Cathode for lithium ion secondary battery and lithium ion secondary battery

A secondary battery, lithium ion technology, used in secondary batteries, secondary battery parts, battery electrodes, etc., can solve the problems of not yet reached the negative electrode active material layer, negative electrode active material constraints, no records, etc., to achieve charge and discharge. The effect of excellent cycle characteristics, high output power, high battery capacity and energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

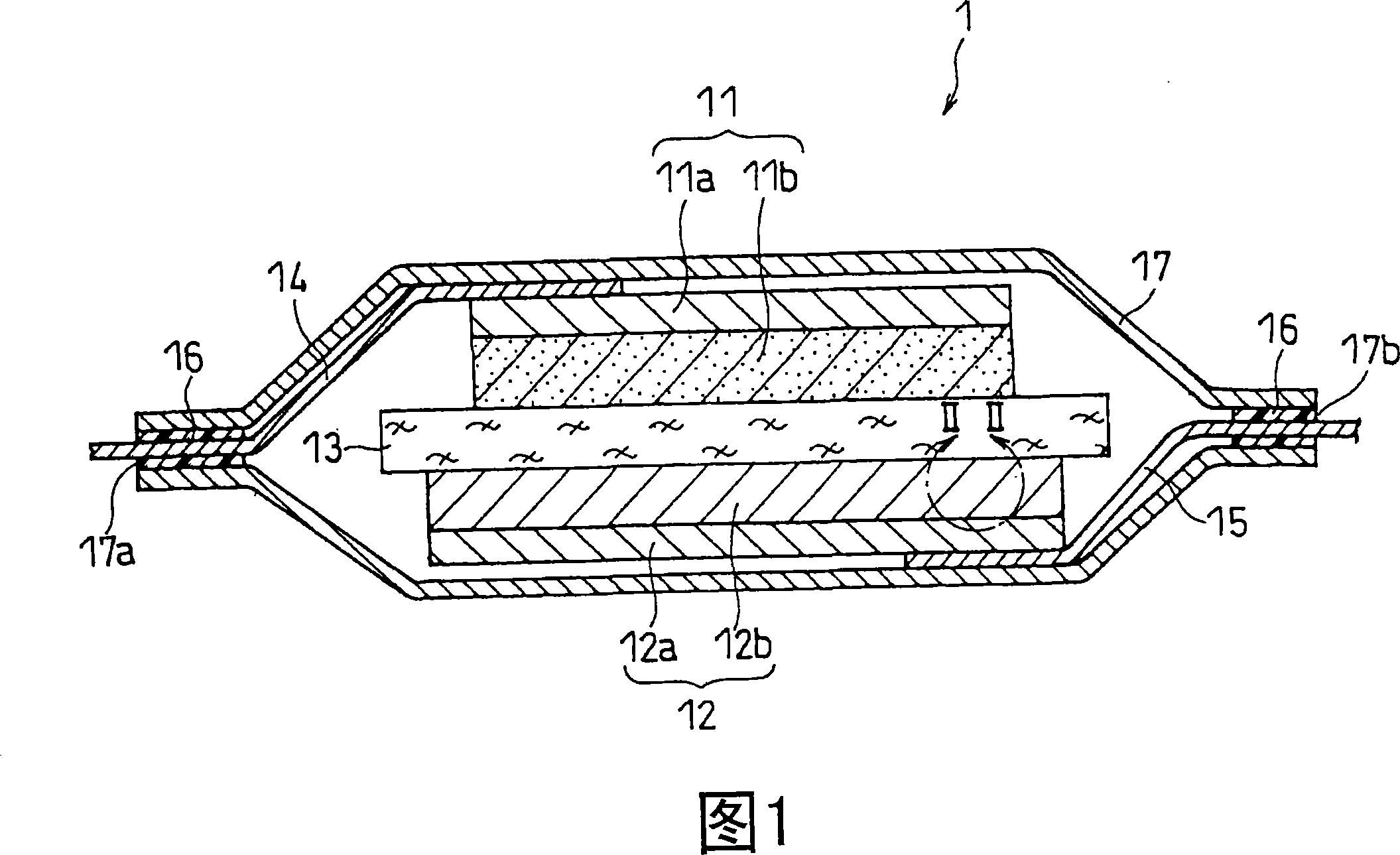

[0080] A lithium ion secondary battery having the same structure as lithium ion secondary battery 1 shown in FIG. 1 was produced by the following method.

[0081] (1) Production of positive electrode

[0082] 10g of lithium cobalt oxide (LiCoO 2 , positive electrode active material) powder, 0.3g acetylene black (conductive agent), 0.8g polyvinylidene fluoride powder (binder) and 5ml N-methyl-2-pyrrolidone (NMP) are fully mixed to prepare the positive electrode Mixture slurry. This positive electrode mixture slurry was coated on one side of an aluminum foil (positive electrode current collector) having a thickness of 20 μm, dried, and then rolled to form a positive electrode active material layer. Thereafter, the positive electrode was cut into a square shape with a side of 30 mm. In the obtained positive electrode, the positive electrode active material layer carried on one side of the aluminum foil had a thickness of 70 μm and a size of 30 mm×30 mm. A positive electrode l...

Embodiment 2

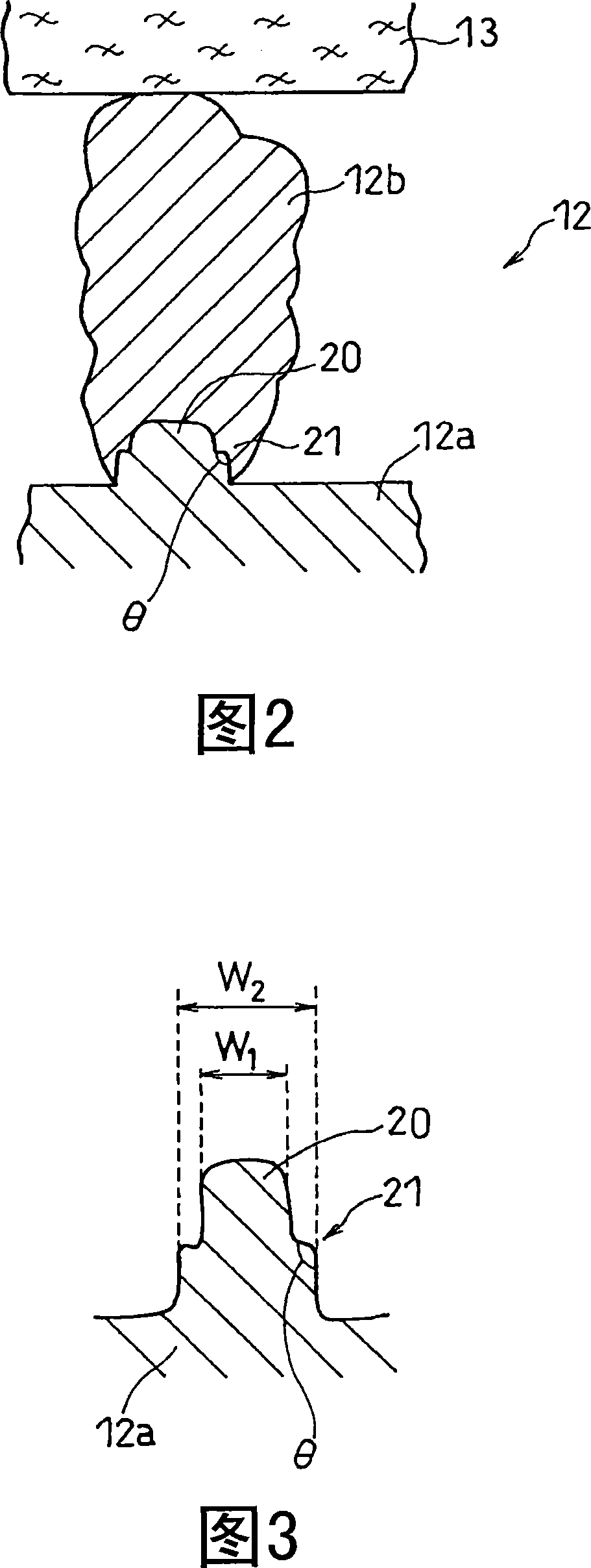

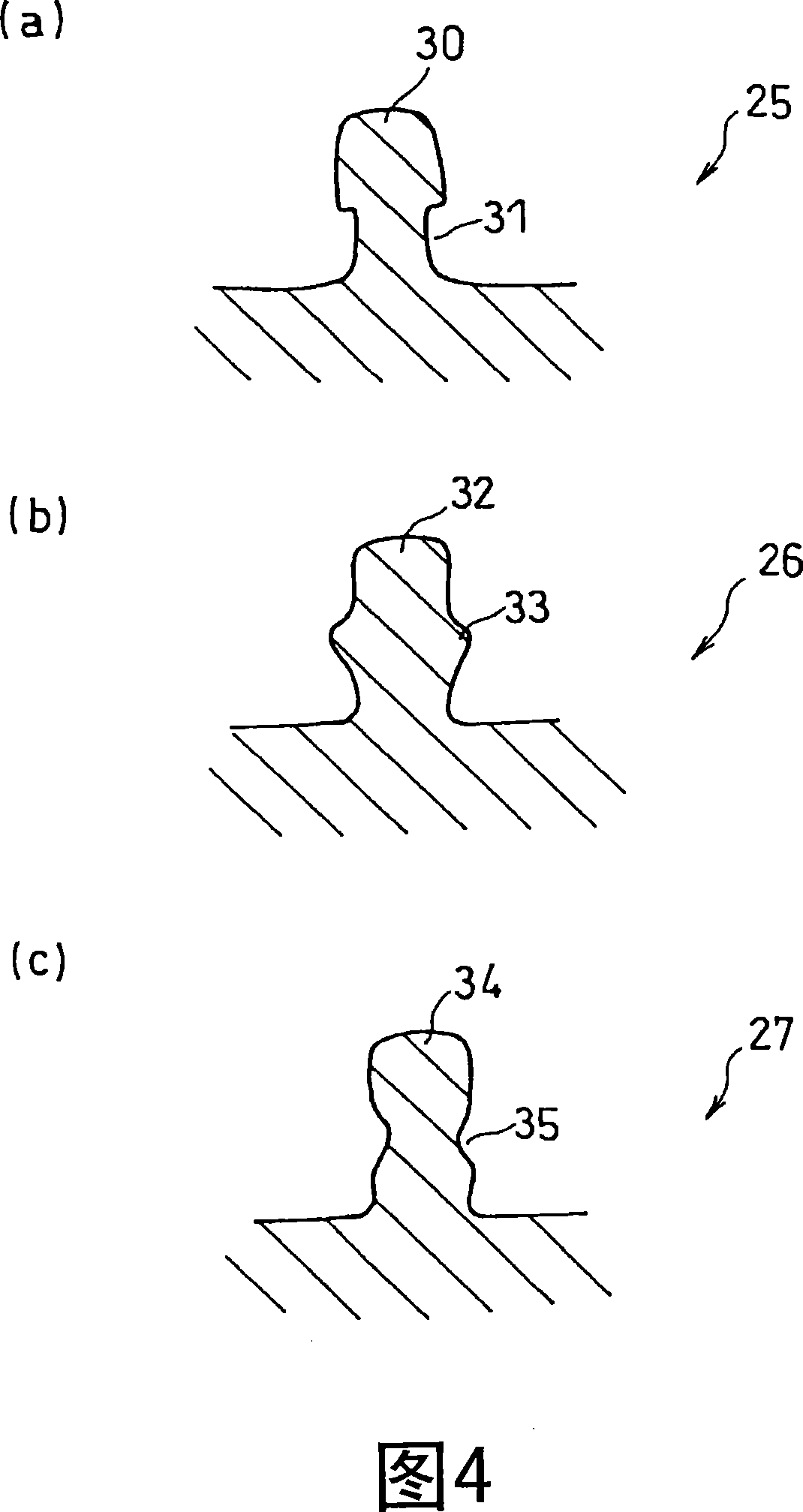

[0116] Except having changed the roll for convex part formation into the following roll for convex part formation, it carried out similarly to Example 1. First, as in Example 1, a ceramic layer made of chromium oxide was formed on the surface of an iron roll. Then, a circular concave portion with a diameter of 12 μm and a depth of 3 μm, that is, a first hole, was formed on the surface of the ceramic layer by laser processing. The 1st hole was designed as the closest packing configuration with a distance between axes of 20 μm. In addition, the bottom of the first hole was processed to have the same shape as that of the bottom of the first hole in Example 1, and the length from the surface of the ceramic layer to the center of the bottom of the first hole was 3 μm. Next, a second hole, which is a circular recess with a diameter of 8 μm and a depth of 3 μm, was formed at the bottom of the first hole so that the axis thereof coincided with that of the first hole. The second hole...

Embodiment 3

[0119] A lithium ion secondary battery of the present invention was produced in the same manner as in Example 1 except that the negative electrode current collector was changed to the following negative electrode current collector.

[0120] On the surface of alloy copper foil (trade name: HCL-02Z, manufactured by Hitachi Electric Cable Co., Ltd.), a dry film photoresist (trade name: PHOTE RY-3300, manufactured by Hitachi Chemical Co., Ltd.) with a thickness of 6 μm was attached . In addition, small circular dots with a diameter of 8 μm were printed on the resin mask. The circular dots were set as the most closely packed configuration with a center-to-center distance of 20 μm. This resin mask was placed on a dry film photoresist, exposed to i-rays using a collimated light aligner, and then developed in an aqueous solution of sodium carbonate at a concentration of 1% by weight to form a photoresist. picture of. Next, copper protrusions are formed in the openings of the photor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com