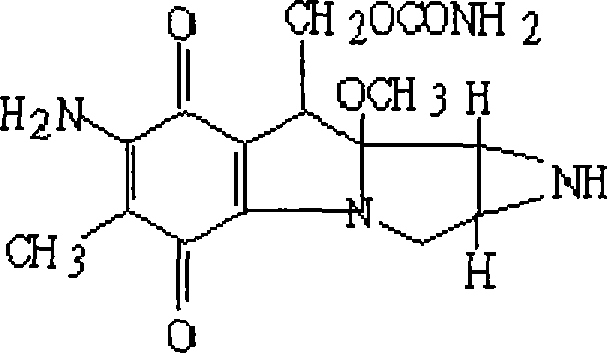

Mitomycin double sustained release film of implanted antineoplastic agents and its preparation method

A technology of drug mitomycin and double sustained release, which is applied in the direction of antitumor drugs, drug combinations, non-active components of polymer compounds, etc. problem, to achieve the effect of improving burst release phenomenon, easy repeatability, and delaying biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Take 40g of collagen stock solution (collagen solid content 1.25%), dissolve in 0.1% acetic acid solution, stir well, and prepare collagen solution; take 125mg of chitosan (molecular weight 400,000, degree of deacetylation 85%) stirring in the acetic acid solution to prepare a chitosan solution; mixing the collagen solution and the chitosan solution and stirring evenly to prepare a collagen-chitosan solution for later use. Dissolve 300 mg of lecithin in 5.0 ml of DMSO, dissolve 60 mg of mitomycin in 1.0 ml of DMSO, mix the two, and lyophilize to obtain a gel-like mixture. Dissolve 600 mg of PLA with a molecular weight of 50,000 in 10 ml of dichloromethane, and add the PLA solution dropwise to the colloidal mixture under stirring conditions to form a uniform reverse micellar solution; Slowly inject 45ml of 0.5% PVA solution to make O / W emulsion. Stir the O / W emulsion at room temperature for more than 6 hours to volatilize the organic solvent, centrifuge, and freeze-dry ...

Embodiment 2

[0041] Take 20g of collagen stock solution (collagen solid content 1.25%), dissolve in 0.3% malonic acid solution, stir well, and prepare collagen solution; get chitosan (molecular weight: 400,000, degree of deacetylation: 85%) stirring in 1% acetic acid solution to prepare a chitosan solution; mixing the collagen solution and the chitosan solution and stirring evenly to prepare a collagen-chitosan solution for later use. Dissolve 100 mg of lecithin in 5.0 ml of DMSO, dissolve 10 mg of mitomycin in 0.5 ml of DMSO, mix the two, and lyophilize to obtain a gel-like mixture. Dissolve 300 mg of PLA with a molecular weight of 5000 in 6 ml of dichloromethane, and add the PLA solution dropwise to the colloidal mixture under stirring to form a uniform reverse micellar solution; ultrasonicate the gained reverse micellar solution in an ice bath (200w, Slowly inject 30ml of 0.5% PVA solution under the condition of 60s) to prepare O / W emulsion. Stir the emulsion at room temperature for mo...

Embodiment 3

[0043] Take 60g of collagen stock solution (collagen solid content 1.25%), dissolve in 0.1% acetic acid solution, stir well, and prepare a collagen solution; take 125mg of chitosan (molecular weight 500,000, degree of deacetylation 85%) stirring in the acetic acid solution to prepare a chitosan solution; mixing the collagen solution and the chitosan solution and stirring evenly to prepare a collagen-chitosan solution for later use. Dissolve 200 mg of lecithin in 5.0 ml of DMSO, dissolve 30 mg of mitomycin in 1.0 ml of DMSO, mix the two, and lyophilize to obtain a gel-like mixture. Dissolve 500 mg of PLGA with a molecular weight of 30,000 in a mixture of 10 ml of dichloromethane and acetone (volume ratio 3:1), and add the PLA solution dropwise to the colloidal mixture under stirring conditions to form a uniform reverse micellar solution; The obtained reverse micellar solution was slowly injected into 45 ml of 0.5% PVA solution under the stirring condition of 6000 r / min to prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com