Method for testing pyromellitic acid anhydride purity and organic impurity

A technology of pyromellitic dianhydride and organic impurities, which is applied in the detection field of pyromellitic dianhydride purity and organic impurities, can solve the problems of meaningless data, no PMDA testing standard, and inability to accurately determine the purity, etc. Achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

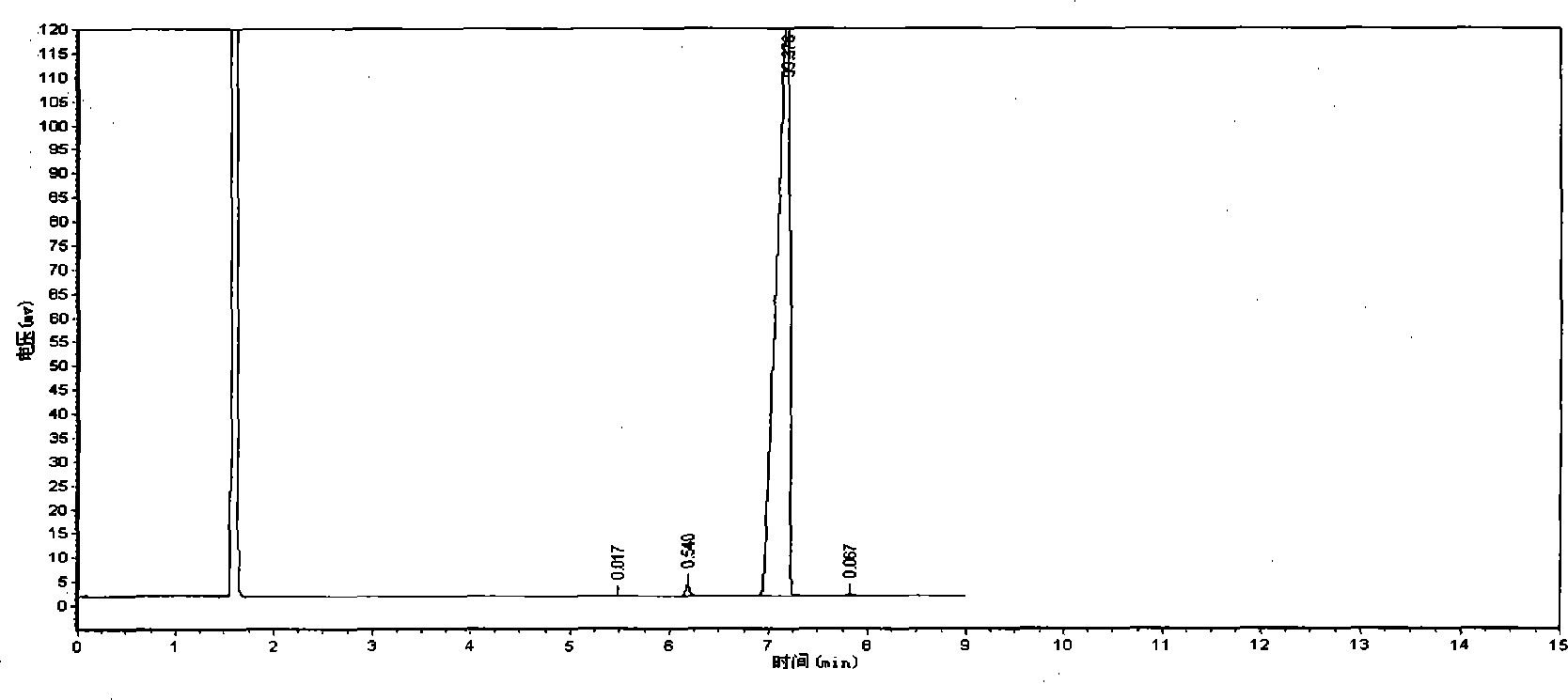

Embodiment 1

[0040] A) ethyl esterification reaction, accurately weigh the refined PMDA sample of 0.100g, place in the 100ml single hole round bottom flask, add 5ml with Na without water of crystallization 2 CO 3 After the dehydration treatment, connect the condenser to the flask, and reflux at 78°C for 35 minutes to completely esterify the ethyl ester. Transfer the product after the ethyl esterification reaction together with the excess ethanol to a glass watch glass and move it into a vacuum drying oven for slow drying. The excess ethanol was removed by slow evaporation to obtain a white powdery crystalline solid;

[0041]B) Methyl esterification reaction, weigh 23 mg of ethyl esterified crystals obtained by step A) and place in a 5ml esterification bottle, add excess diazomethane saturated ether solution to carry out methyl esterification reaction in the esterification bottle , until no bubbles are produced and the solution is light yellow, the methyl esterification reaction is over, a...

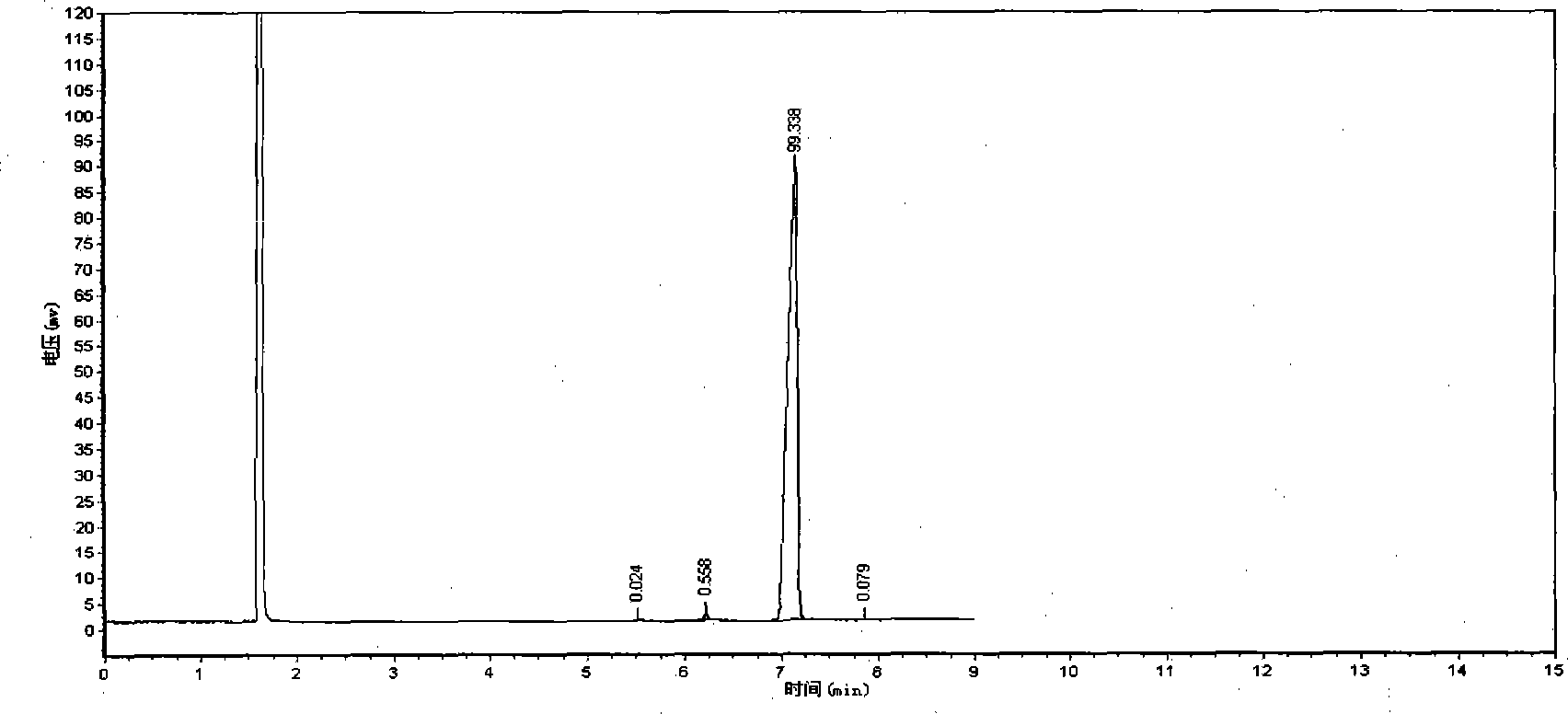

Embodiment 2

[0043] Only change the amount of the refined PMDA sample into 0.098g in the step A), add Na 2 CO 3 Change the absolute ethanol after dehydration to 6ml, change the reflux temperature to 79°C, and change the reflux time to 40min; change the amount of ethyl esterified crystals in step B) to 20mg, and change the temperature of the constant temperature water bath for evaporation to remove ether Change to 55°C, use a pipette to transfer the volume of chromatographically pure chloroform (diluent) to 0.5ml, and change the gas chromatography injection volume to 0.2μl. All the other are with embodiment 1.

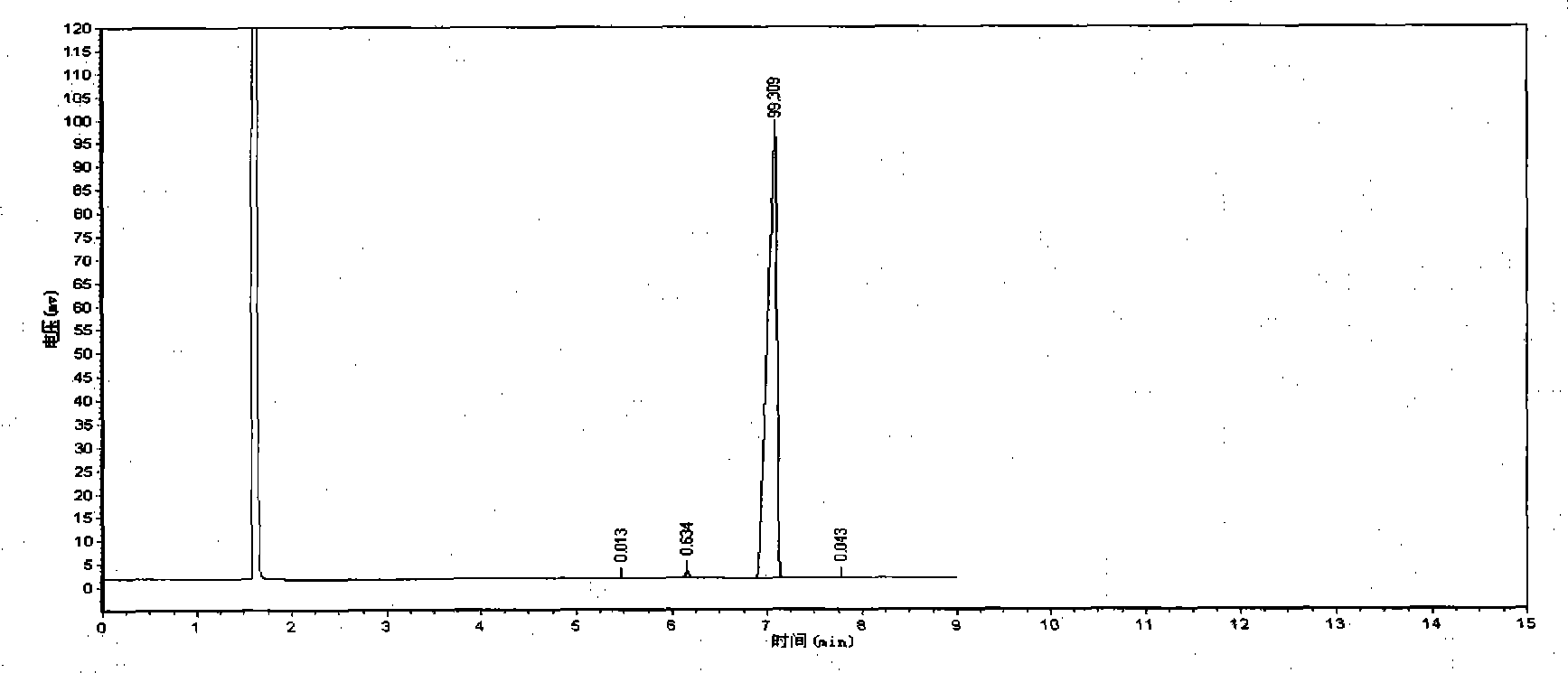

Embodiment 3

[0045] Only change the amount of the refined PMDA sample into 0.095g by weighing, add Na with no water of crystallization 2 CO 3 Change the absolute ethanol after dehydration to 5.5ml, change the reflux temperature to 80°C, and change the reflux time to 30min; change the amount of ethyl esterified crystals in step B) to 30mg, and change the constant temperature water bath that evaporates and removes ether The temperature was changed to 65° C., the volume of chromatographically pure chloroform (diluent) pipetted with a pipette was changed to 0.9 ml, and the gas chromatography injection volume was changed to 0.4 μl. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com