Tin silver gold leadless welding material and preparation thereof

A lead-free soldering and raw material technology, applied in the direction of welding/cutting medium/material, welding equipment, welding medium, etc., can solve the problems of high cost, unsatisfactory packaging conditions, application restrictions, etc., and achieve short cycle and good welding effect , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

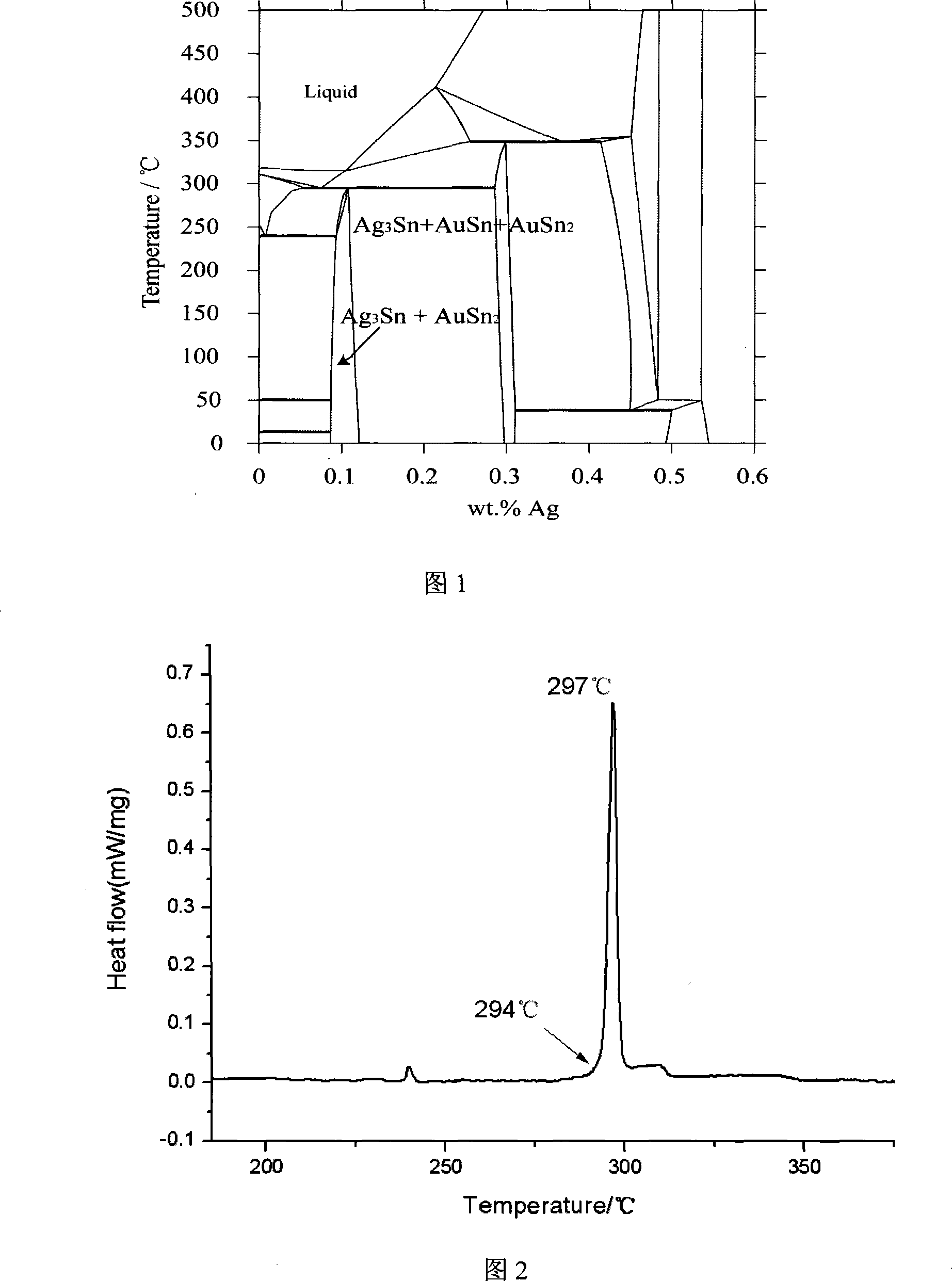

[0019] Embodiment 1: Preparation of Sn12Ag40Au solder alloy

[0020] Weigh 12% silver with a purity of 99.9%, 40% gold with a purity of 99.99%, and the balance tin with a purity of 99.5%. Vacuum seal the above silver, gold, tin and other raw materials in a quartz tube to ensure that the vacuum in the quartz tube is below 5Pa, and then fill it with high-purity argon to (0.7~0.8)×10 5 Pa, and then smelting and heat treatment in a 750°C reaction furnace for a holding time of 24 to 36 hours to obtain a tin-silver-gold lead-free solder alloy. Take out the heat-treated tin-silver-gold lead-free solder material alloy and quickly quench it in ice water, then vacuum-pack it and put it in an oven at 150°C for at least 24 hours of homogenization and annealing. After taking it out and cooling it, use wire cutting method Slicing (thickness 0.4-0.8mm) and disc-shaped material, that is, finally obtaining the DSC sample required by the present invention and the sample size for testing electr...

Embodiment 2

[0030] Embodiment 2: Preparation of Sn13Ag38Au solder alloy

[0031] Weigh 13% silver with a purity of 99.9%, 38% gold with a purity of 99.99%, and the balance tin with a purity of 99.5%. Vacuum seal the above silver, gold, tin and other raw materials in a quartz tube to ensure that the vacuum in the quartz tube is below 5Pa, and then fill it with high-purity argon to (0.7~0.8)×10 5 Pa, and then smelting and heat treatment in a reaction furnace at 800°C for a holding time of 24 to 36 hours to obtain a tin-silver-gold lead-free solder alloy. Take out the heat-treated tin-silver-gold lead-free solder material alloy and quickly quench it in ice water, then vacuum-pack it and put it in an oven at 150°C for at least 24 hours of homogenization and annealing. After taking it out and cooling it, use wire cutting method Slicing (thickness 0.4-0.8mm) and disc-shaped material, that is, finally obtaining the DSC sample required by the present invention and the sample size for testing ele...

Embodiment 3

[0039] Embodiment 3: Preparation of Sn10Ag37Au solder alloy

[0040] Weigh 10% silver with a purity of 99.9%, 37% gold with a purity of 99.99%, and the balance tin with a purity of 99.5%. The above-mentioned silver, gold, tin and other raw materials were used to prepare the solder alloy according to the method of Example 1, wherein the heat treatment temperature was 600°C.

[0041] The German Netzsch STA 404 was used for DSC testing. The temperature rise rate was 8°C / min between room temperature and 180°C; the temperature rise rate was 2°C / min between 180°C and 380°C, and the sample mass was less than 20mg. The melting temperature of the alloy ranges from 292 to 297°C.

[0042] The temperature-controlled thermocouple and German Kruss DSA 100 were used to test the wetting performance of the above alloy. It was obtained that the wetting angle between the solder and the Cu substrate (industrial copper sheet T3) reached 25 degrees in the air (aerobic condition). as shown in Tabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com