Midbody for producing prasugrel and producing method thereof

A technology of intermediates and compounds, which is applied in the field of prasugrel intermediates and its preparation, can solve problems such as harsh reaction conditions, n-butyl lithium is flammable and explosive, and large-scale production hazards, and achieves mild and suitable reaction conditions. For large-scale industrial production, the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~2

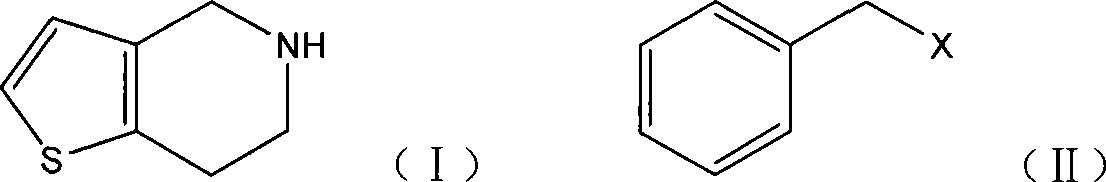

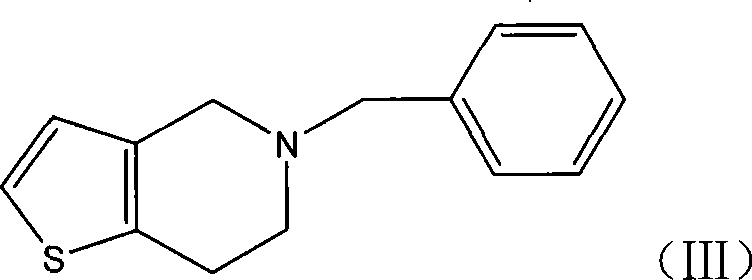

[0028] Preparation of 5-benzyl-4,5,6,7-tetrahydrothieno[3,2-c]pyridine (formula III):

[0029] 4,5,6,7-tetrahydrothieno[3,2-c]pyridine (7.0g), potassium carbonate (7.2g) and acetonitrile (50ml) were mixed, benzyl chloride (6.1g) was added, stirred for 0.5 After 3 hours it was refluxed for 3 hours. Cool, filter, concentrate the filtrate to dryness, add ethyl acetate (30ml) and water (50ml), separate the layers, extract the aqueous layer with ethyl acetate (30ml×2), combine the organic layers, wash with water, dry, and concentrate to dryness to obtain 8.3 g of the title compound 5-benzyl-4,5,6,7-tetrahydrothieno[3,2-c]pyridine, yield 90.8%.

[0030] 4,5,6,7-tetrahydrothieno[3,2-c]pyridine (18.0g), potassium carbonate (18.6g), benzyl chloride (15.0g), sodium iodide (0.8g) in DMF ( 100ml) was stirred for 0.5 hours, then reacted at 80°C for 3 hours, cooled, added water (150ml) and ethyl acetate (100ml), separated, and the aqueous layer was extracted with ethyl acetate (50ml×2). ...

Embodiment 3

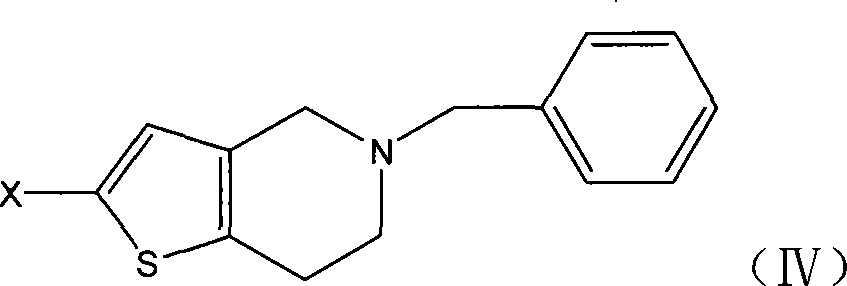

[0032] Preparation of 2-bromo-5-benzyl-4,5,6,7-tetrahydrothieno[3,2-c]pyridine (formula IV):

[0033] The compound (23.2g) obtained in Example 2 was dissolved in acetic acid (100.0ml), 40% hydrobromic acid (75.0ml), methanol (100ml), and the methanol of 30% hydrogen peroxide (33.0ml) was added dropwise under ice-water bath cooling (100ml) solution, stirred at room temperature for 3 hours. Sodium thiosulfate solution (150ml) was added dropwise, then saturated sodium carbonate solution was added dropwise until the pH was 9, extracted with dichloromethane (100ml×3), the organic layers were combined, washed with water, dried, and concentrated to dryness to obtain 30.5g of light yellow solid , yield 97.8%.

Embodiment 4

[0035] Preparation of 2-methoxy-5-benzyl-4,5,6,7-tetrahydrothieno[3,2-c]pyridine:

[0036] Dissolve sodium (24.0g) in methanol (350ml), concentrate to dryness, add dioxane (300ml), 2-bromo-5-benzyl-4,5,6,7-tetrahydrothieno[3, 2-c] Pyridine (30.5g), cuprous bromide (1.5g) and sodium iodide (0.8g), stirred and refluxed for 16 hours. Cool, filter and wash with methanol, concentrate the filtrate to dryness, add ethyl acetate (150ml) and water (250ml), separate the layers, extract the aqueous layer with ethyl acetate (100ml×2), combine the organic layers, and ethylenediaminetetraacetic acid Wash with disodium solution (100ml×2), brine (100ml×3), dry, and concentrate to dryness to obtain 29.3g of oily substance. Ethyl acetate (200ml) was added, and the ethanol solution of hydrogen chloride was added dropwise to pH 1, stirred in an ice-water bath for 1 hour, filtered, washed with ethyl acetate, and dried to obtain 24.0 g of light yellow solid, yield 82.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com