Process for preparing titanium dioxide of hollow sphere structure

A technology of titanium dioxide and hollow spheres, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of limited development, complex post-processing technology, poor crystallinity, etc., and achieve simple equipment and process, wide application prospects, and good crystallinity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

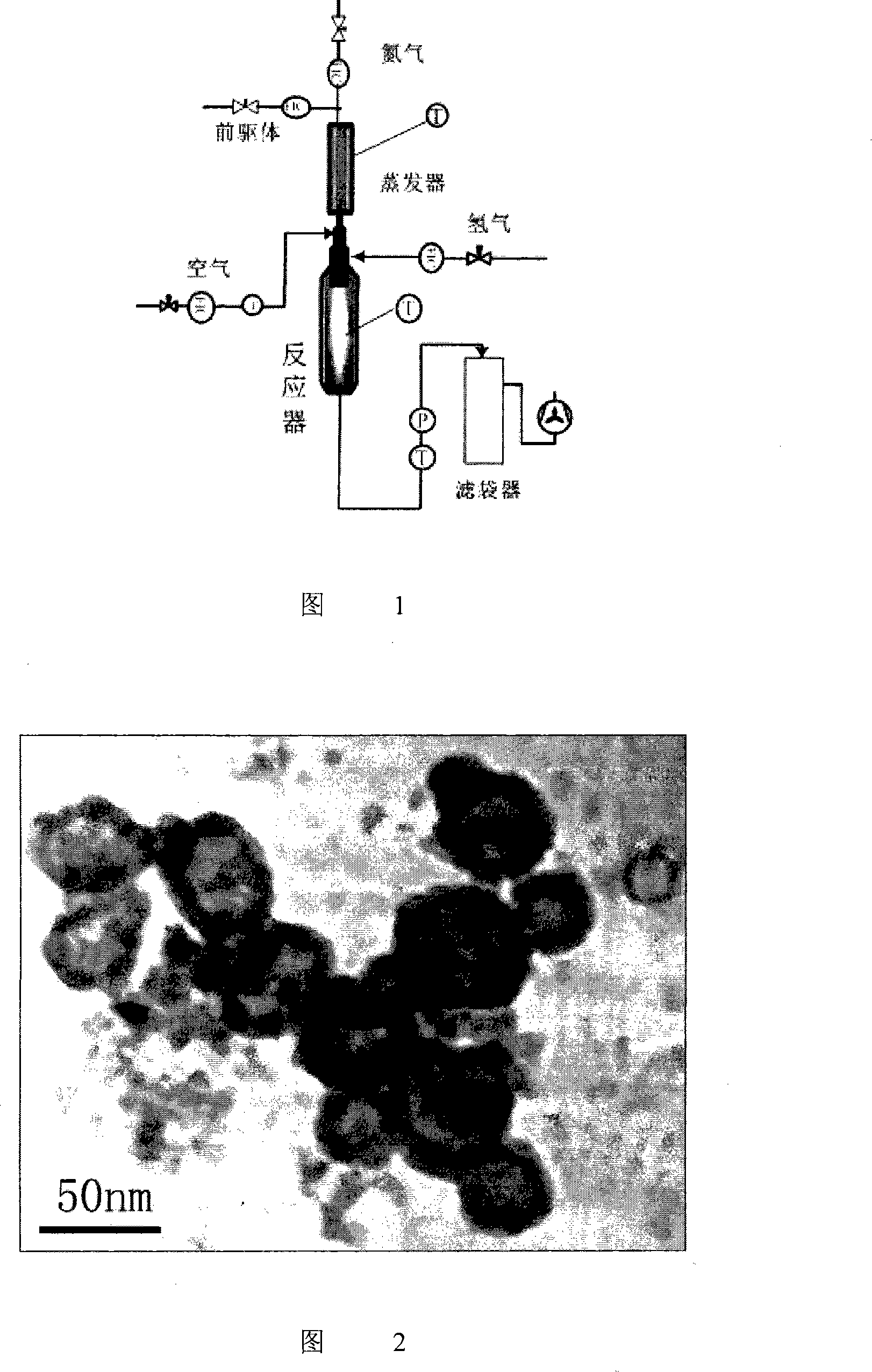

Method used

Image

Examples

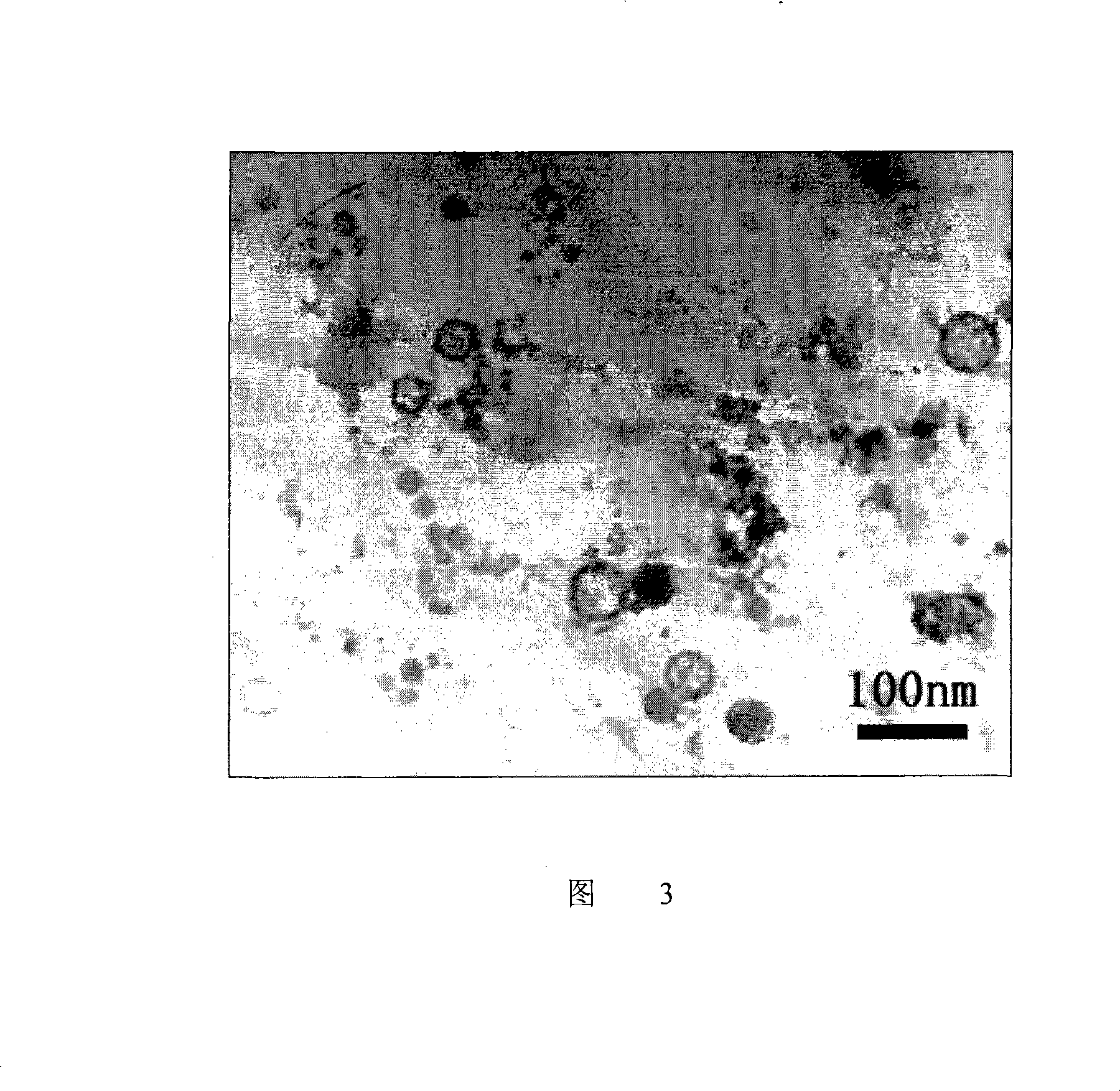

Embodiment 1

[0020] TiCl 4 and triton in absolute ethanol (TiCl 4 Mass fraction is 18%, triton 6g, feed rate is 10ml / min), magnetic stirring 100min, is loaded into evaporator by nitrogen, nitrogen flow rate is 1.8m 3 / h, the temperature of the evaporator is controlled at 270°C, and after vaporization, it enters the combustion reactor through the central tube of the burner. Second ring air (2.0m 3 / h) and tricyclic hydrogen (0.2m 3 / h) form an auxiliary combustion flame, the hydrolysis reaction of the precursor is carried out in the combustion chamber, control the temperature of the gas at the outlet of the burner within the range of 120 ° C, so that the precursor condenses to form atomized steam, enters the combustion chamber and burns to undergo a hydrolysis reaction, and on the surface Under the action of an active agent, self-assembly occurs to form a nano-titanium dioxide hollow sphere structure, and the reaction temperature is 1800°C. The average particle size of the prepared nano-...

Embodiment 2

[0022] TiCl 4 and triton in absolute ethanol (TiCl 4 Mass fraction is 18%, triton 12g, feed rate is 9ml / min), magnetic stirring 30min, is loaded into evaporator by N2, nitrogen flow rate is 0.7m 3 / h, the temperature of the evaporator is controlled at 250°C, and after vaporization, it enters the combustion reactor through the central tube of the burner. Second ring air (3.0m 3 / h) and tricyclic hydrogen (0.2m 3 / h) form an auxiliary combustion flame, the hydrolysis reaction of the precursor is carried out in the combustion chamber, and the temperature of the gas at the outlet of the burner is controlled within the range of 100°C, so that the precursor is condensed to form atomized steam, which enters the combustion chamber and burns to undergo a hydrolysis reaction, and on the surface Under the action of an active agent, self-assembly occurs to form a nano-titanium dioxide hollow sphere structure. The reaction temperature is 1500°C. The average size of the prepared nano-tit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com