Over-branched polyamidoamine and metal nano compound as well as preparation method and uses thereof

A technology of polyamidoamine and metal nanometers, which is applied in the field of hyperbranched polyamidoamine and metal nanocomposites and its preparation to achieve excellent antibacterial effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Add 6.164g N, N-methylenebisacrylamide (40mmol) and 2.584g 1-(2-aminoethyl) piperazine (20mmol) into a mixed solvent of 40mL methanol and 20mL deionized water, under nitrogen protection , polymerized at 50°C for 150 hours, cooled at room temperature, added 10mL of dimethylamine aqueous solution (33wt%), continued the reaction at 50°C for 48 hours, concentrated the product by rotary evaporation, washed with acetone precipitation, and dried in vacuo at 50°C to obtain two Methylamine-terminated hyperbranched polyamidoamines. Yield 91%.

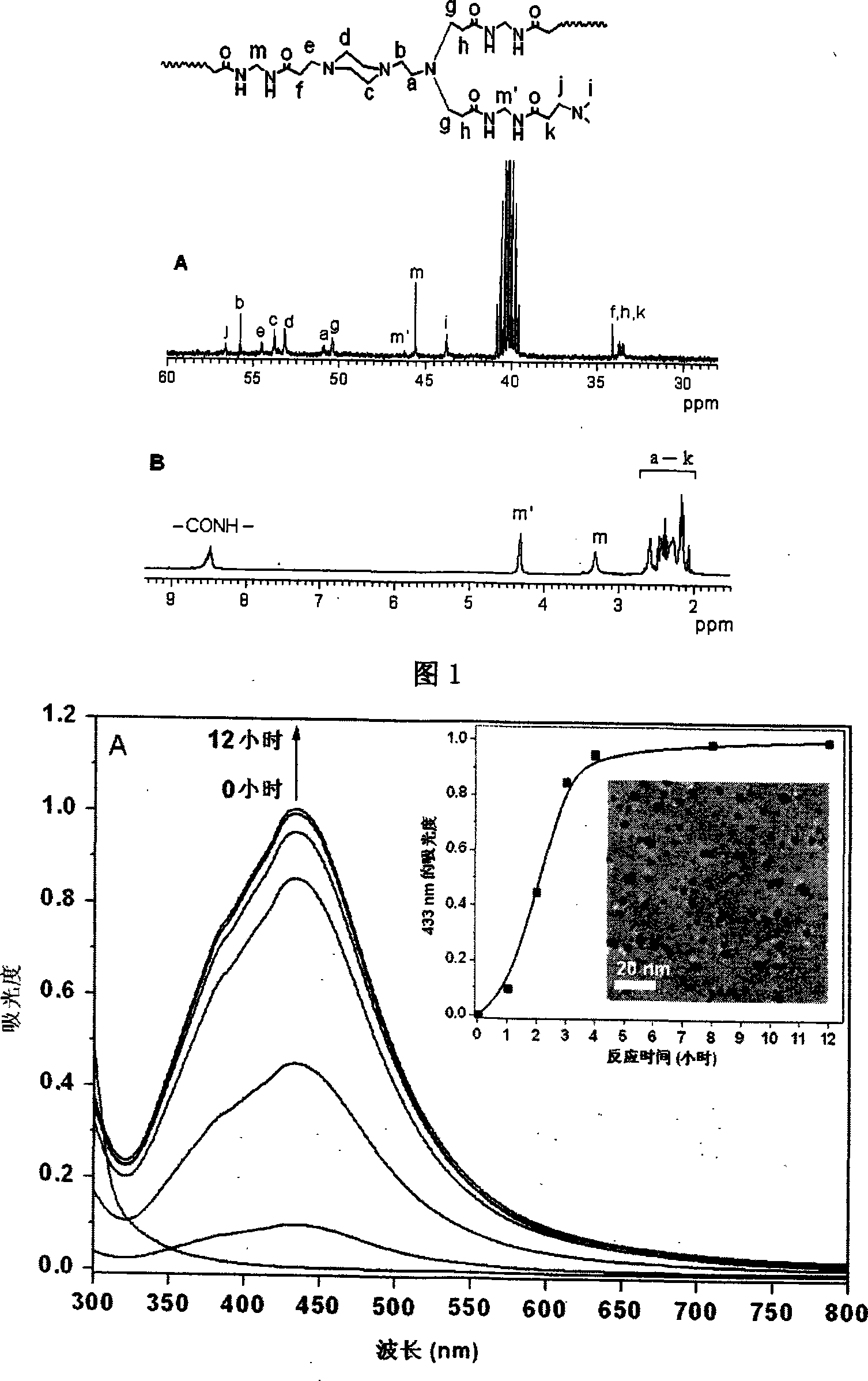

[0037] The total amine value of the hyperbranched polyamidoamine of gained dimethylamine end-capping is 0.17mol / g, and weight-average molecular weight is 1.4 * 10 5 g / mol, the radius of rotation is 14.04nm, and the hydrodynamic radius is 13.01nm. The ratio of the radius of rotation to the hydrodynamic radius is 1.08, which is close to 1.0, indicating that the polymer has a highly branched molecular structure. Accompanying drawing 1 is t...

Embodiment 2

[0040] 0.2g of the hyperbranched polyamidoamine in Example 1 was made into a 5wt% aqueous solution, and 0.1mol / L silver nitrate aqueous solution was added dropwise according to N / Ag=15, or 0.05mol was added dropwise according to N / Au=15 / L of chloroauric acid aqueous solution. Then the mixed solution was reacted at room temperature for 12 hours to obtain a stable nano-silver or nano-gold aqueous dispersion. Concentrate by rotary evaporation, precipitate with acetone, and dry in vacuum to obtain powdered brown-yellow polyamidoamine / silver nanocomposite or pink polyamidoamine / gold nanocomposite.

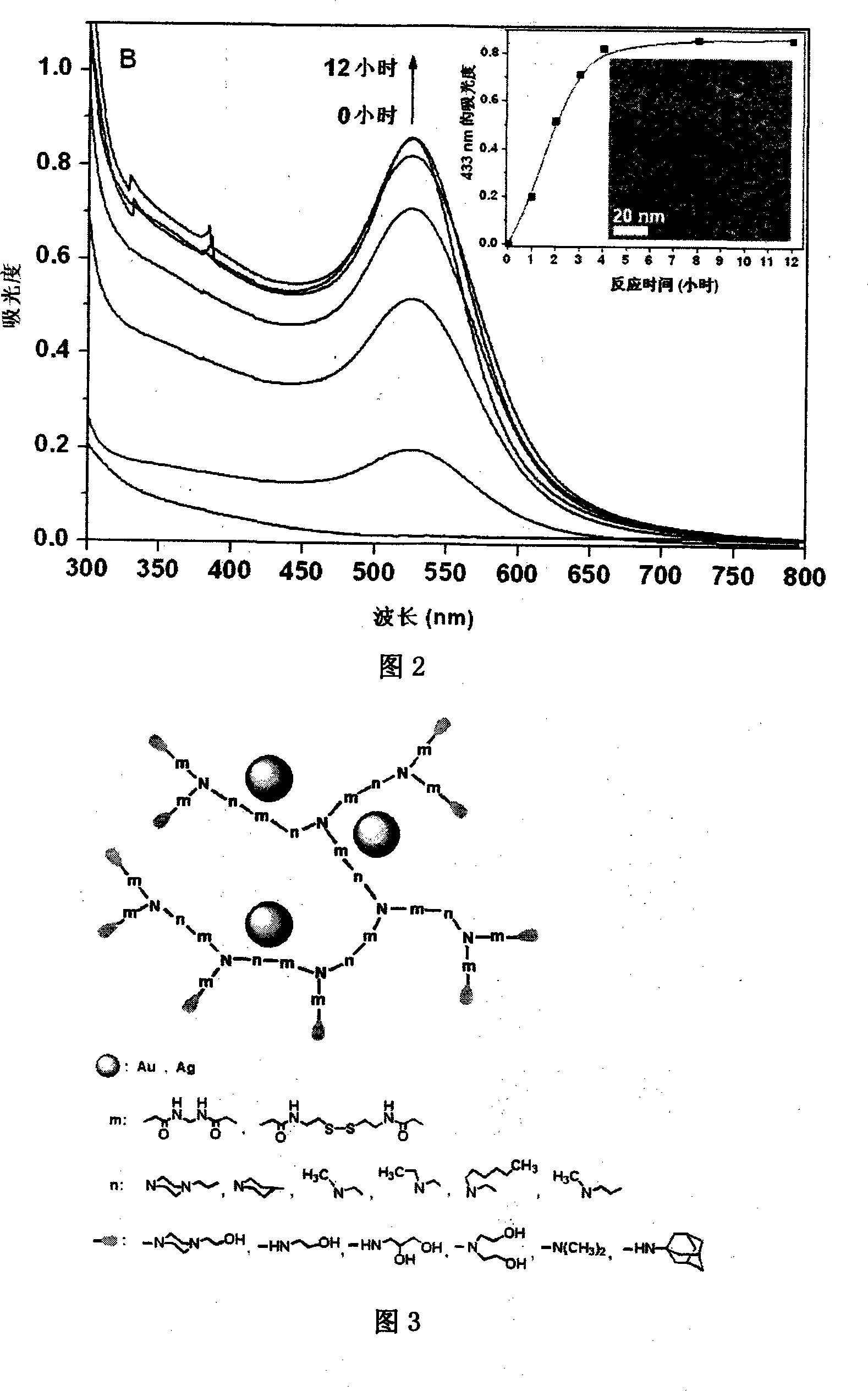

[0041] During the above reaction process, the generation of metal nanoparticles was tracked by using ultraviolet-visible light absorption spectrum, and its morphology was observed by transmission electron microscope. The results are shown in Figure 2. As can be seen from accompanying drawing 2 (A), along with the carrying out of reaction, the ultraviolet absorption peak at 433nm place...

Embodiment 3

[0043] Change N / Ag or N / Au feed molar ratio, under the condition of N / Ag or N / Au=10,20,30, according to the operating method of embodiment 2, the hyperbranched polyamidoamine in embodiment 1 The aqueous solution (10wt%) reacts with corresponding different amounts of silver nitrate or chloroauric acid to obtain metal nanoparticle aqueous dispersions with different particle sizes, which can be stored stably for more than half a year at normal temperature.

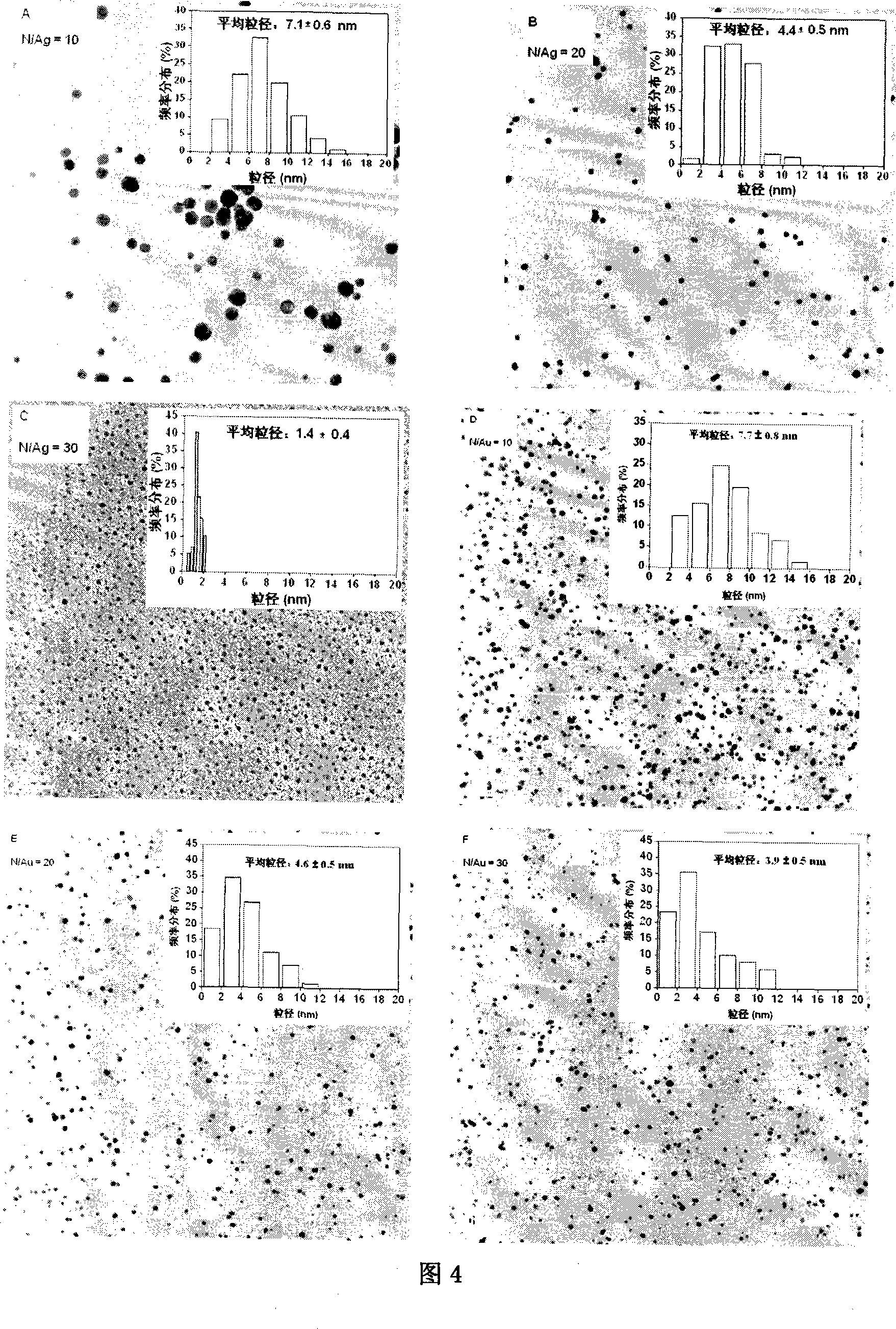

[0044] In the obtained hyperbranched polyamidoamine and metal nanocomposite, the weight percent content of the polymer is: 89%-98%; the metal nanoparticle component is gold or silver nanoparticles, and the metal weight percent content is: 2%-11%, A schematic diagram of its molecular structure is shown in Figure 3. In addition, the morphology of the prepared metal nanoparticles was measured by transmission electron microscopy, and the results are shown in Fig. 4 . Accompanying drawing 4 (A)-(C) is the transmission electron mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com