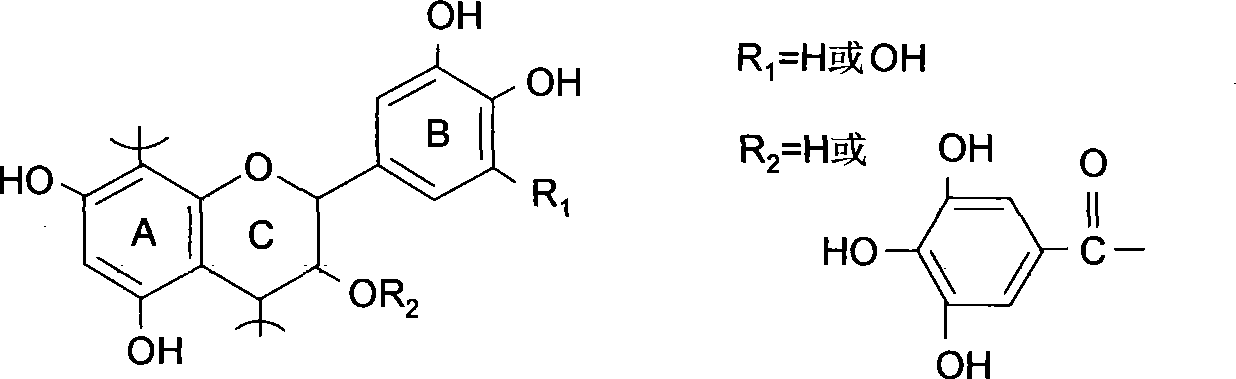

Method of extracting natural oxidationresistant active substanceoil from orange tree bark

A technology of natural antioxidants and active substances, applied in the directions of antitoxins, drug combinations, pharmaceutical formulations, etc., can solve the problems that natural antioxidants have not been reported at home and abroad, and achieve the effect of efficient utilization and rich sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

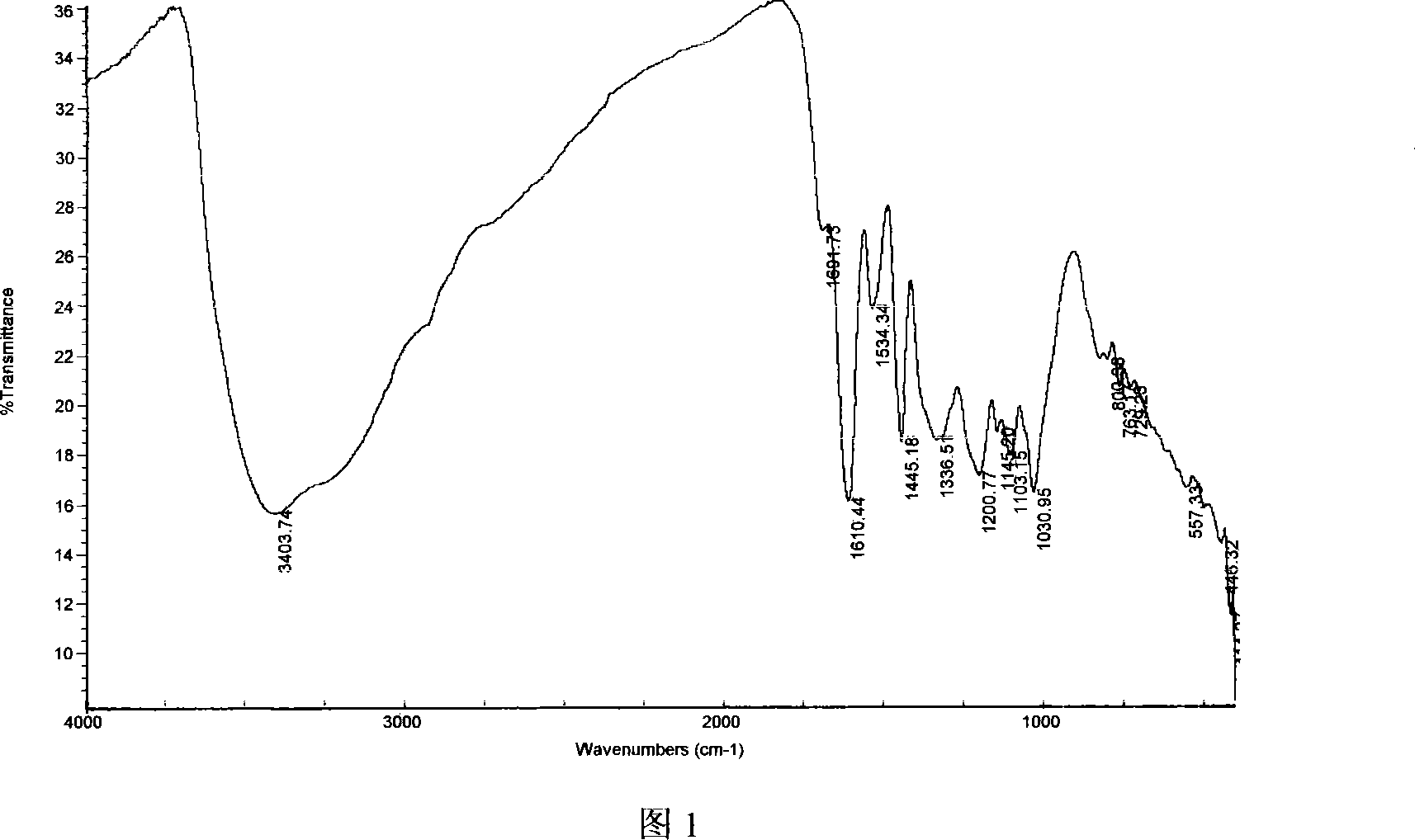

[0028] A method of extracting natural antioxidant active substances from the bark of Amla emblica is:

[0029] (1) pulverizing: the clean emblica bark raw material is pulverized with a plant pulverizer;

[0030] (2) Extraction: use water as solvent, and the solid-liquid mass volume ratio of crushed bark raw material and water is 1: 5~10g / ml, immerse the pulverized bark raw material in water, at 50~80 ℃ Under the action of temperature and ultrasonic waves, extract for 60-120 minutes to obtain the extract. Wherein the solid-liquid mass volume ratio can be any value in 1:5~10g / ml, such as 1:5g / ml, 1:7g / ml, 1:8g / ml, 1:10g / ml, etc., and the temperature can be For any value between 50 and 80°C, such as 50°C, 58°C, 64°C, 75°C, and 80°C, the extraction time can be 60min, 71min, 83min, 96min, 105min, 112min, 120min, etc.

[0031] (3) Flocculation and sedimentation: use chitosan acetic acid solution as flocculant, add chitosan acetic acid solution with a mass concentration of 0.5 to 1...

Embodiment 2

[0038] 1. Put 320g of emblica bark and 2500mL of extraction water after purification, air-drying and crushing (with a plant pulverizer, through a Φ2mm sieve plate) in a KH-200 DB numerically controlled ultrasonic generator tank, under the action of ultrasonic intensification to extract. The ultrasonic frequency is 20kHz, the ultrasonic power is 200W, the temperature is controlled at 65±5°C, and the extraction time is 60min. When the time comes, take it out, filter to remove the slag, and obtain 2180 mL of extract.

[0039] 2. Concentrate the extract to 1100mL, add 15mL of chitosan acetic acid solution with a concentration of 1%, and leave it still after stirring while hot. After cooling to room temperature, it was placed in a refrigerator at 7 °C for 48 h. Separate clear liquid 1050mL, measure its solid content and be 6.5%, total solid content is 71.5g.

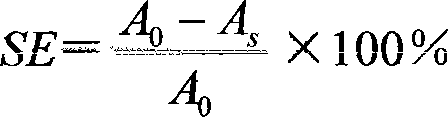

[0040] 3. Add 12g of activated carbon and 0.4g of EDTA-2Na to the clear solution at 80°C, stir for 0.5h, filter to remov...

Embodiment 3

[0045] 1. Place 350g of emblica bark and 2450mL of extraction water pretreated according to the method of Example 1 in a KH-200 DB type numerically controlled ultrasonic generator tank, and extract under ultrasonic strengthening. The ultrasonic frequency is 40kHz, the ultrasonic power is 100W, the temperature is controlled at 70±5°C, and the extraction time is 90min. When the time comes, take it out, filter to remove the slag, and obtain 2100 mL of extract.

[0046] 2. Add 17 mL of chitosan acetic acid solution with a concentration of 1% to the extract, stir vigorously and let it stand to cool to room temperature, put it in a refrigerator at 5°C for 24 hours, and then separate out 2000 mL of the clear liquid.

[0047] 3. Add 14g of activated carbon and 0.4g of EDTA-2Na to the clear liquid at 85°C, stir for 1 hour, filter to remove carbon, and use the filtrate as the upper column liquid for resin adsorption separation.

[0048] 4. Add the clear liquid to the pretreated AB-8 ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com