Powder fire-proof paint containing bromine-carbon polyester and preparation method thereof

A technology of bromocarbon polyester and fire retardant coatings, applied in powder coatings, fire retardant coatings, polyester coatings, etc., can solve the problem that the decorative and water resistance physical and mechanical properties of fire retardant coatings are difficult to meet the requirements, and the film-forming substances of fire retardant coatings do not have resistance. In order to overcome the problems of short fire resistance, excellent weather resistance and high decorative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

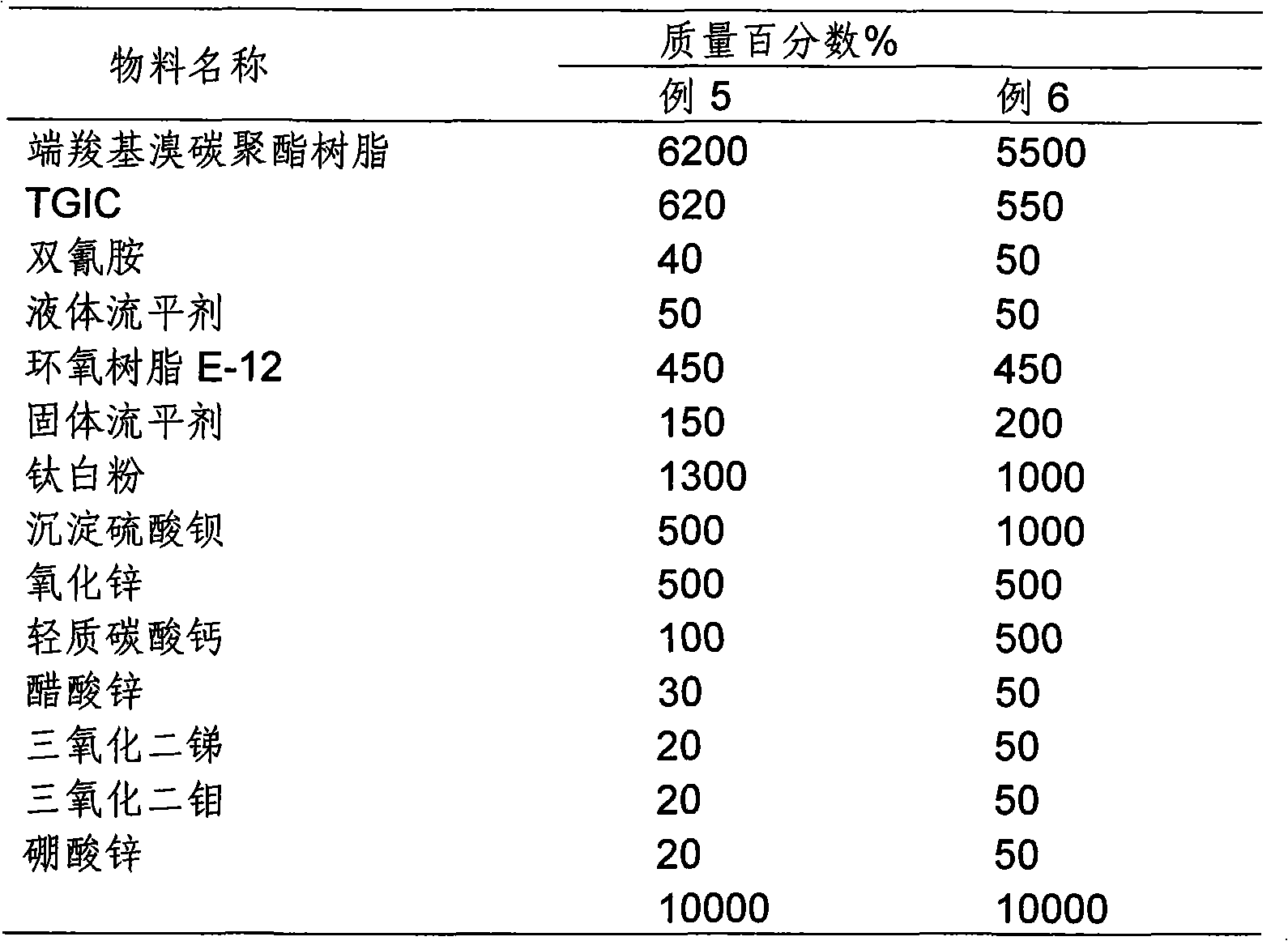

[0052] The preparation method of bromocarbon-containing polyester powder fireproof coating of the present invention, carries out batching according to above-mentioned prescription, and its preparation steps are:

[0053] a. Mix the epoxy resin E-12 and the liquid leveling agent at high speed for 3 to 5 minutes to obtain the loaded liquid leveling agent;

[0054] b. Mix carboxy-terminated bromocarbon polyester resin, solid leveling agent and load liquid leveling agent, add curing agent, dicyandiamide, titanium dioxide, precipitated barium sulfate, zinc oxide, light calcium carbonate, zinc acetate, Antimony trioxide, molybdenum trioxide and zinc borate are mixed;

[0055] c. Add the above mixed material into the extruder to melt and extrude to obtain the molten material. The temperature of the feeding section is 85-95°C, the temperature of the melting section is 95-105°C, the temperature of the mixing section is 105-120°C, and the temperature of the discharging section is 100~1...

Embodiment 1

[0064] This embodiment is the preparation method of the carboxyl-terminated bromocarbon polyester resin of the present invention.

[0065]a. Add 2000g of dimethyl terephthalate, 950g of ethylene glycol, 750g of neopentyl glycol and 5g of zinc acetate into a reaction flask with fractionating column, stirring, thermometer and inert gas inlet, slowly heat and melt the material, and the material After melting, start stirring, pass inert gas, and react at 150°C to 210°C until 800ml of methanol is released.

[0066] b. Slowly raise the temperature to 230°C to remove 400ml of ethylene glycol, cool down to 200°C, add 750g of tetrabromophthalic anhydride and 140g of adipic acid, raise the temperature to 240°C for esterification, and dehydrate 125ml.

[0067] c. Stop passing the inert gas, add 5g of antimony trioxide, control the pressure reduction polymerization temperature below 240°C, vacuum degree of 15mmHg, react for 1.5h, and take samples to measure the softening point of 110°C. ...

Embodiment 2~3

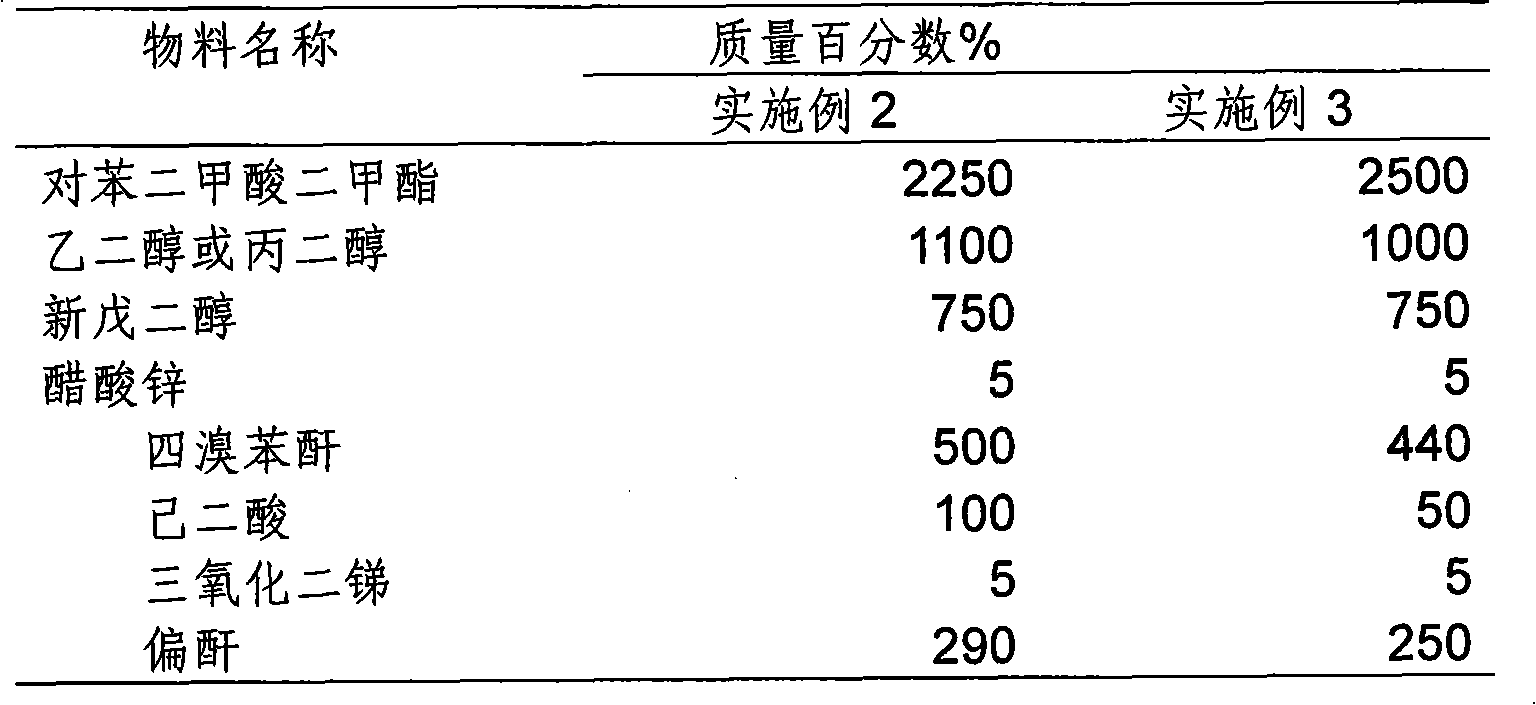

[0070] The formula of carboxyl-terminated bromocarbon polyester resin is as shown in table 1, and others are identical with embodiment 1.

[0071] Table 1. Formulation of carboxyl-terminated bromocarbon polyester resin

[0072]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com