Bisphenol A(phenyl polyphosphoric acids easter) flame retardant and preparation thereof

A technology of polyphosphate and flame retardant, applied in the direction of fire retardant coatings, etc., can solve the problems of reduced flame retardant effect, poor product surface quality, poor compatibility, etc., and achieve the effect of improving impact strength and ensuring flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

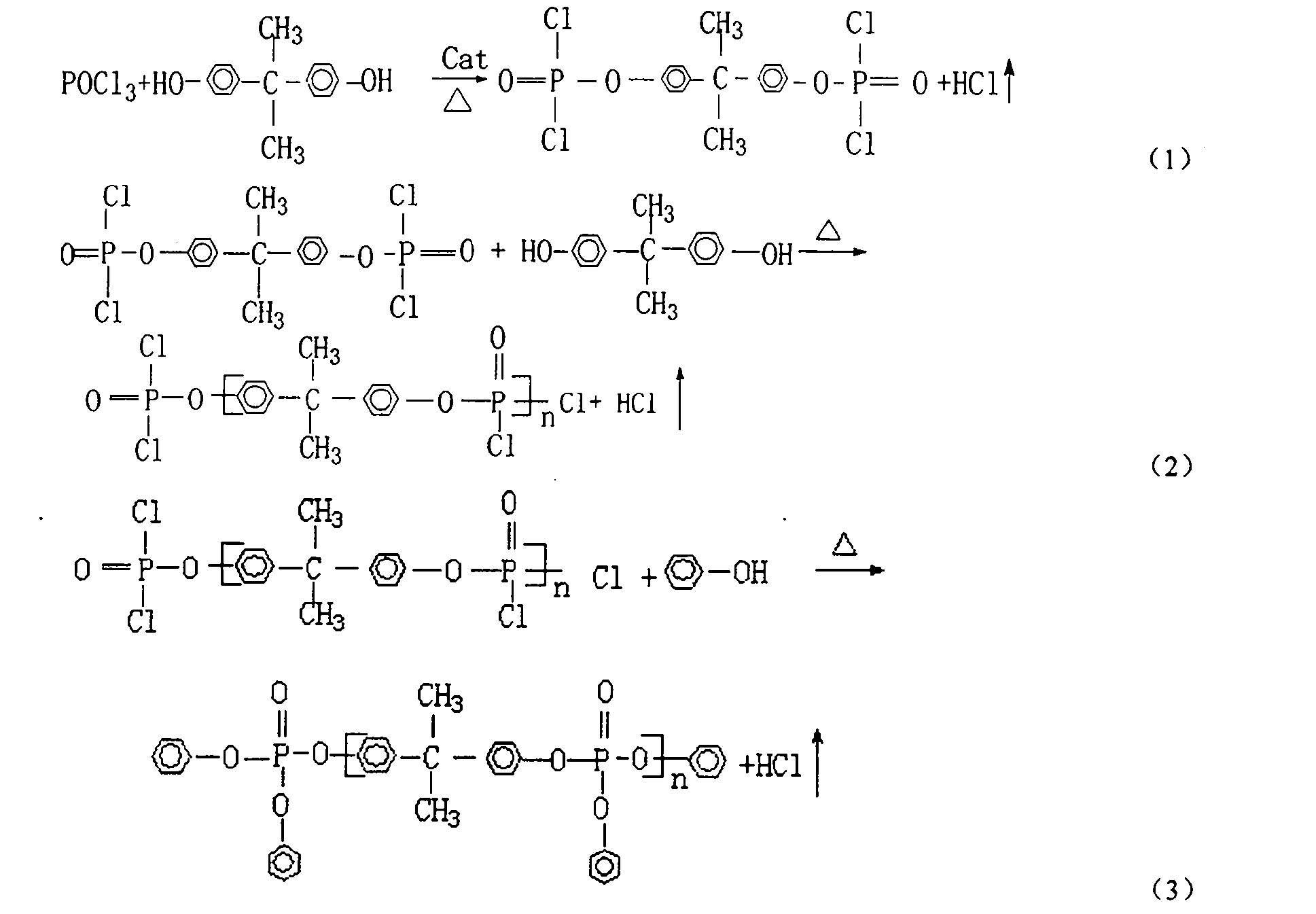

Method used

Image

Examples

Embodiment 1

[0018] The first step is the synthesis of intermediate monomers: 460g phosphorus oxychloride (POCl 3 ) Put into a four-neck flask with stirring and thermometer, add a small amount of Lewis acid catalyst, stir and heat to about 100℃, add 228g of bisphenol A in batches, keep the temperature for 3-4 hours, and collect the hydrogen chloride produced by the reaction Gas (such as water absorption), gradually increase the temperature to reflux and continue the reaction for 2 hours, until no HCl escape is detected (the reaction ends). Distill out unreacted POCl under reduced pressure 3 , 462g of intermediate product monomer was obtained.

[0019] The second step of polycondensation: Put 210g of bisphenol A into the prepared intermediate monomer at 110°C in batches, react for 3-4 hours, collect the hydrogen chloride gas produced by the reaction, raise the temperature to 140-150°C, and continue the reaction for 3 hours Above, until no HCl escape is detected (reaction equilibrium), 639 g of...

Embodiment 2

[0022] Example 2: Same as Example 1. After the intermediate product monomer is obtained by the reaction in the first step, double the amount of xylene solvent of the intermediate product monomer is added, and the second, third, and fourth steps are followed. The obtained solid flame-retardant resin has an average molecular weight of 6,500.

Embodiment 3

[0023] Example 3: Same as Example 1. After the intermediate product monomer is obtained by the reaction in the first step, 1.5 times the amount of triethyl phosphate (TEP) solvent is added to the intermediate product monomer, and then the second, third, and fourth steps are followed. At the same time, the reaction temperature in the second step was increased to 155-165°C. The obtained solid flame-retardant resin has an average molecular weight of 10,500.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com