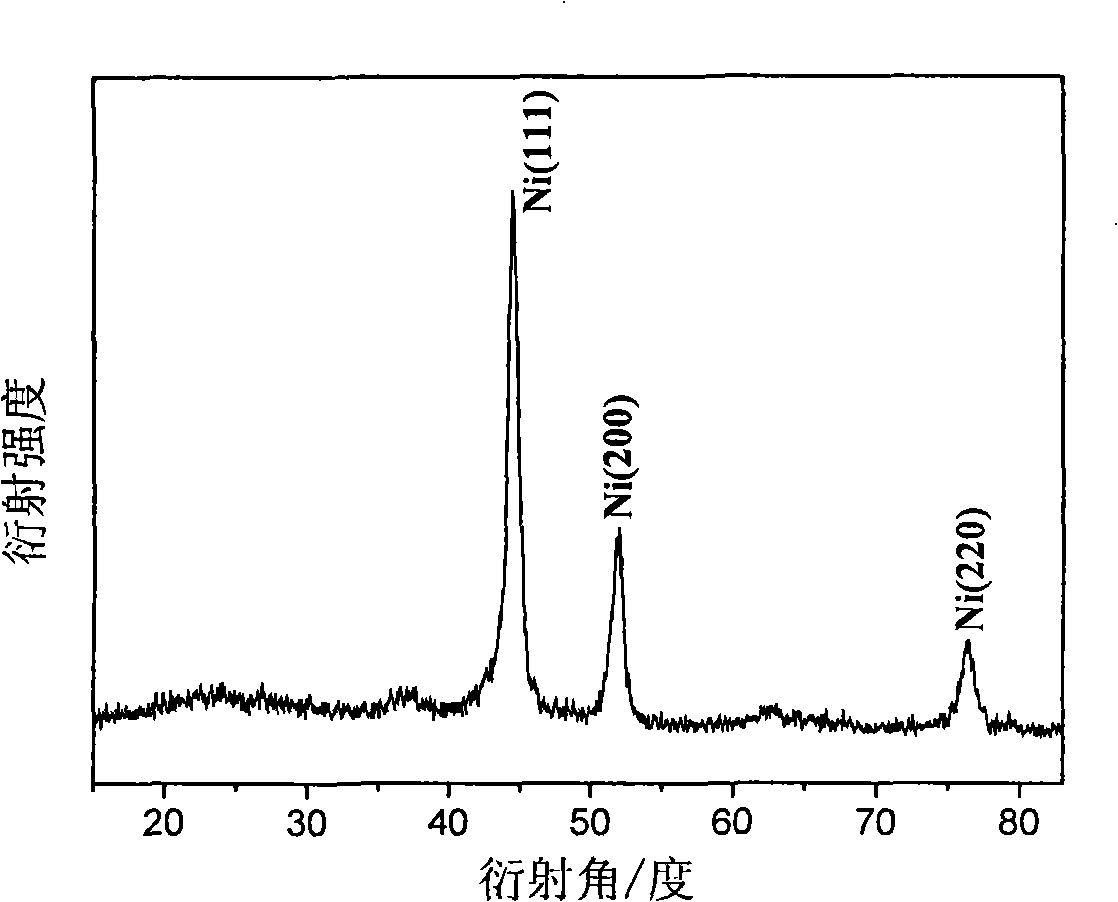

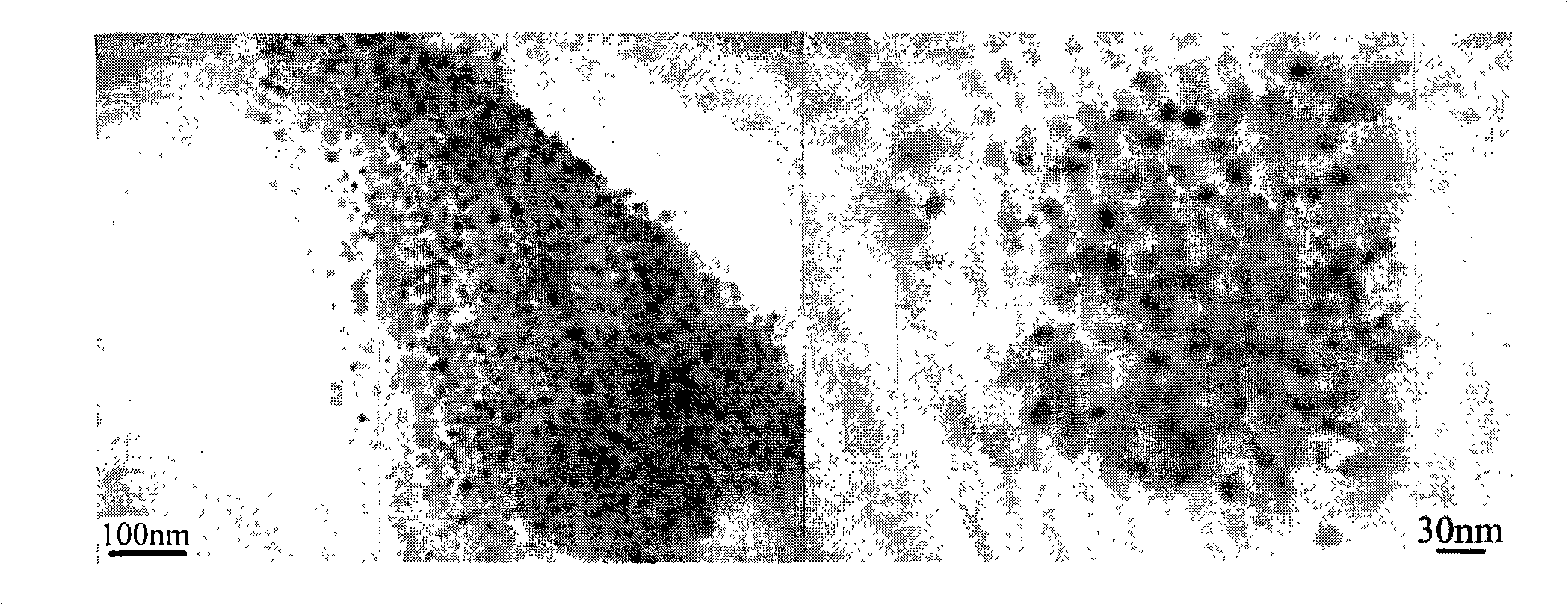

High dispersion metal nano granule and preparation thereof

A technology of metal nanoparticles and high dispersion, applied in the field of metal nickel, cobalt nanoparticles and their preparation, can solve the problems of poor thermal stability and high cost of raw materials, and achieve narrow size distribution, lower production costs, and cheap and easy-to-obtain raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 2.3256g Ni(NO 3 ) 2 ·6H 2 O and 1.5006g Al(NO 3 ) 3 9H 2 O was added to 40ml deionized water to prepare a mixed salt solution, in which Ni 2+ The molar concentration is 0.2mol L -1 , Al 3+ The molar concentration is 0.1mol L -1; Prepare 40 milliliters of mixed alkaline solutions with 0.768g sodium hydroxide and 0.848g anhydrous sodium carbonate, wherein the sodium hydroxide molar concentration is 0.48mol L -1 , the concentration of anhydrous sodium carbonate is 0.2mol L -1 .

[0023] Quickly pour the prepared mixed salt solution and mixed alkali solution into the fully back-mixed liquid membrane reactor at room temperature and mix them, vigorously rotate and stir for 2 minutes, centrifuge the obtained suspension, and run it at 4000 rpm for 5 minutes , and washed 5 times with water to obtain a precipitate.

[0024] Dissolve 5.400g of glucose into 40ml of deionized water to prepare a solution, mix the obtained precipitate with the glucose solution, pour it into...

Embodiment 2

[0026] 4.2785g NiCl 2 ·6H 2 O and 1.4485g AlCl 3 ·6H 2 O was added to 30ml deionized water to prepare a mixed salt solution, in which Ni 2+ The molar concentration is 0.6mol L -1 , Al 3+ The molar concentration is 0.2mol L -1 30 milliliters of mixed alkaline solutions are prepared with 1.536g sodium hydroxide and 0.7013g sodium chloride, wherein the molar concentration of sodium hydroxide is 1.28molL -1 , the concentration of sodium chloride is 0.4mol L -1 .

[0027] Quickly pour the prepared mixed salt solution and mixed alkali solution into the fully back-mixed liquid membrane reactor at room temperature to mix, vigorously rotate and stir for 3 minutes, and centrifuge the obtained suspension (4000 rpm, 5 minutes each time)-wash with water After 4 cycles, a precipitate was obtained.

[0028] Dissolve 12.3228g of sucrose into 30ml of deionized water to prepare a solution, mix the prepared precipitate with the sucrose solution, pour it into the reaction kettle, add wat...

Embodiment 3

[0030] 10.5142g NiSO 4 ·6H 2 O and 7.5026g Al(NO 3 ) 3 9H 2 O was added to 50ml deionized water to prepare a mixed salt solution, in which Ni 2+ The molar concentration is 0.8mol L -1 , Al 3+ The molar concentration is 0.4mol L -1 50 milliliters of mixed alkaline solutions are prepared with 3.840g sodium hydroxide and 4.2620g sodium sulfate, wherein the sodium hydroxide molar concentration is 1.92mol L -1 , the concentration of sodium sulfate is 0.6mol L -1 .

[0031] Quickly pour the prepared mixed salt solution and mixed alkali solution into the fully back-mixed liquid membrane reactor at room temperature to mix, vigorously rotate and stir for 3 minutes, and centrifuge the obtained suspension (4000 rpm, 5 minutes each time)-wash with water After 4 cycles, a precipitate was obtained.

[0032] Dissolve 28.800g of glucose into 50ml of deionized water to prepare a solution, mix the prepared precipitate with the glucose solution, pour it into the reaction kettle, add wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com