Method of using ammonia process to remove carbon dioxide from generating plant smoke gas and system thereof

A carbon dioxide and flue gas technology, applied in chemical instruments and methods, separation methods, air quality improvement, etc., can solve problems such as difficult to effectively remove carbon dioxide, overcome inherent defects, reduce investment and operating costs, and increase contact area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

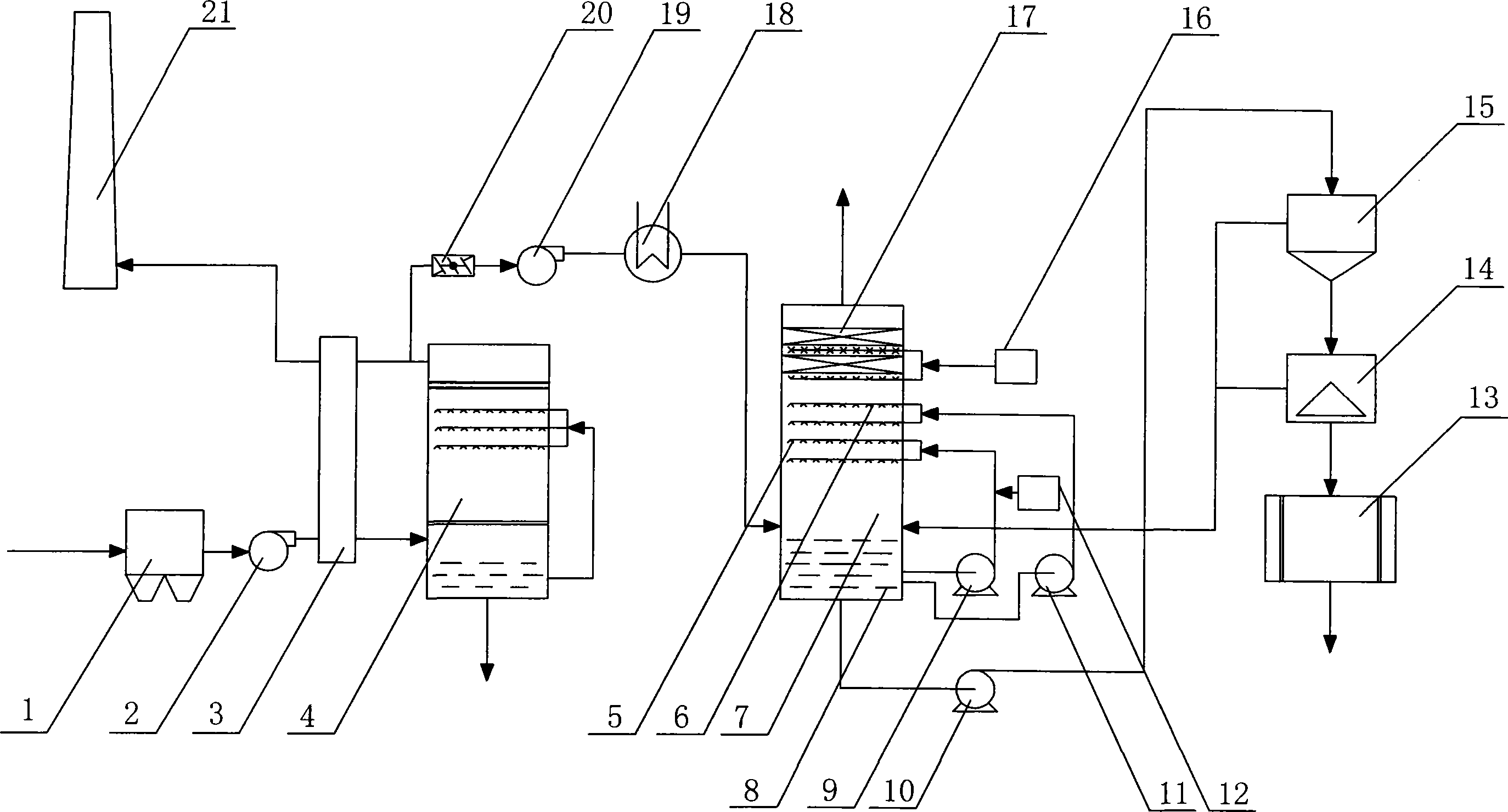

[0026] Below for the flue gas discharged by a power station boiler unit, the present invention will be further described in detail in conjunction with the accompanying drawings:

[0027] The traditional flue gas desulfurization system shown in the figure uses limestone absorbent for desulfurization, which includes an electric precipitator 1, and the smoke outlet of the electric precipitator 1 passes through the inlet of the booster fan 2, the flue gas heat exchanger 3 and the desulfurization reaction tower 4 in sequence. The smoke outlets are connected, and the smoke outlet of the desulfurization reaction tower 4 is divided into two paths, one path is directly connected to the chimney 21 through the flue gas heat exchanger 3, and the other path is sequentially passed through the flue gas bypass baffle plate 20, the pressurizing fan 19, and the cooler 18 is connected with the lower flue gas inlet of carbon dioxide absorption tower 7.

[0028] The system for removing carbon diox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com