Oil gas separation ceramic compound film tube and component and preparation thereof

A ceramic composite membrane, composite membrane tube technology, applied in separation methods, chemical instruments and methods, semi-permeable membrane separation and other directions, can solve problems such as breakage, oil leakage, deformation of polymer hollow fiber composite membrane components, etc., to reduce the dosage , cost reduction, and the effect of fast ventilation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

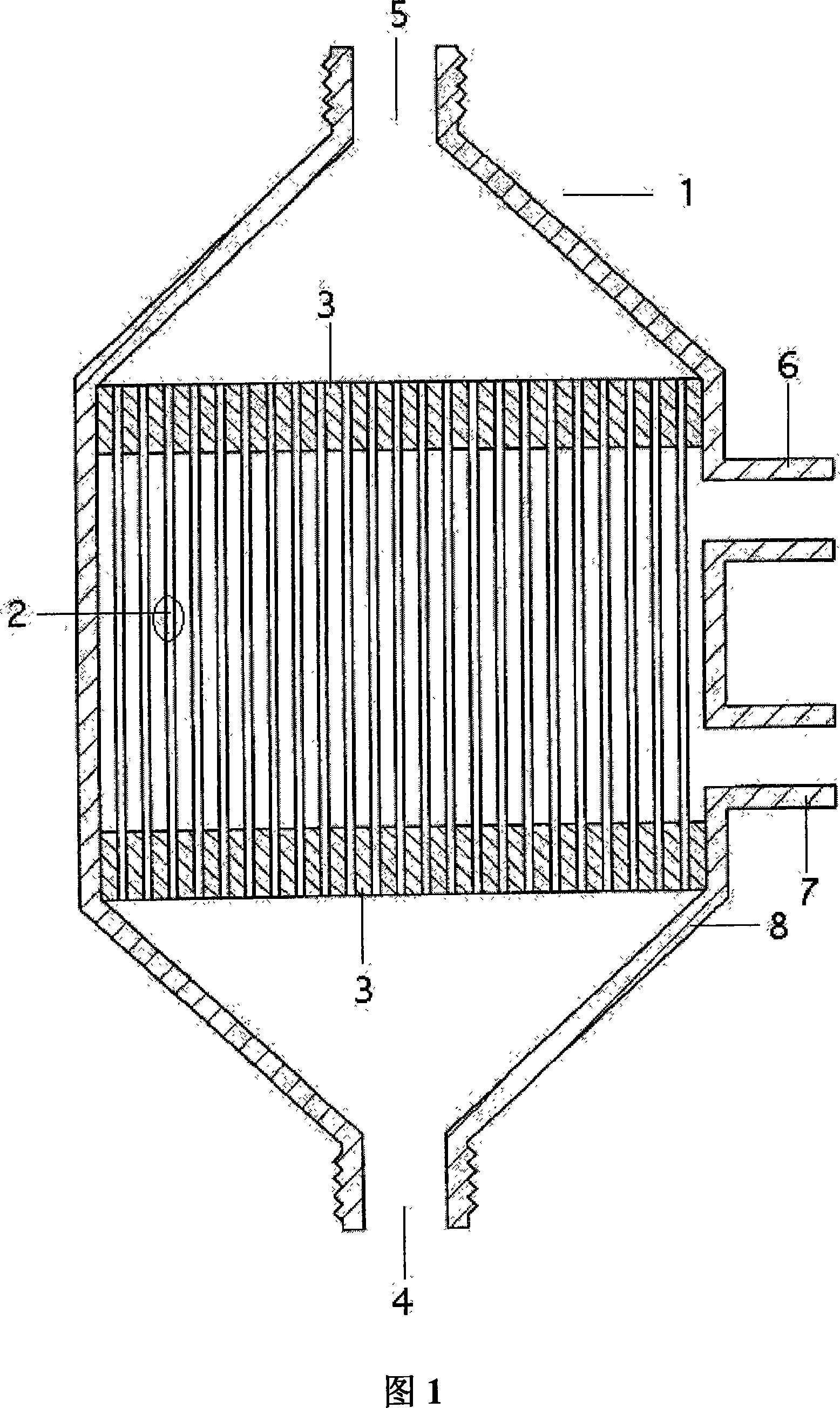

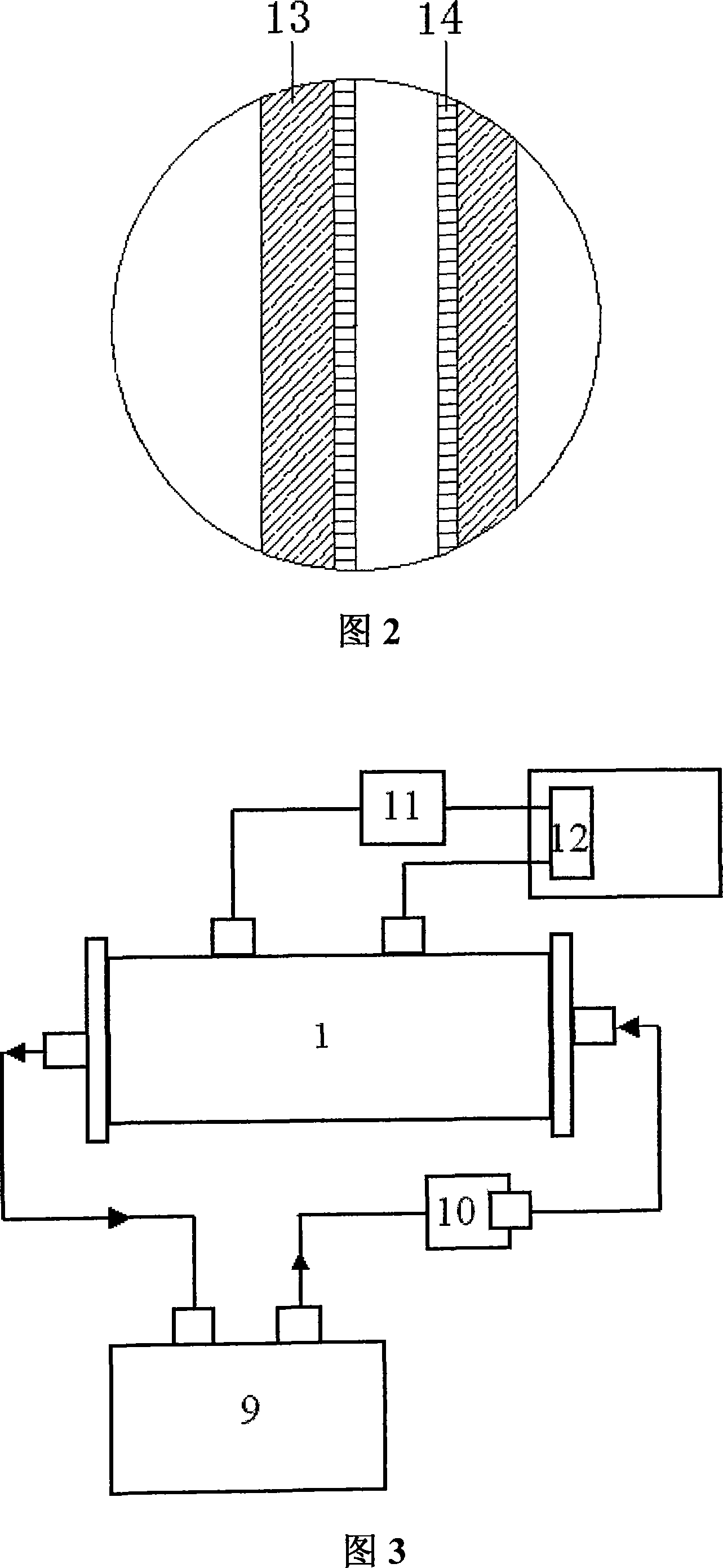

Embodiment 1

[0021] An internal pressure ceramic membrane tube with a pore diameter of 50nm is selected. The inner diameter of the ceramic tube is 10mm, the outer diameter is 12.5mm, and the length is 100mm. Clean it with ethanol solution. The separation layer is selected from Teflon AF2400 solution produced by DuPont Company of the United States, and the concentration of the solution is 1.0% by weight. Pour the polymer solution into a film tube temporarily sealed at one end, keep pouring it out for 0.5min, apply it repeatedly 7 times, heat up to 200°C for drying treatment, and remove the solvent. The thickness of the separation layer can be determined from the cross-sectional scanning electron microscope to be about 5 μm. The assembly formed by the membrane and the stainless steel casing is connected with a small simulated transformer in the laboratory, tested with an online oil chromatography system, and the oil-gas balance can be reached within 2 hours. The component was filled with oi...

Embodiment 2

[0023] An internal pressure ceramic membrane tube with a pore diameter of 100nm is selected. The inner diameter of the ceramic tube is 10mm, the outer diameter is 12.5mm, and the length is 100mm. Clean it with ethanol solution. The separation layer was selected from Hyflon AD80 produced by Solvay Solexis, and the solvent was Galden HT90 solution with a concentration of 8.0% by weight. Pour the polymer solution into a film tube that is temporarily sealed at one end, keep pouring out for 1 min, coat once, heat up to 250°C for drying, and remove the solvent. The assembly formed by the membrane and the stainless steel casing is connected with a small simulated transformer in the laboratory, tested with an online oil chromatography system, and the oil-gas balance can be reached within 4 hours. The component was filled with oil and kept under 500kPa pressure for 48 hours without any rupture or oil leakage.

Embodiment 3

[0025] Select an external pressure ceramic tube with a pore diameter of 100nm, the inner diameter of the ceramic tube is 10mm, the outer diameter is 13.0mm, and the length is 100mm, and it is cleaned with ethanol solution. The separation layer was selected from Hyflon AD80 produced by Solvay Solexis, and the solvent was Galden HT90. After dissolving the polymer, add 5% of the total hydrophobic nano-SiO 2 , ultrasonic dispersion. The average particle size of the nanometer powder is 20nm, and the total weight percent concentration of solids in the solution is 1.0%. Pour the polymer solution into a film tube that is temporarily sealed at one end, keep pouring it out for 8 minutes, coat it 6 times, heat it up to 200°C for drying treatment, and remove the solvent. The assembly formed by the membrane and the stainless steel casing is connected with a small simulated transformer in the laboratory, tested with an online oil chromatography system, and the oil-gas balance can be reach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com