Pyroelectric lithium tantalite LiTa3O8 thin film and preparation technique thereof

A lithium tantalate and a preparation process technology are applied in the field of pyroelectric lithium tantalate LiTa3O8 thin film and its preparation, which can solve the problems of high manufacturing cost of detectors, complex system structure and the like, achieve low equipment and manufacturing costs, and solve crystallization problems. High temperature, good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

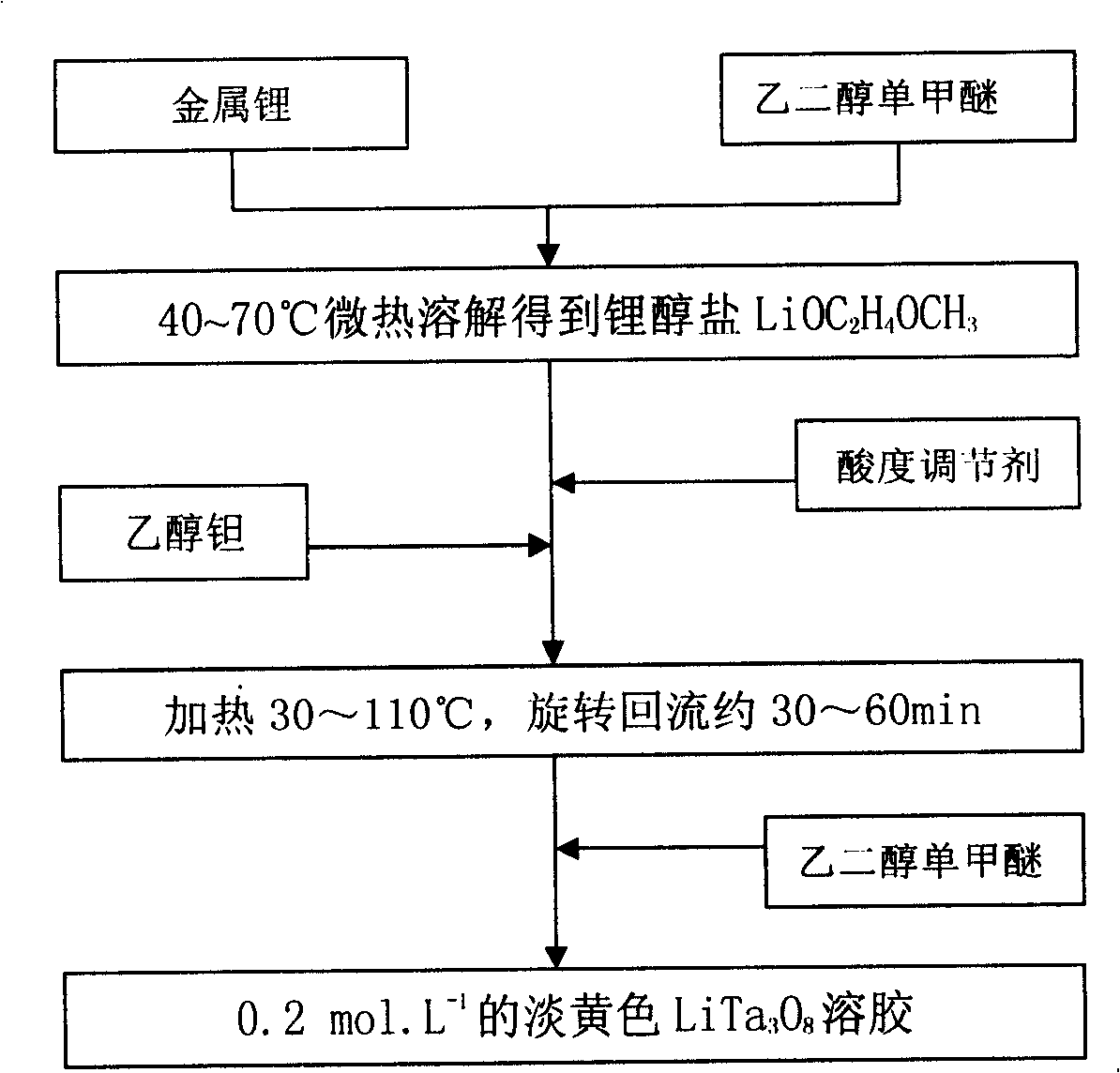

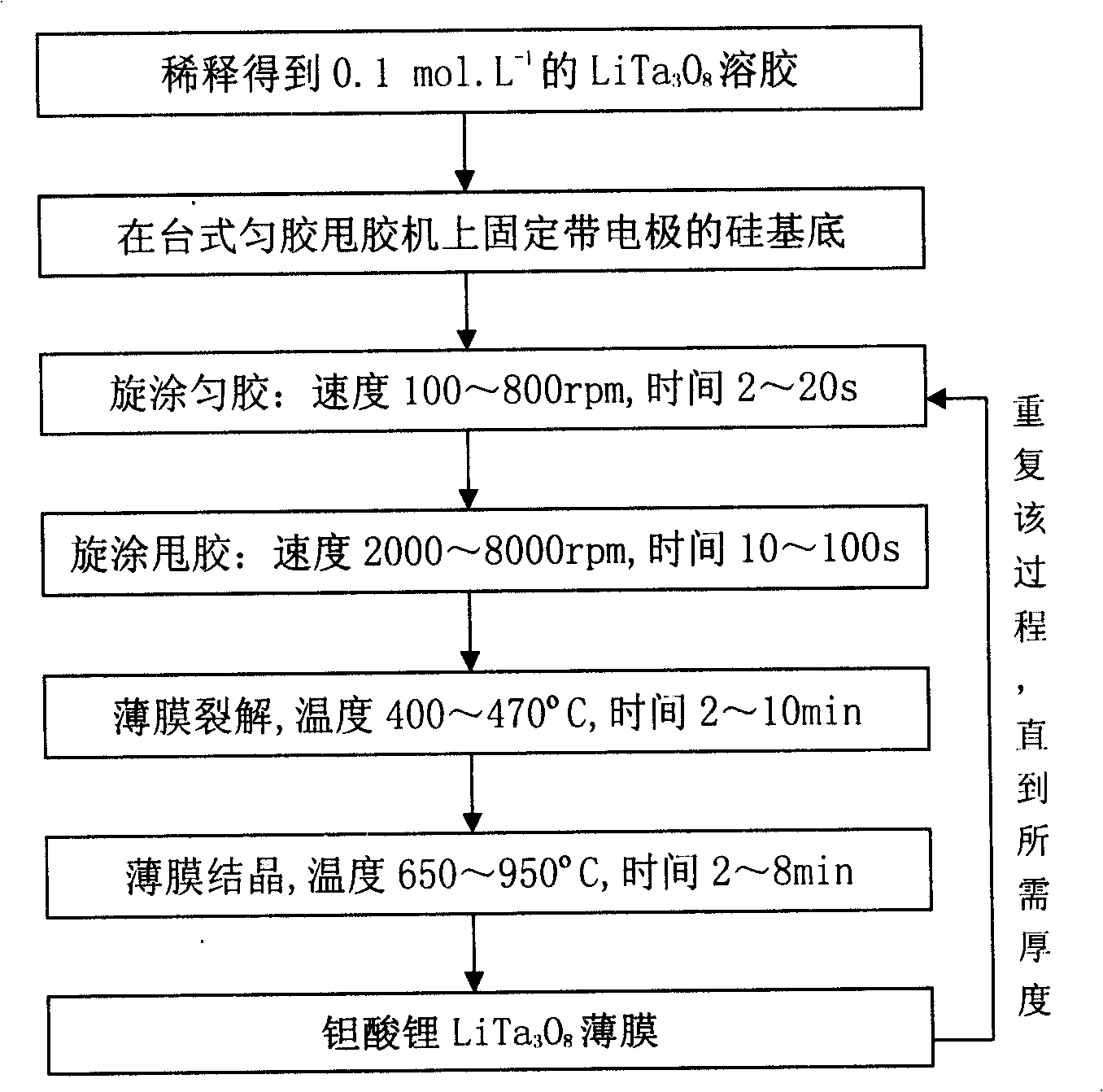

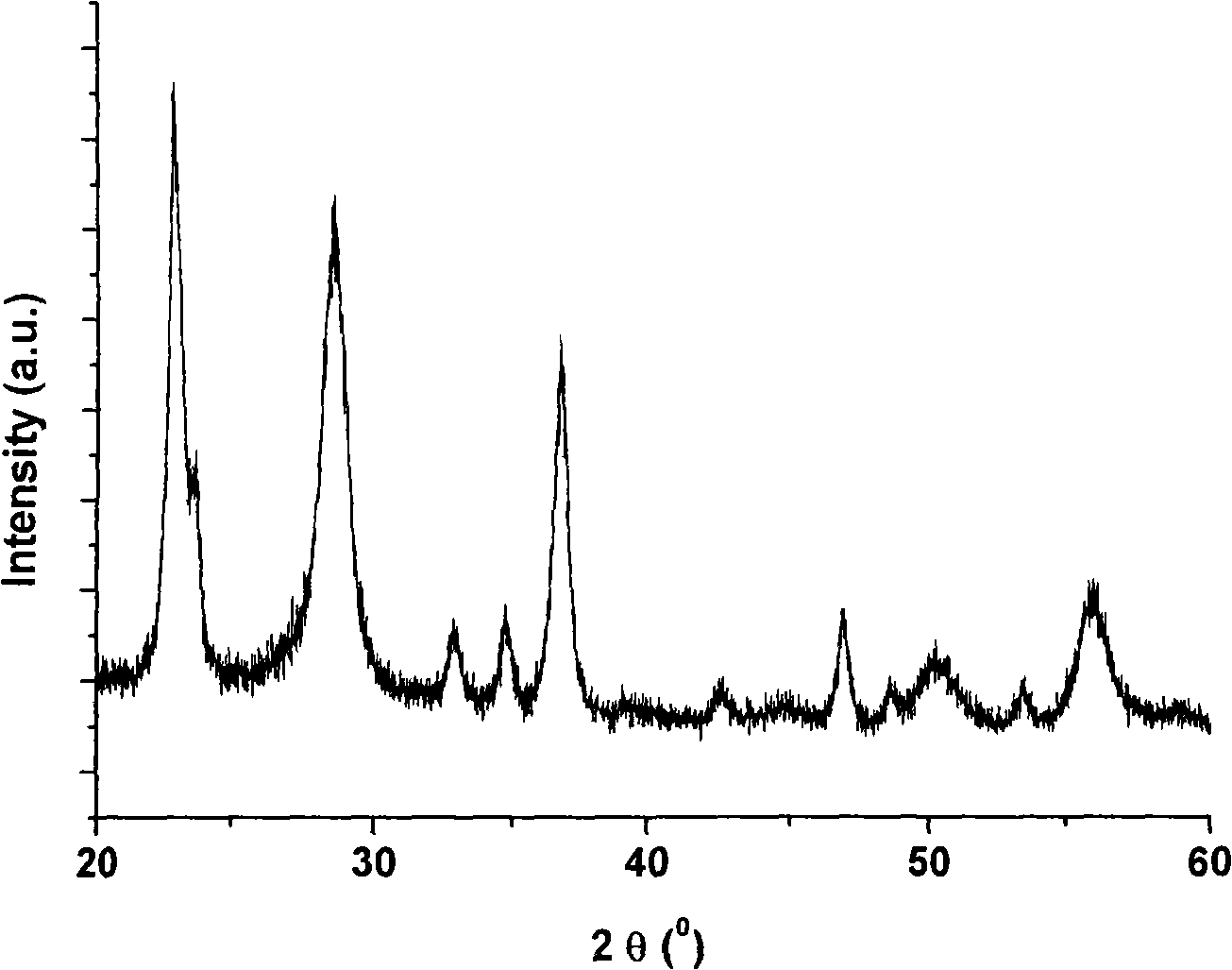

[0025] Using high-purity metal lithium and tantalum ethoxide as raw materials, using analytically pure ethylene glycol methyl ether as a solvent, LiTa was prepared under the protection of an argon atmosphere. 3 o 8 Sol, diluted with ethylene glycol monomethyl ether to a concentration of 0.1mol.L -1 , the sol was spin-coated on Pt / Ti / SiO 2 / Si(100) substrate, a wet film is formed, and the wet film is placed in a rapid heat treatment furnace for annealing and crystallization in an oxygen atmosphere. Repeat the above process to prepare amorphous LiTa with the required thickness 3 o 8 thin film, its X-ray diffraction curve is as follows image 3 shown. Scanning electron microscope SEM test found that the film is flat, uniform, no cracks, and Pt / Ti / SiO 2 / Si(100) substrate is well bonded, and the film thickness is about 1 μm, as shown in Figure 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com