Carbon content controllable silicon-containing ceramic and preparing method thereof

A technology of carbon content and ceramics, which is applied in the field of silicon-containing ceramics with controllable carbon content and the preparation field, can solve the problem of ineffective formation of excess carbon, achieve the effects of increasing density, eliminating free carbon, and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

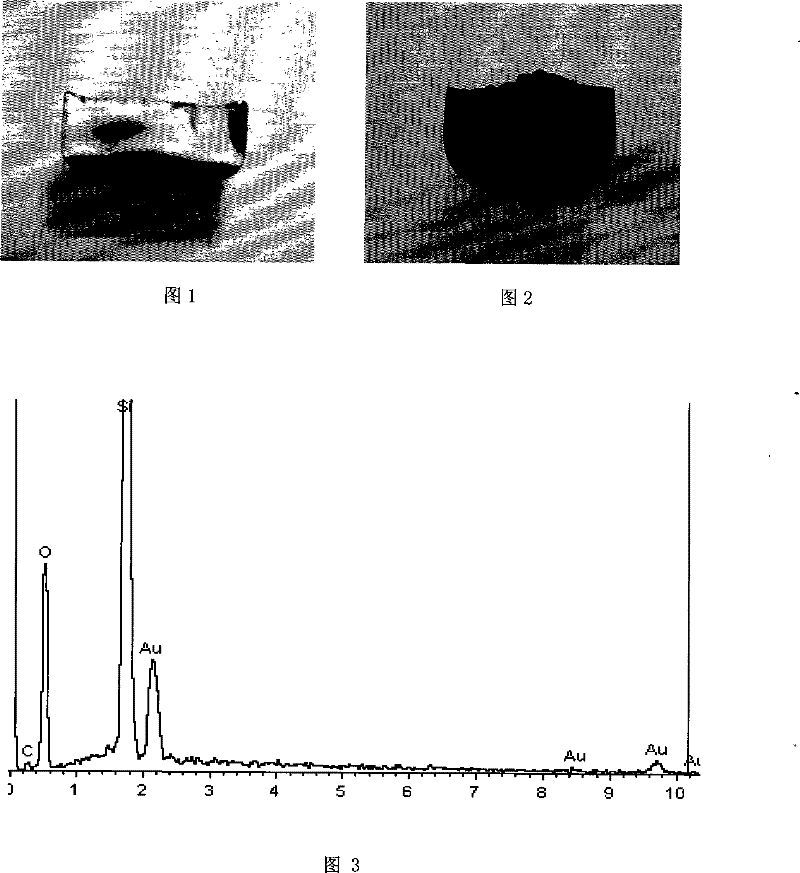

[0018] Using 5g of polymethylhydrogensiloxane (viscosity: 15-50mPa.s, 20°C) and 5g of vinylsiloxane as precursors, adding 1wt% of vinylsiloxane platinum complex catalyst, adding 5g of polydimethylsiloxane Methyl siloxane is mixed and stirred evenly, thermally cross-linked at 80°C, put into a tube furnace, flow argon, flow rate 150sccm, flow water vapor, partial pressure 0.2atm, heat to 1000°C, smooth and crack-free The white ceramics, the productive rate is 71wt%, energy spectrum (Fig. 3) analysis carbon content 3.86wt.%. Optical photos such as figure 1 .

Embodiment 2

[0020] A mixture of polymethylhydrogensiloxane, vinylsiloxane (mass ratio 1:1) and polydimethylsilane was used as the precursor. After thermal crosslinking, it was placed in a tube furnace, and argon was introduced at a flow rate of 150 sccm, heated to 1000°C, a black ceramic was obtained with a yield of 61wt%, and a carbon content of 34wt.% according to energy spectrum analysis. Optical photos are shown in Figure 2.

Embodiment 3

[0022] Using polycarbosilane (molecular weight: 2000) as the precursor, oxidizing and cross-linking it at 180°C, then hot-pressing it, putting it into a tube furnace, feeding argon gas at a flow rate of 150 sccm, feeding water vapor, and a partial pressure ratio of 0.2 atm. Heating to 1000°C, a white ceramic was obtained, and the carbon content was 7.6wt.% according to energy spectrum analysis.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com