Biomass energy circulation electrification technique as well as generating system thereof

A technology of biomass energy and cycle power generation, which is applied in the direction of biofuel, fuel oil system, petroleum industry, etc., can solve the problems of low system utilization efficiency, heat loss, high operating cost of power plants, etc., to reduce system investment and water pump operating cost, improve The efficiency of power generation and the effect of increasing waste heat power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

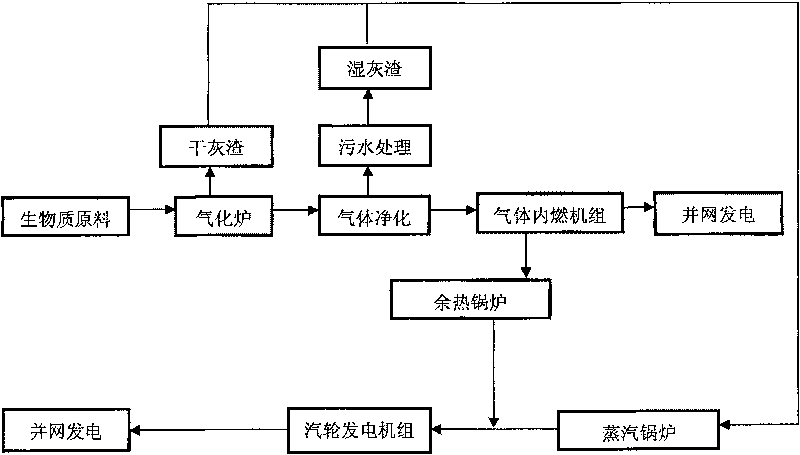

[0036] Embodiment 1 of the present invention is as Figure 1~3 As shown, the present invention can be popularized and applied by cooperating with a large rice factory to set up a power plant or setting up a biomass power plant in a grain production base. The scale of the power plant can be selected according to the local biomass resources, generally 5MW and 10MW.

[0037] The biomass power generation process of the present embodiment comprises the following steps:

[0038] (1) Treat biomass raw materials, such as crushing plant straw raw materials, and chaff raw materials can be used directly, and then gasify biomass raw materials, that is, convert solid biomass into combustible gases. The main source of these combustible gases Composition is CO, H 2 、CH 4 , CO 2 etc. The gas produced by gasification also contains certain impurities, such as ash, coke, a small amount of tar, etc.; after dedusting, decoking and purification, it is sent to the gas internal combustion unit for...

Embodiment 2

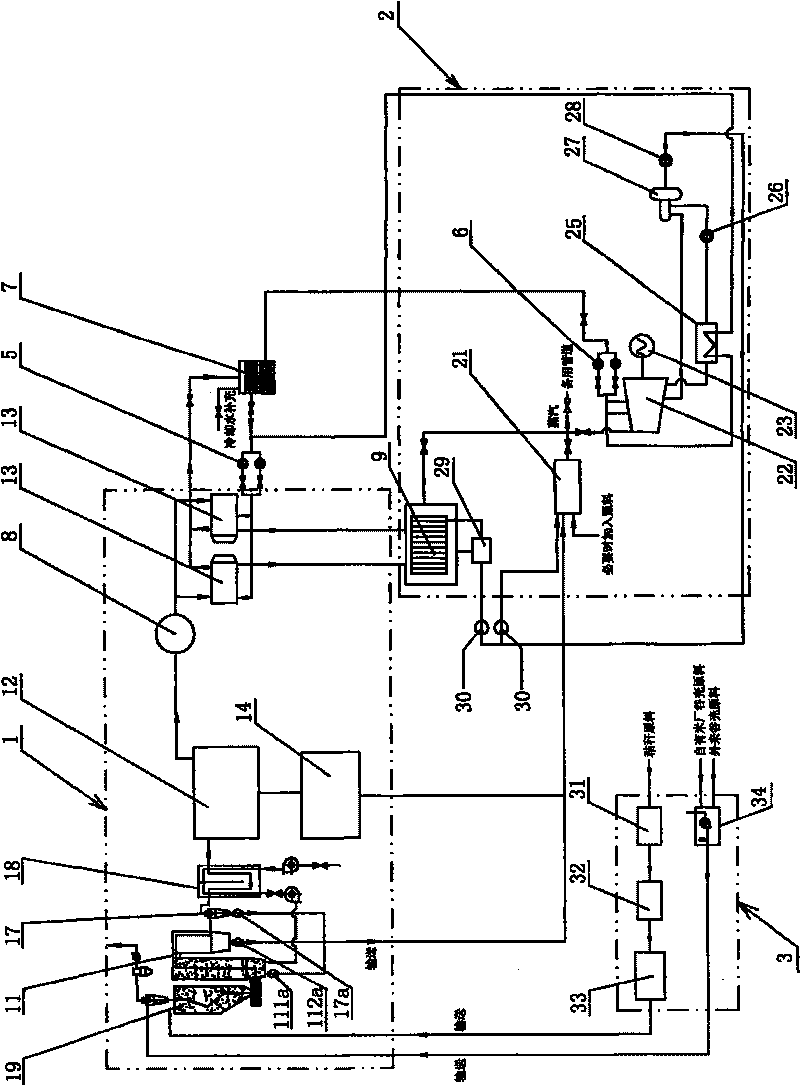

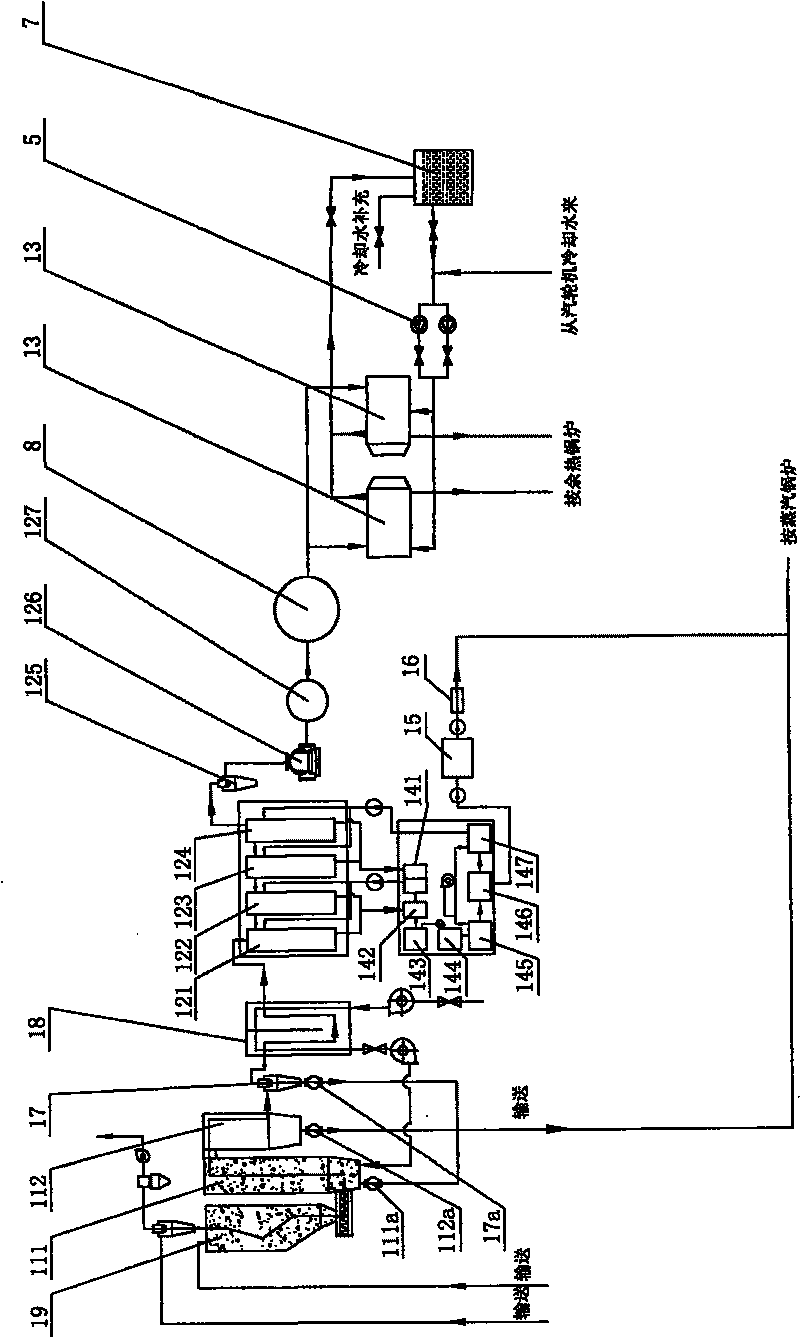

[0045] Embodiment 2 of the present invention is as Figure 4~7 As shown, the difference from the previous embodiment is that in the process of biomass power generation, in step 2, the high-temperature gas waste heat at the outlet of the gasifier 11 is first sent to the heat exchanger 18 to generate a steam-water mixture, The steam-water mixture is then fed into the waste heat boiler 9 or the steam boiler 21, or respectively sent to the waste heat boiler 9 and the steam boiler 21 for combustion to further generate superheated steam, and then transfer to step 3 to drive the turbogenerator unit to generate electricity;

[0046] In step 2, the dry ash produced after the gasification of the biomass raw material and the wet ash produced after the purification of the combustible gas are first mixed, and then sent to the steam boiler 21 for combustion;

[0047] In step 2, when necessary, the biomass raw material and ash are directly mixed in the steam boiler 21 and then burned to gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com