Method for producing dialkyl carbonate

A technology of dialkyl carbonate and alkaryl, which is applied in the field of oxidative carbonylation of alcohol compounds to produce dialkyl carbonate, which can solve the problem of low production capacity of dimethyl carbonate, unsolved problems of equipment corrosion, and the use of catalysts. Large volume and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] Conversion rate, selectivity and productive rate recorded in the description of the present invention are calculated according to the following methods:

[0032] Conversion rate (%)=reacted methanol (mol) / methanol feed amount (mol)×100%

[0033] Selectivity (%)=2× output of dimethyl carbonate (mol) / reacted methanol (mol)×100%

[0034] Yield (%) = Conversion (%) × Selectivity (%) × 100%

Embodiment 1

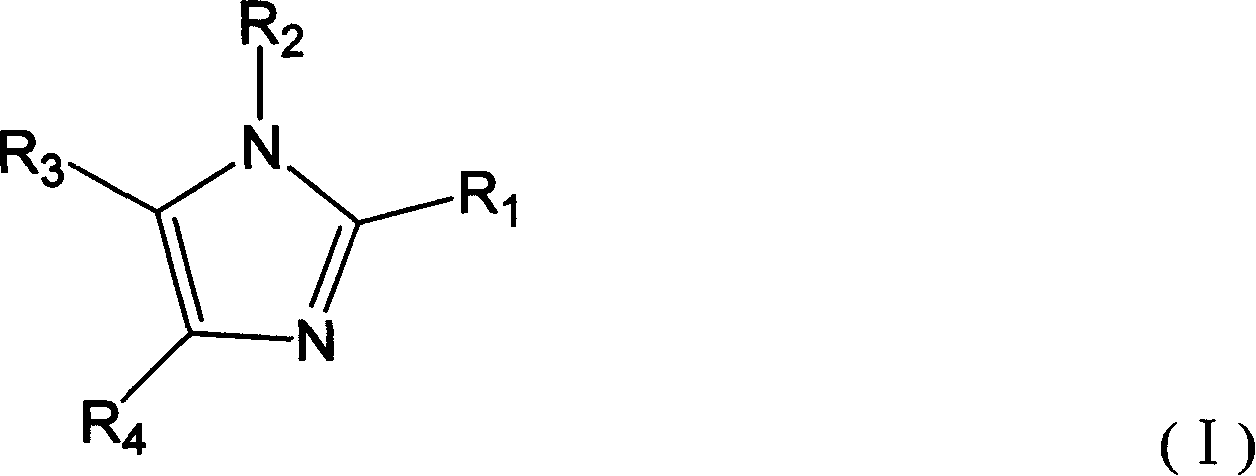

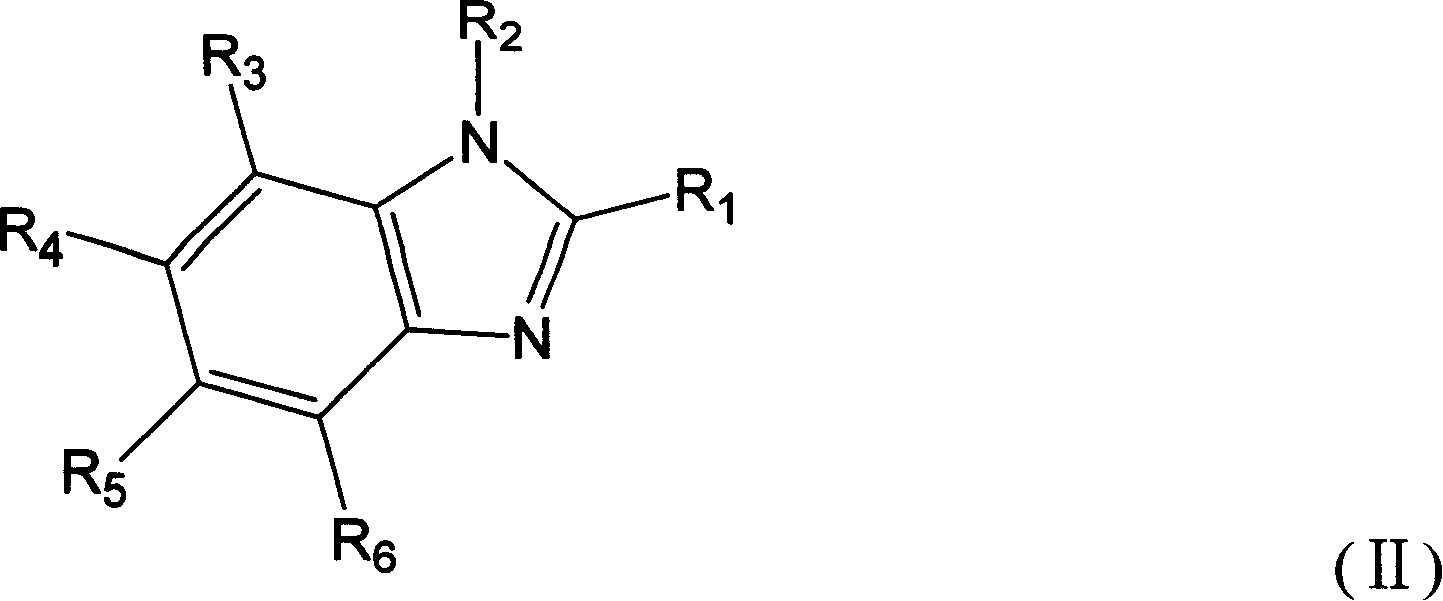

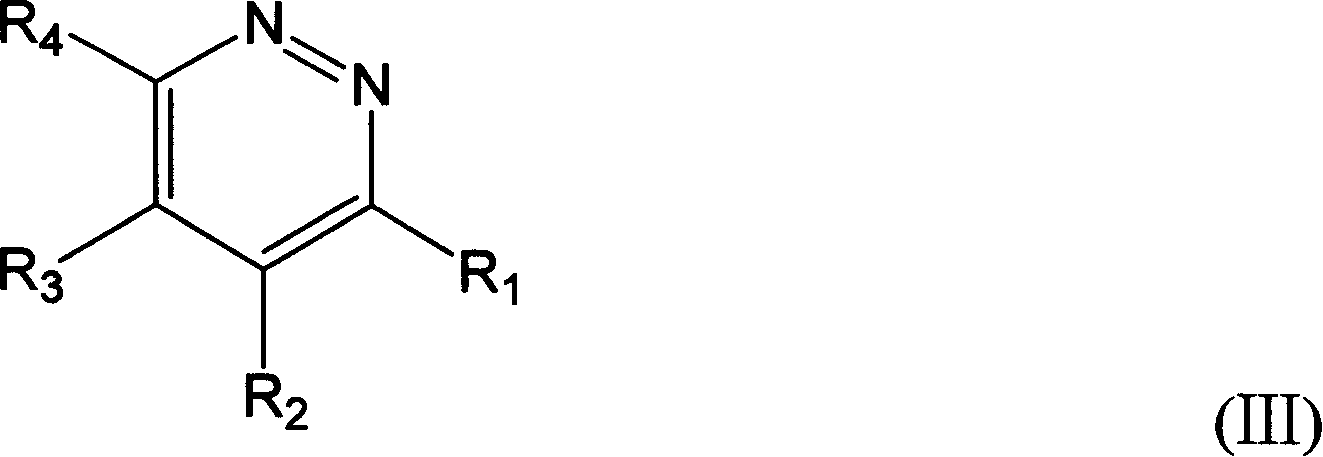

[0040] Repeat the steps of Comparative Example 1, and further add 2-methylimidazole as a co-catalyst, the number of moles of the co-catalyst is twice the number of moles of copper halide. The product was analyzed by gas chromatography, and the conversion, selectivity, and yield were calculated, and the results were recorded in Table 1.

Embodiment 2-7

[0042] Repeat the steps of Example 1, and use different catalysts and cocatalysts to react according to the list in Table 1. The product was analyzed by gas chromatography, and the conversion, selectivity, and yield were calculated, and the results were recorded in Table 1.

[0043] Table 1

[0044] catalyst

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com