walled carbon nanotubes, and octadecyl isocyanate is replaced by 3,4-dichlorophenylisocyanate, N,N'-dimethyl Base acetamide is changed into N-methylpyrrolidone, and other steps are with embodiment 1.

[0037] (2) Add 150ml of N-methylpyrrolidone solvent in the flask, nitrogen deoxygenation protection, add 24.0288g 4,4,-diaminodiphenyl sulfide, mechanically stir until completely dissolved, add 26.1744g of biphenyl in batches Tetraformic acid dianhydride was stirred for 5 h under an ice bath to obtain a light yellow polyamic acid (PAA) solution with a solid content of 25%.

[0038] (3) Weigh 2.5g of alkylated carbon nanotubes, put them into a sample bottle, add 20ml of N-methylpyrrolidone solvent, and ultrasonically 2h, so that the carbon nanotubes are dispersed in the solvent, and the alkylated carbon nanotubes Add the N-methylpyrrolidone solution of the tube into the above-mentio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com