Method for producing alcohol by starchy materials big tank and non-vector immobilized yeast continuous fermentation

A carrier-free immobilization technology of starchy raw materials, applied in the field of microbial fermentation engineering, can solve the problems of reduced equipment utilization, low resource utilization, and increased sewage load, so as to reduce the formation of retained materials, improve the growth environment, The effect of improving the utilization rate of starch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

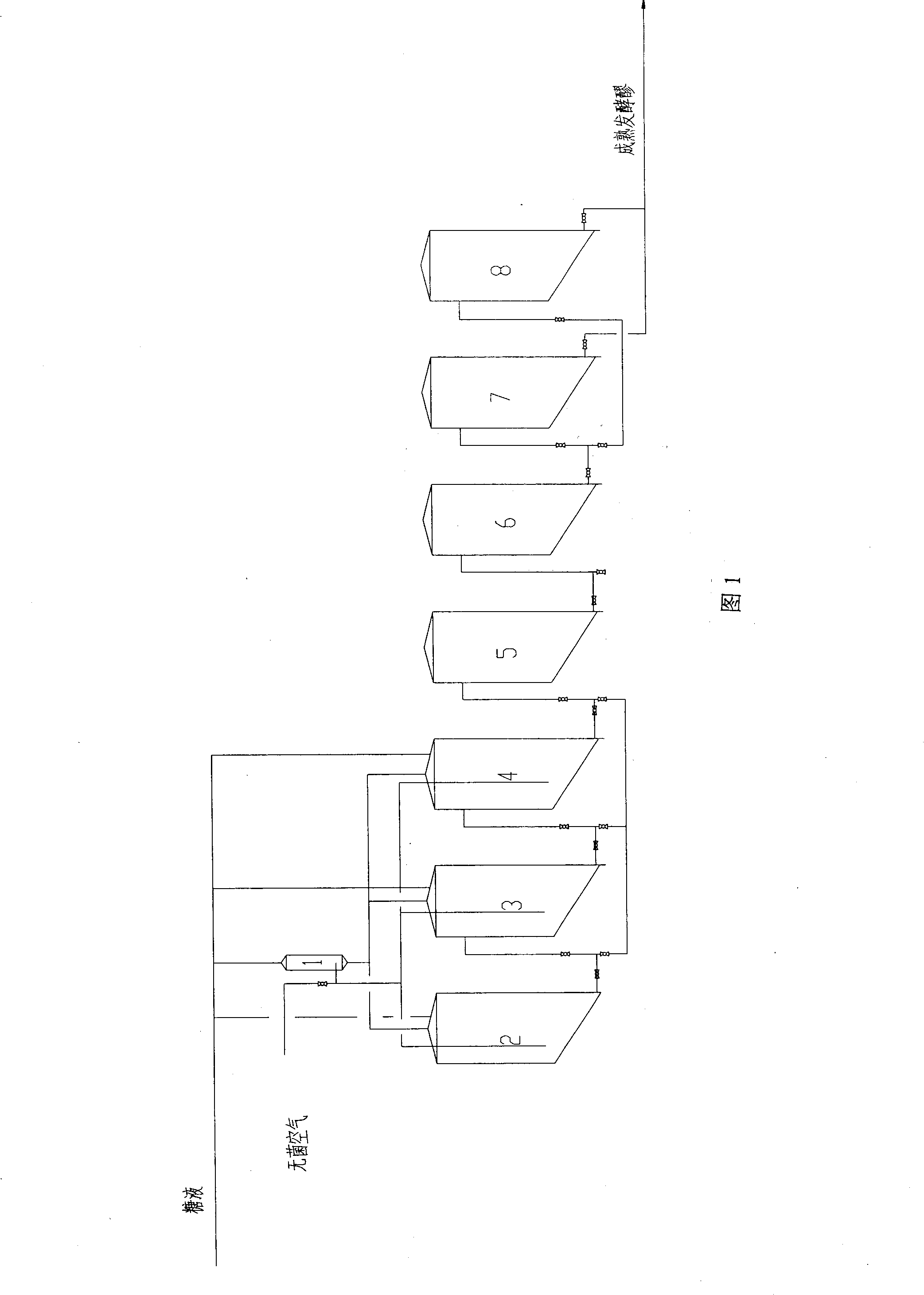

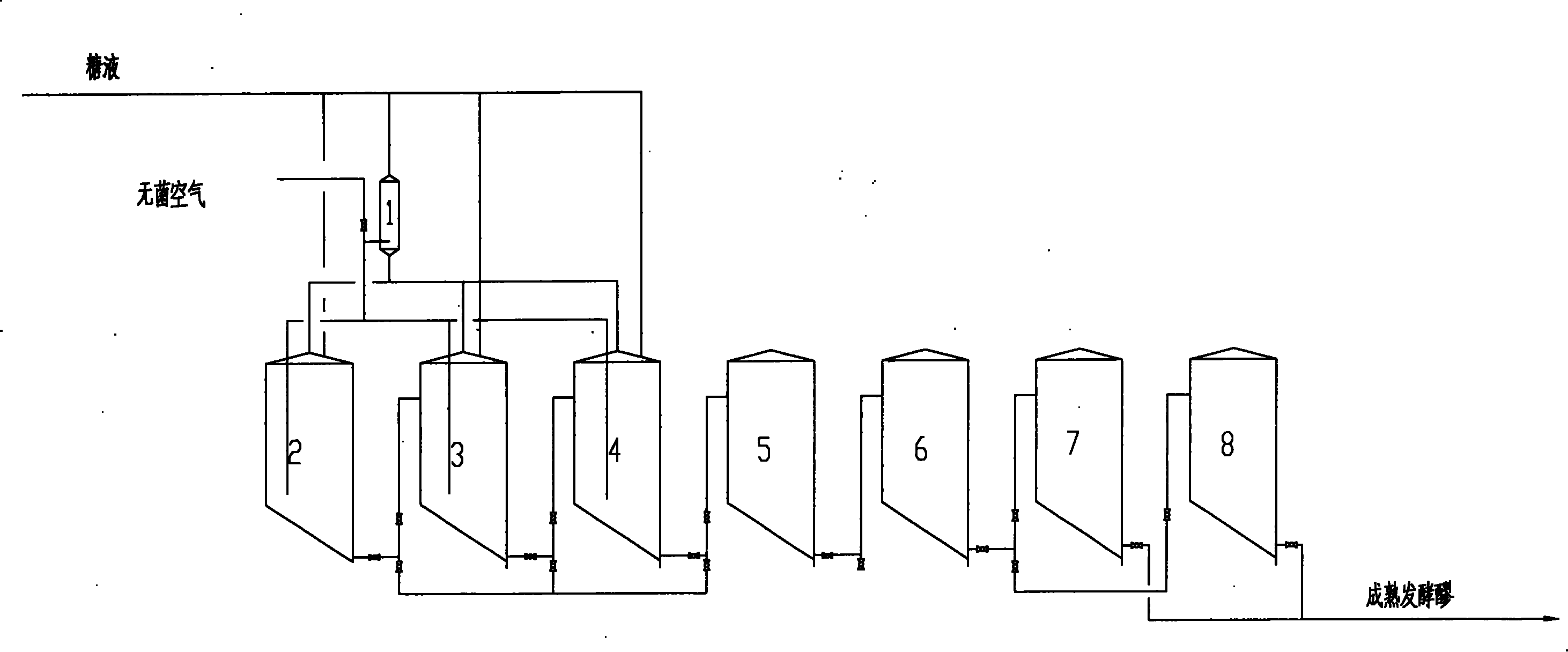

Image

Examples

Embodiment

[0043] Embodiment: Large tank, the method for continuous fermentation of immobilized yeast without carrier to produce alcohol

[0044] 1. Pretreatment of starchy raw materials

[0045]The starchy raw material is pulverized in one stage, and the particle size is controlled at 1.5-1.8 mm, then stirred with water at 55-65 °C, and the pulverized raw material is mixed with distilled waste water and fresh water (weight ratio 60:40) to obtain For powder slurry, add high-temperature-resistant α-amylase to the prepared powder slurry, and add it continuously and uniformly in an amount of 2 to 5 μ / g raw materials. After stirring evenly, seal and heat to 67-89°C in the slurry tank, and maintain it for 30 ~60 minutes.

[0046] Then the powder slurry is cooked at medium temperature, the cooking temperature is controlled at 100-110 °C, the cooking temperature is 2 hours, the gelatinization rate is controlled at 85-95%, the paste liquid is vacuum-cooled to 60-62 °C, glucoamylase is added, mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com