Fluorescent silicon nitride based nano thread and preparation thereof

A silicon nitride-based and wire silicon nitride-based technology, which is applied in the field of silicon nitride-based nanowires and its preparation, can solve the problems that have not yet been reported on silicon nitride-based nanowires.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Preparation of α-Si by existing technology 3 N 4 Nanowires:

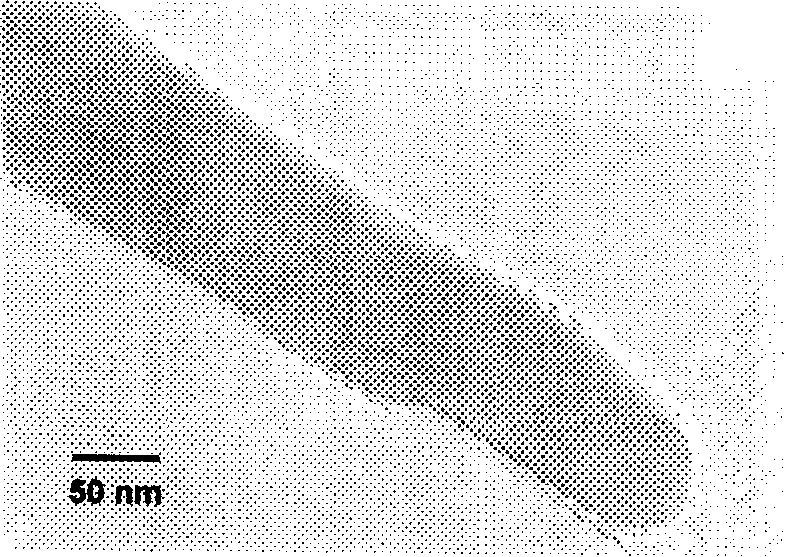

[0025] The specific preparation process is as described in the paper "Synthesis and characterization of siliconcarbide, silicon oxynitride and silicon nitride nanowires" (Journal of Material Chemistry 2002, 12, 1606-1611) in the "Material Chemistry" magazine, that is, by heating the mixture of silica gel and simple silicon, Gas-phase SiO is generated, and α-Si is obtained by gas-solid growth in flowing ammonia at 1350 °C 3 N 4 Nanowires, the length and diameter of nanowires can be controlled by controlling airflow, temperature, etc., so that the diameter is about 100-200 nanometers and the length is 100-300 microns;

[0026] (2) Dissolve 0.5 millimoles of europium oxide in 10 milliliters of nitric acid solution with a concentration of 0.4 mol / liter, heat to 60 degrees, and after completely dissolving, evaporate to dryness at 100 degrees to obtain rare earth nitrate Eu(NO 3 ) 3 ;

[0027] (3) The pre...

Embodiment 2

[0033] (1) Preparation of α-Si by existing technology 3 N 4 0.01 moles (1.4 grams) of nanowires are used to make the diameter about 300-400 nanometers and the length 500-800 microns. The specific preparation process is the same as in Example 1.

[0034] (2) Dissolve 0.5 millimoles of dysprosium oxide in 10 milliliters of nitric acid solution with a concentration of 0.4 mol / liter, heat to 60 degrees, after completely dissolving, evaporate to dryness at 100 degrees to obtain rare earth nitrate Dy(NO 3 ) 3 :

[0035] (3) 0.01 mol (1.4 g) α-Si 3 N 4 nanowires with 0.1 mmol (0.0348 g) of Dy(NO 3 ) 3 Mix and dissolve in 10 ml of methanol / water (volume ratio 1:1) solution, and disperse by ultrasonic (power 400W, frequency 40KHZ) for 20 minutes;

[0036] (4) Then transfer the mixed slurry to a rotary vacuum dryer for drying at 60° C. for 20 minutes.

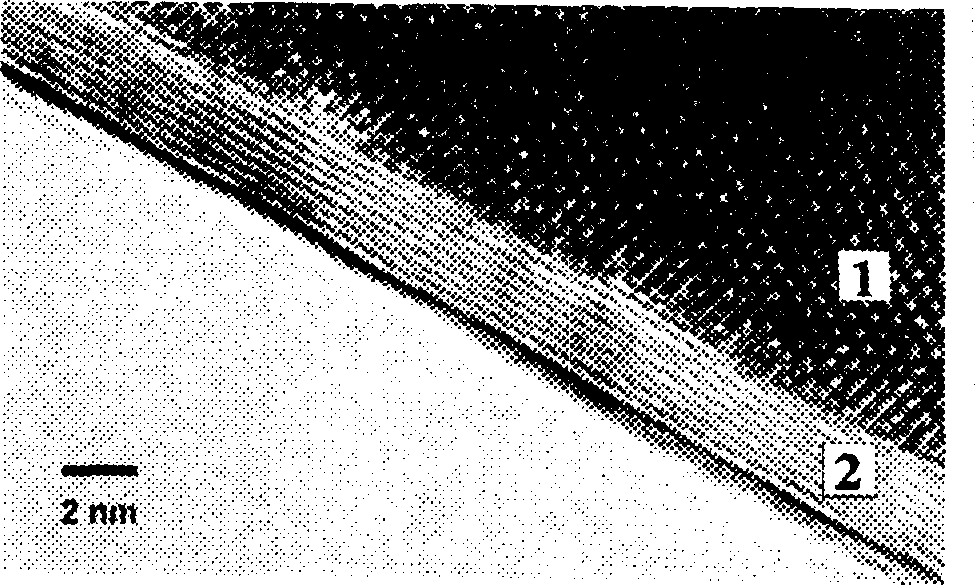

[0037] (5) Transfer to a BN crucible after drying, and add about 0.028 grams of B in advance at the bottom 2 o 3 powder. Rai...

Embodiment 3

[0040] Concrete preparation process is the same as embodiment 2, but does not add B in step (5) 2 o 3 powder to obtain a nanowire with a Dy metal ion solid solution as the luminescent center; the nanowire also emits blue light and yellow light with a maximum luminous wavelength of 482nm and 578nm under ultraviolet light (shown as emitting white light), and the excitation and emission spectra are the same as Figure 7 Similar, compared with the situation of the boron nitride thin film protective layer in embodiment 2, its intensity has decreased by 40%, but compared with the nanowires without metal ion solid solution as the luminescent center in the prior art, its intensity still increases More than 5 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com