Method for preparing gallium nitride nano-wire array by using dry etching

A nanowire array, dry etching technology, applied in nanotechnology, nanotechnology, nanostructure manufacturing and other directions, to achieve the effect of high aspect ratio, low preparation requirements, and simple electrochemical corrosion process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

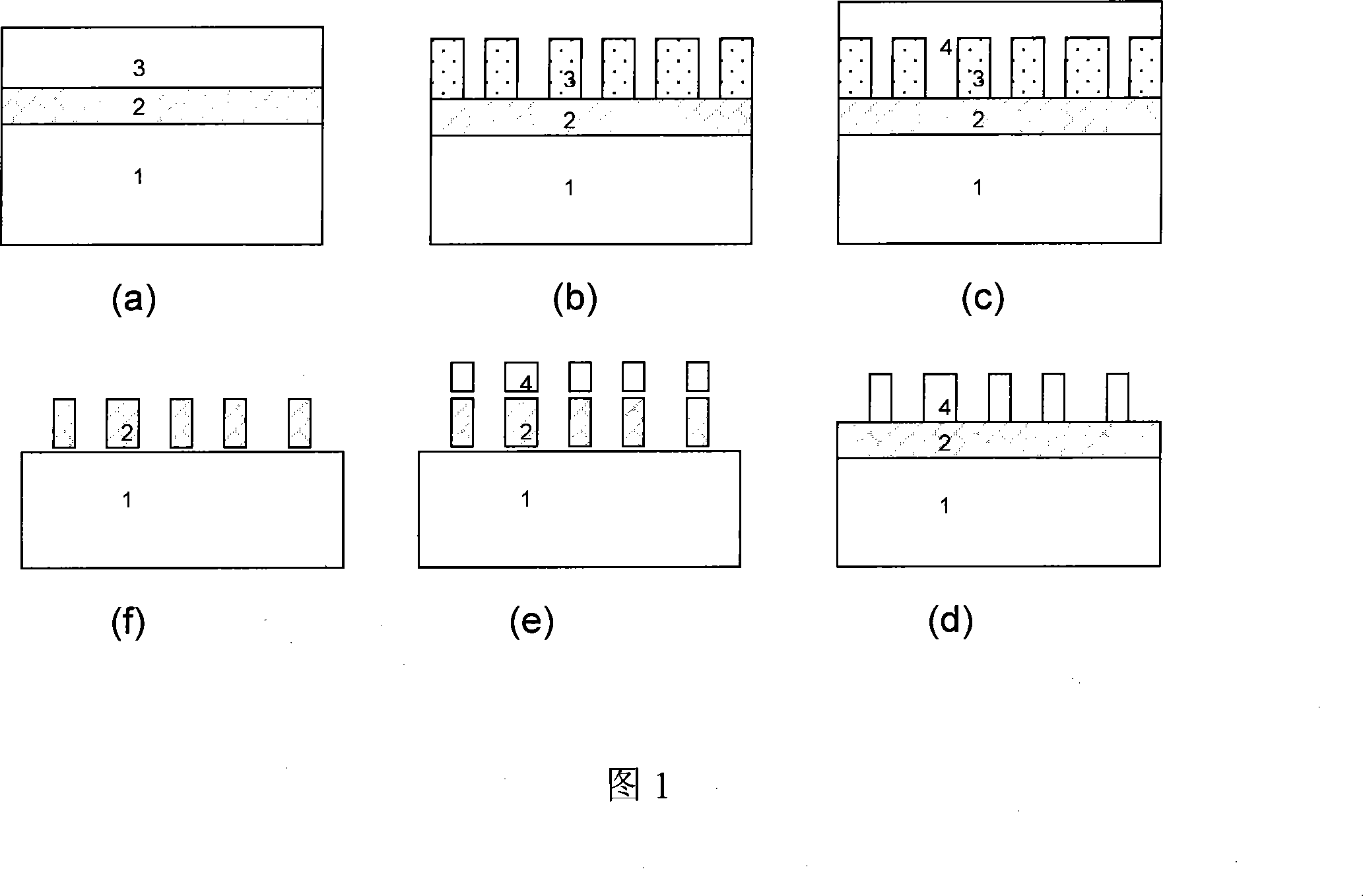

[0024] Using any one of MOCVD, HVPE or MBE methods on Al 2 o 3 4μm GaN is grown on the substrate as a template, and then a 700nm thick metal Al thin layer is deposited on the template by electron beam evaporation at a temperature of 300°C (Figure 1a), and then the template with the metal layer is placed in oxalic acid Solution (3mol / L), anodized at room temperature with a voltage of 40 volts for about 20 minutes, and then put the template into phosphoric acid solution (5wt%) and soaked for 30 minutes to remove the part of the aluminum oxide at the bottom of the hole and in contact with the lower layer of GaN , which also made a mask for depositing metallic Ni nanoparticle lattices (Fig. 1b). Next, 20 nm of Ni metal was evaporated on the template using an electron beam (Fig. 1c). Since electron beam evaporation is not selective, after removing the anodic aluminum oxide with alkaline solution (0.2mol / L NaOH solution), a lattice of metallic Ni nanoparticles will be obtained on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com