Microcrystalline glass for precipitating La2O3 nano-crystalline and preparation method thereof

A technology of glass-ceramics and nano-crystals, which is applied in the field of glass-ceramics and its preparation, can solve the problems of poor chemical stability and mechanical strength, high phonon energy of the glass matrix, and reduced luminous efficiency, and achieve low production costs and high luminous efficiency. Effects of intensity enhancement and high fluorescence lifetime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: Table 1 is the glass-ceramic formula and crystallization temperature value of embodiment 1.

[0027] Table 1

[0028]

[0029] Concrete preparation process is as follows:

[0030] In the first step, weigh each component according to the formula in Table 1, mix the above components evenly and pour them into a quartz crucible for melting at a melting temperature of 1400°C, keep the temperature for 2 hours, pour the glass melt into a cast iron mold, Then place it in a muffle furnace for annealing, keep it at the glass transition temperature for 1 hour, turn off the power of the muffle furnace and cool it down to room temperature naturally, and take out the glass;

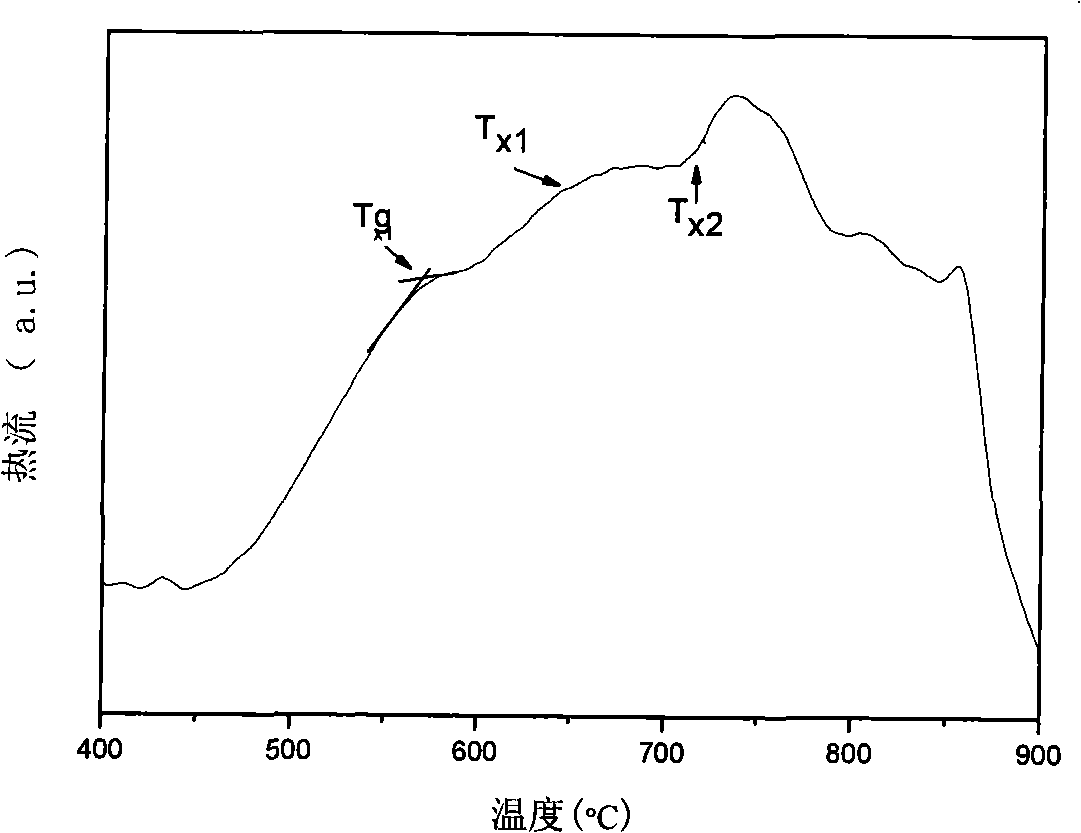

[0031] In the second step, according to the thermal analysis (DTA) experimental data of glass (see figure 1 ) to obtain the second crystallization temperature Tx 2 It is 710°C. The prepared glass was placed in a muffle furnace for heat treatment at 710°C for 2 hours, and then the power of th...

Embodiment 2

[0034] Embodiment 2: Table 2 is the glass-ceramic formula and crystallization temperature value of embodiment 2.

[0035] Table 2

[0036]

[0037] Concrete preparation process is as follows:

[0038] In the first step, weigh each component according to the formula in Table 2, mix the above components evenly and pour them into a quartz crucible to melt at a melting temperature of 1400°C, keep it warm for 1 hour, pour the glass melt into a cast iron mold, Then place it in a muffle furnace for annealing, keep it at the glass transition temperature for 1 hour, turn off the power of the muffle furnace and cool it down to room temperature naturally, and take out the glass;

[0039] The second step is to obtain the second crystallization temperature Tx according to the thermal analysis (DTA) experimental data of the glass 2 It is 720°C. The prepared glass was placed in a muffle furnace for heat treatment at 720°C for 1 hour, and then the power of the muffle furnace was turned ...

Embodiment 4

[0047] Embodiment 4: Table 4 is the glass-ceramic formula and crystallization temperature value of embodiment 4.

[0048] Table 4

[0049]

[0050] Concrete preparation process is as follows:

[0051] In the first step, weigh each component according to the formula in Table 4, mix the above components evenly and pour them into a quartz crucible to melt at a melting temperature of 1500°C, keep it warm for 1 hour, pour the glass melt into a cast iron mold, Then place it in a muffle furnace for annealing, keep it at the glass transition temperature for 1 hour, turn off the power of the muffle furnace and cool it down to room temperature naturally, and take out the glass;

[0052] In the second step, according to the glass thermal analysis (DTA) experimental data, the second crystallization temperature is 770°C. The prepared glass was heat-treated in a muffle furnace at 770°C for 6 hours, and then the power of the muffle furnace was turned off to cool down to room temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com