Method for preparing carbon nano-tube by catalyzing and carbonizing polymer and /or asphalt

A technology of carbon nanotubes and catalytic carbonization, which is applied in the direction of nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of complex preparation process, etc., and achieve the effect of easy mixing, simplified preparation process and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] First prepare α-zirconium phosphate, then use methylamine to perform interlayer pre-support, and then use hexadecyltrimethylammonium bromide to further intercalate it to obtain organically modified zirconium phosphate; according to the mass ratio of 3 : 97 Weigh organically modified zirconium phosphate and styrene-butadiene-acrylonitrile copolymer, first place styrene-butadiene-acrylonitrile copolymer in the internal mixer, heat to molten state and start stirring, then add Organically modified zirconium phosphate, continue mixing and stirring for 10 minutes, stop stirring, and take out the composite material formed by the copolymer and organically modified zirconium phosphate.

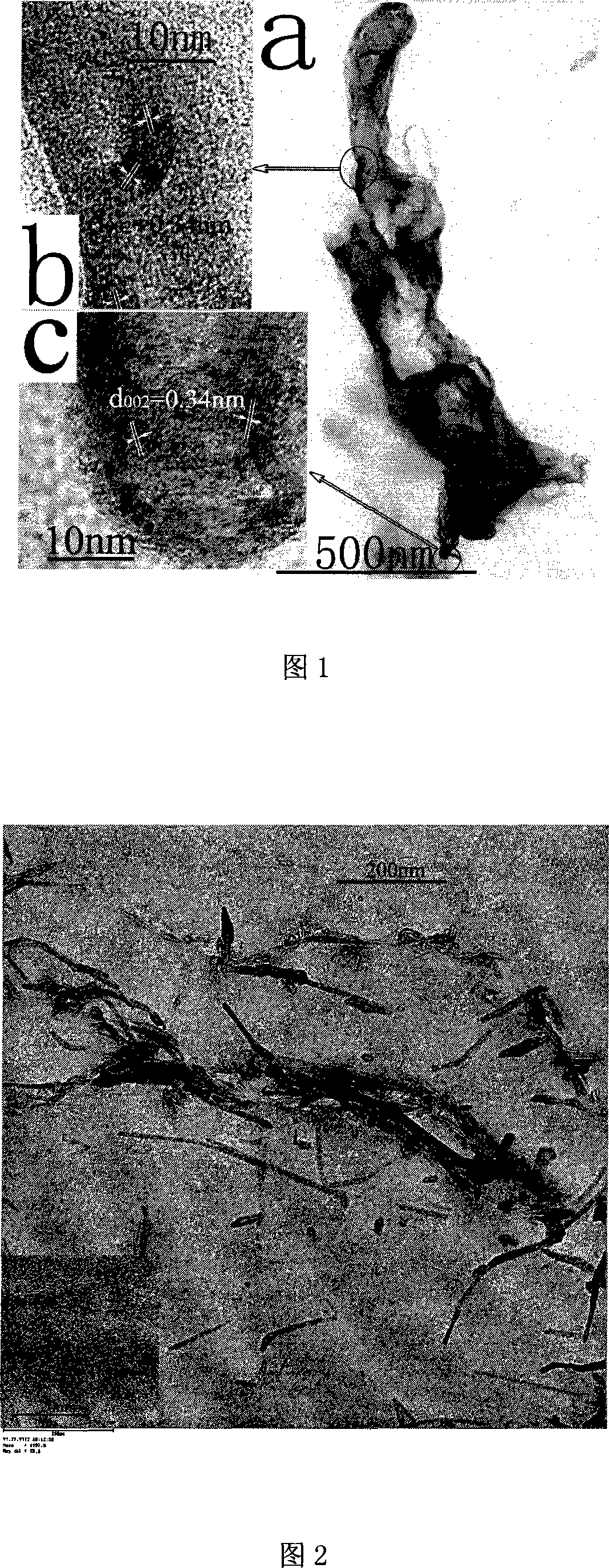

[0021] The composite material formed by the copolymer and organically modified zirconium phosphate is placed in the constant temperature zone of the reaction chamber of a muffle furnace at 360°C, and reacted under air conditions for 1 hour to obtain the product. Fig. 1 has provided the high-reso...

Embodiment 2

[0024] First prepare α-zirconium phosphate, then use ethylamine to carry out interlayer pre-support, and then use octadecyltrimethylammonium chloride to further intercalate it to obtain organically modified zirconium phosphate; according to the mass ratio of 3 : 97 take organically modified zirconium phosphate and butadiene-styrene copolymer; butadiene-styrene copolymer is placed in the internal mixer, heated to molten state and start stirring, then add organically modified zirconium phosphate, continue Mix and stir for 10 minutes, stop stirring, and take out the composite material formed by the butadiene-styrene copolymer and the organically modified zirconium phosphate.

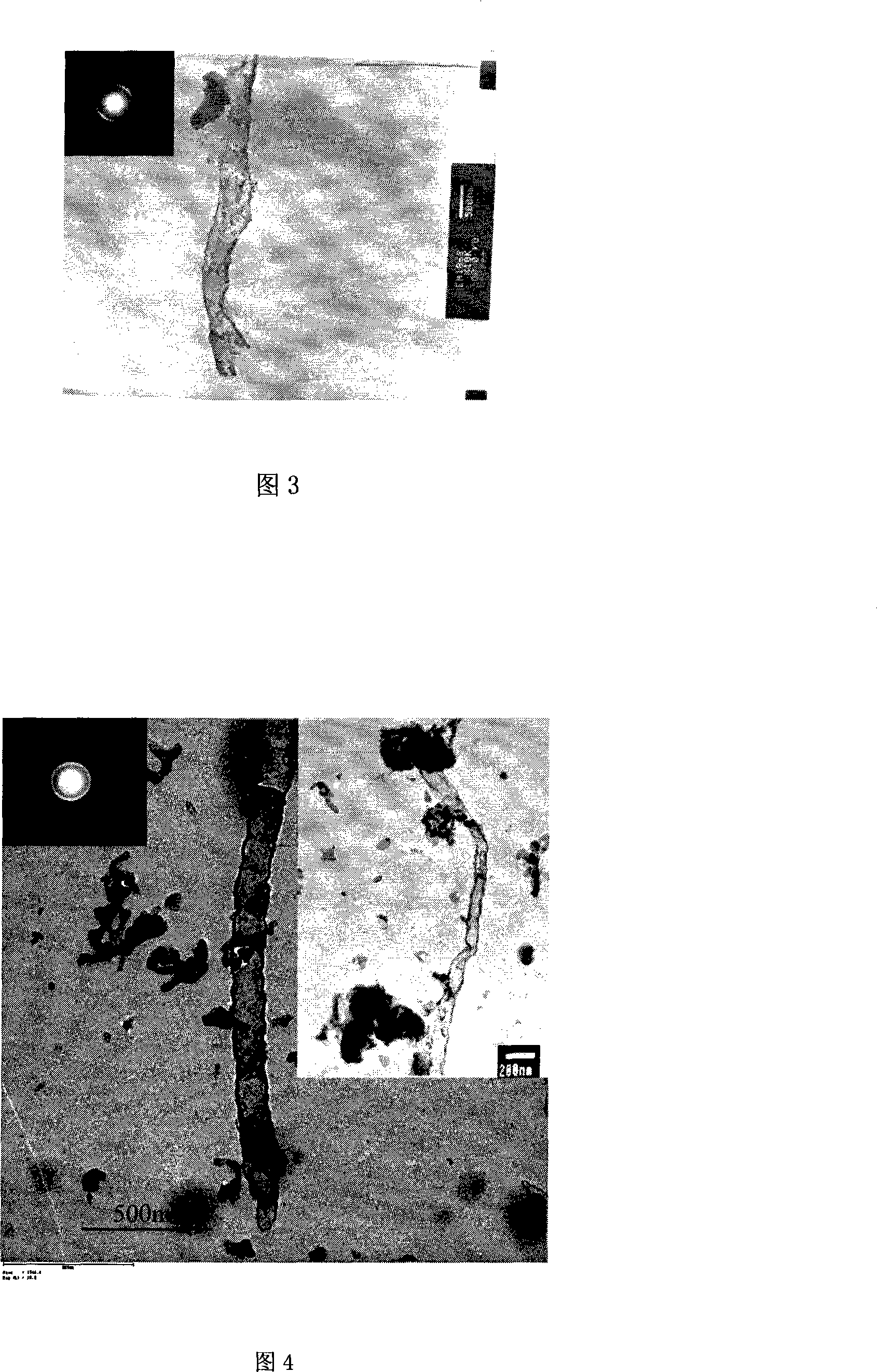

[0025] Put the composite material in the constant temperature zone of the reaction chamber of the muffle furnace at 800°C, and react under air conditions for 1 hour to obtain carbon nanotubes with a length of 200nm-6μm and a diameter of 50-200nm. The degree of chemical transformation is high, and there are ...

Embodiment 3

[0027] First prepare α-zirconium phosphate, then use ethylamine to carry out interlayer pre-support, and then use tetradecyl dimethyl benzyl ammonium chloride to further intercalate it to obtain organically modified zirconium phosphate; Weigh organically modified zirconium phosphate and butadiene-styrene copolymer at a ratio of 5:95; dissolve the butadiene-styrene copolymer in toluene and place it in a stainless steel reactor lined with polytetrafluoroethylene, and then add Organically modified zirconium phosphate powder, after stirring evenly, put it into an oven and react at 150°C for 3h; then take out the product and dry it at 80°C for 24h, remove the solvent toluene, and obtain the butadiene-styrene copolymer and organically modified zirconium phosphate. composite material.

[0028] The composite material is placed in the constant temperature zone of the reaction chamber of a muffle furnace at 600°C, and reacted under air conditions for 30 minutes to obtain the product.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com