Method for producing bismuth and enriched silver from high-silver bismuth alloy

A high-silver bismuth and alloy technology is applied in the fields of extraction and refining of bismuth, preparation of high-purity bismuth and effective enrichment of precious metals, which can solve the problems of long smelting process, long process flow, serious environmental pollution and the like, and reduce the consumption of chlorine gas. The effect of increasing the direct yield and low comprehensive cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

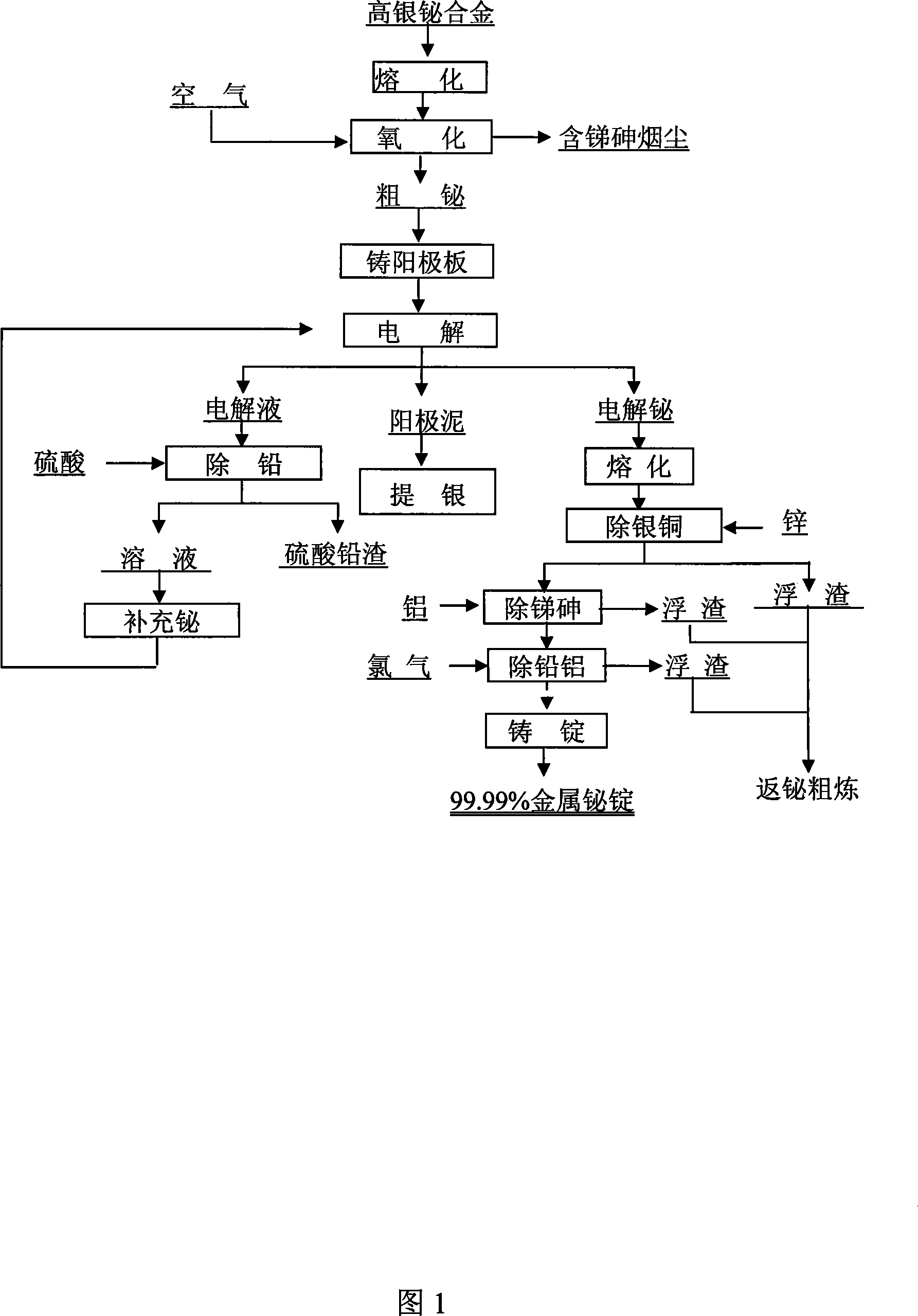

Image

Examples

Embodiment 1

[0045] Embodiment 1: take the thick bismuth obtained after smelting the complex bismuth-containing material as raw material, the weight of thick bismuth is 700Kg, and its chemical composition (wt%) is: Bi 81.3, Pb 6.1, Sb 3.48, As 0.4, Cu 1.46 Ag6 .33, Au 100g / t; industrial fluosilicic acid, its concentration is 40%; industrial sulfuric acid, its concentration is 98.0%; industrial bismuth oxide, of which Bi 2 o 3The content of zinc is 99.5%; industrial zinc ingots, with a zinc content of more than 99.0%, are processed into zinc chips; electrolytic aluminum ingots, with an aluminum content of 99.3%, are processed into aluminum flakes; industrial ammonium chloride, NH 4 The content of Cl is 99.3%; gelatin and β-naphthol are industrial grades, which are respectively prepared into 10g / l aqueous solution; industrial titanium plate is made into a cathode plate of 390×510mm; it is welded with polypropylene plastic to make 4×0.5×0.8 m industrial electrolyzer.

[0046] Melt the crude...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com