Process for preparing polycarbonate

A technology of polycarbonate and impingement flow reactor, which is applied in the field of preparing polycarbonate by interface phosgene method, can solve the problems of low mixing efficiency and dissipation, and can strengthen the dispersion and transfer process, improve the reaction efficiency and molecular weight distribution. narrow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

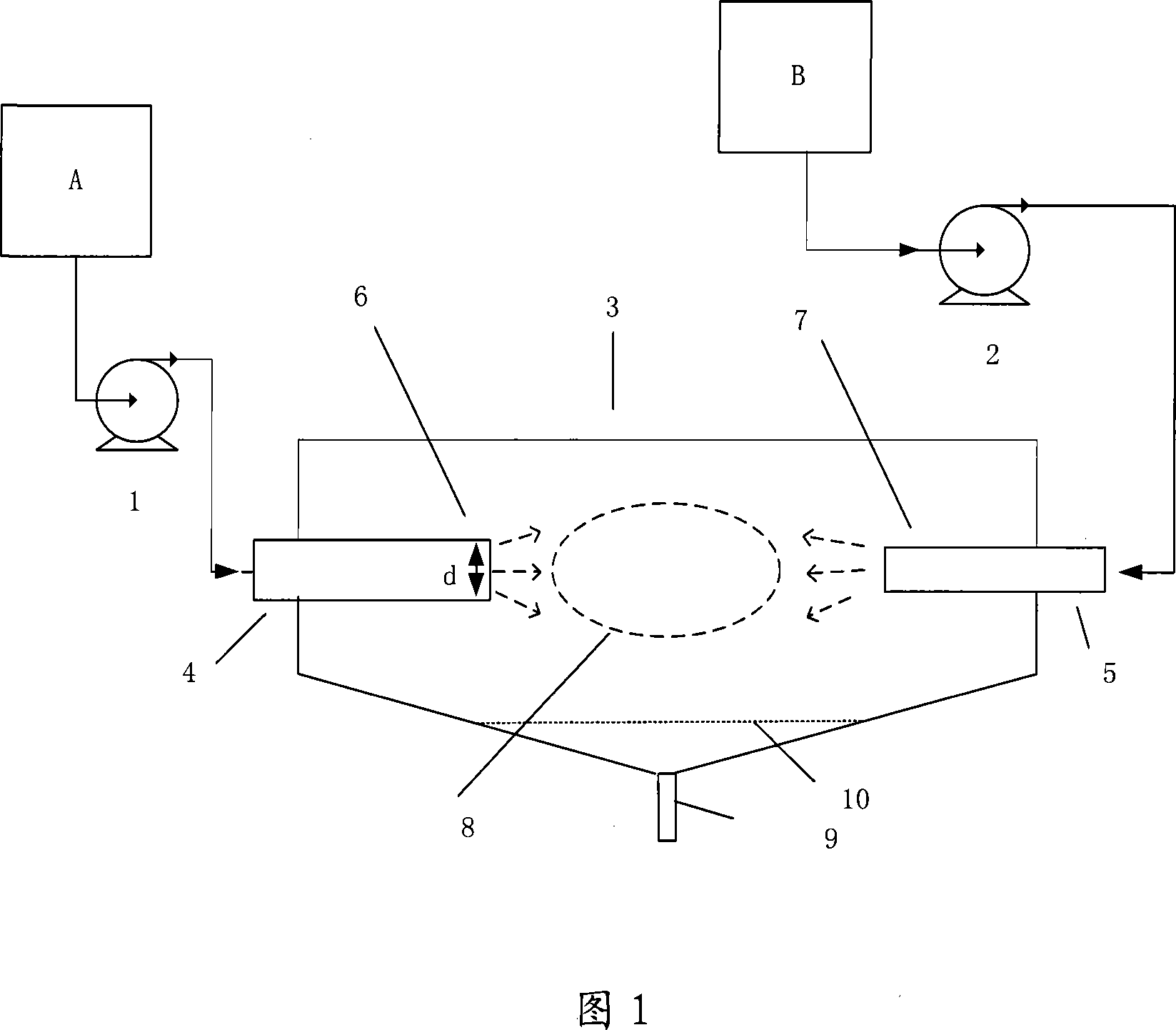

Method used

Image

Examples

Embodiment 1

[0040] Add 206.6g of bisphenol A, 2925g of water and 146g of 50% by mass sodium hydroxide solution into premix tank A to form an aqueous phase, and in premix tank B, mix 84g of liquid phosgene with 2095g of dichloromethane to form an organic phase , the water phase and organic phase materials are respectively input into the feed pipe of the nozzle-type impact flow reactor through the pump, so that the material is sprayed through the nozzle into the central area of the impact zone at a high speed, and the speed of the material entering the entrance of the impact zone is 1.7 m / s , with a residence time of 24 seconds in the impinging flow reactor. Then the reaction solution enters the reactor E, and 2.19g of phenol and 1.85g of 50% by mass sodium hydroxide aqueous solution are added to make the solution pH value 11.5. After reacting for 45 minutes, 1.03g of triethylamine and 50% by mass of sodium hydroxide aqueous solution are added, The pH of the solution was brought to 11.5 a...

Embodiment 2

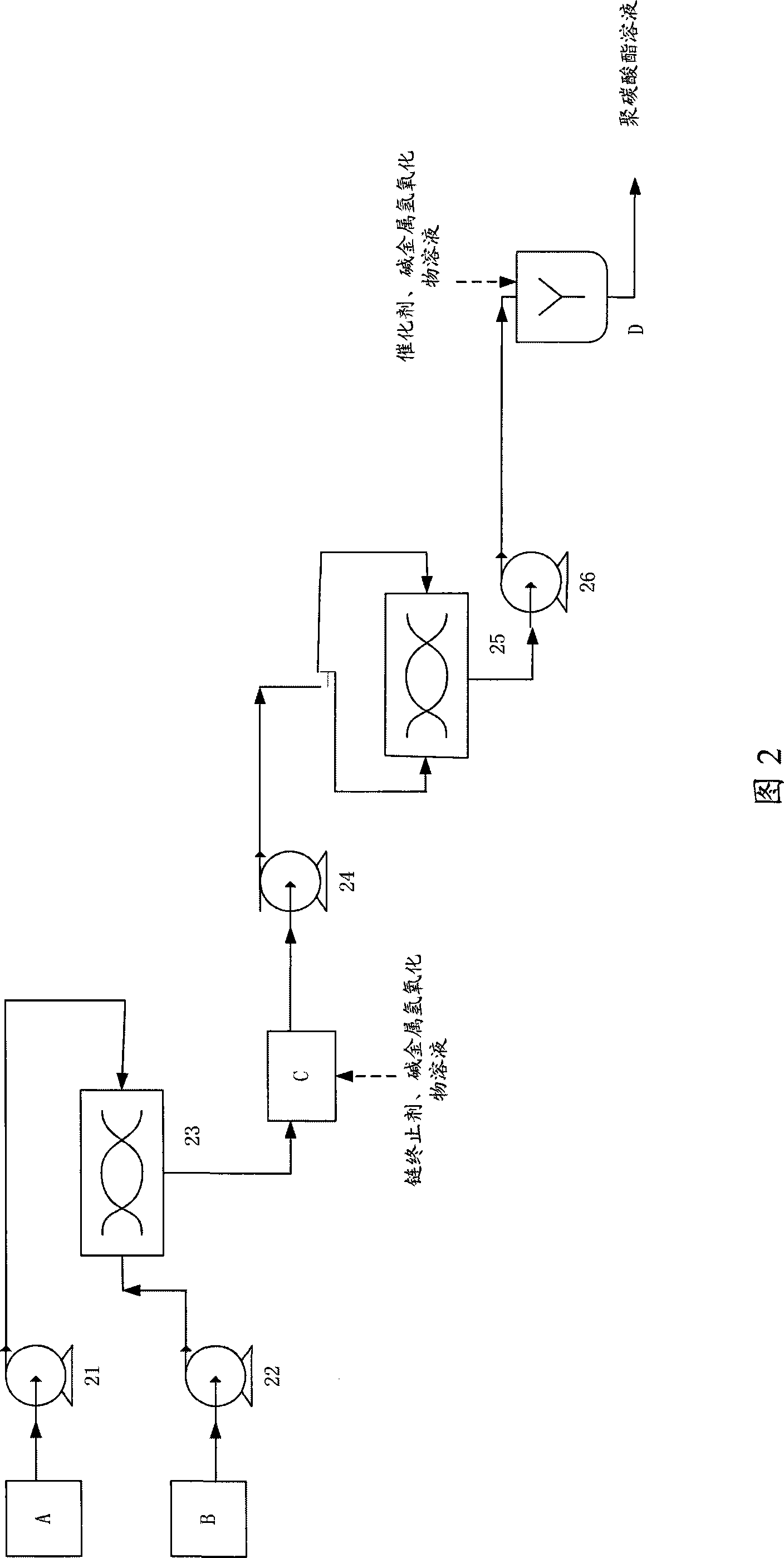

[0042] Add 206.6g of bisphenol A, 2925g of water and 146g of 50% by mass sodium hydroxide solution in the premixing tank A and mix to form an aqueous phase. In the premixing tank B, 83g of liquid phosgene and 2000g of dichloromethane are mixed to form an organic phase. The water phase and organic phase materials are respectively input into the feed pipe of the nozzle-type impingement flow reactor through the pump. Under the action of pressure, the materials are injected into the center of the impact zone through the nozzle at high speed, and the material enters the impact zone at an inlet speed of 3.8 m / s. , with a residence time of 5 seconds in the impactor reactor. After the reaction, the reaction solution enters the intermediate tank C, adds 2.19g of phenol and 1.85g of 50% by mass sodium hydroxide solution to make the pH value of the solution 11.5, and enters into the feed pipe of another nozzle-type impingement flow reactor by a pump respectively, The velocity of the mate...

Embodiment 3

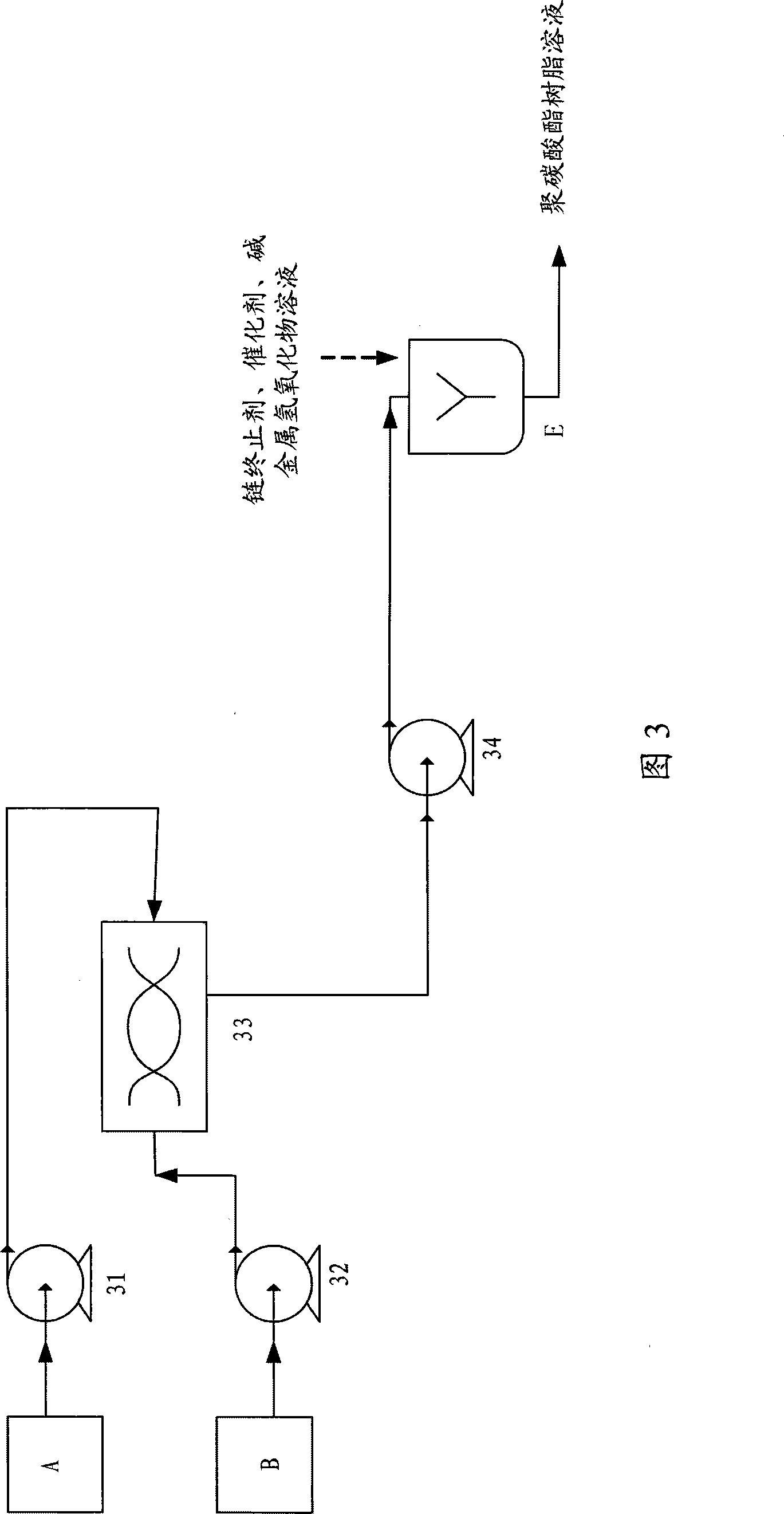

[0044] Add 207.4g of bisphenol A, 2925g of water and 146g of 50% by mass sodium hydroxide solution into the premixing tank A to form an aqueous phase, and in the premixing tank B, mix 84g of liquid phosgene and 2095g of dichloromethane to form an organic phase , the water phase and organic phase materials are respectively input into the feed pipe of the nozzle-type impact flow reactor through the pump, and the material is injected into the center of the impact area through the nozzle at a high speed under the pressure, and the material enters the impact area at an inlet speed of 2.1 m / seconds, with a residence time of 20 seconds in the impact reactor. Then the reaction solution enters the intermediate tank C, adds 1.46g phenol and 1.85g50 mass% sodium hydroxide solution, makes the solution pH value 11.8, and enters respectively in the feed pipe of another nozzle type impinging flow reactor by a pump, the material The inlet velocity into the impact zone is 3.2 m / s, and the res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com