Method for rapid determination for minim antimony of steel

A rapid determination and micro-quantity technology, applied in the preparation of test samples, electrical excitation analysis, material excitation analysis, etc., can solve the problems of uneven sample injection, high detection limit of analysis, and large fluctuation of spectral line intensity, etc., to achieve Effects of improving assay sensitivity, optimizing assay conditions, and enlarging test range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

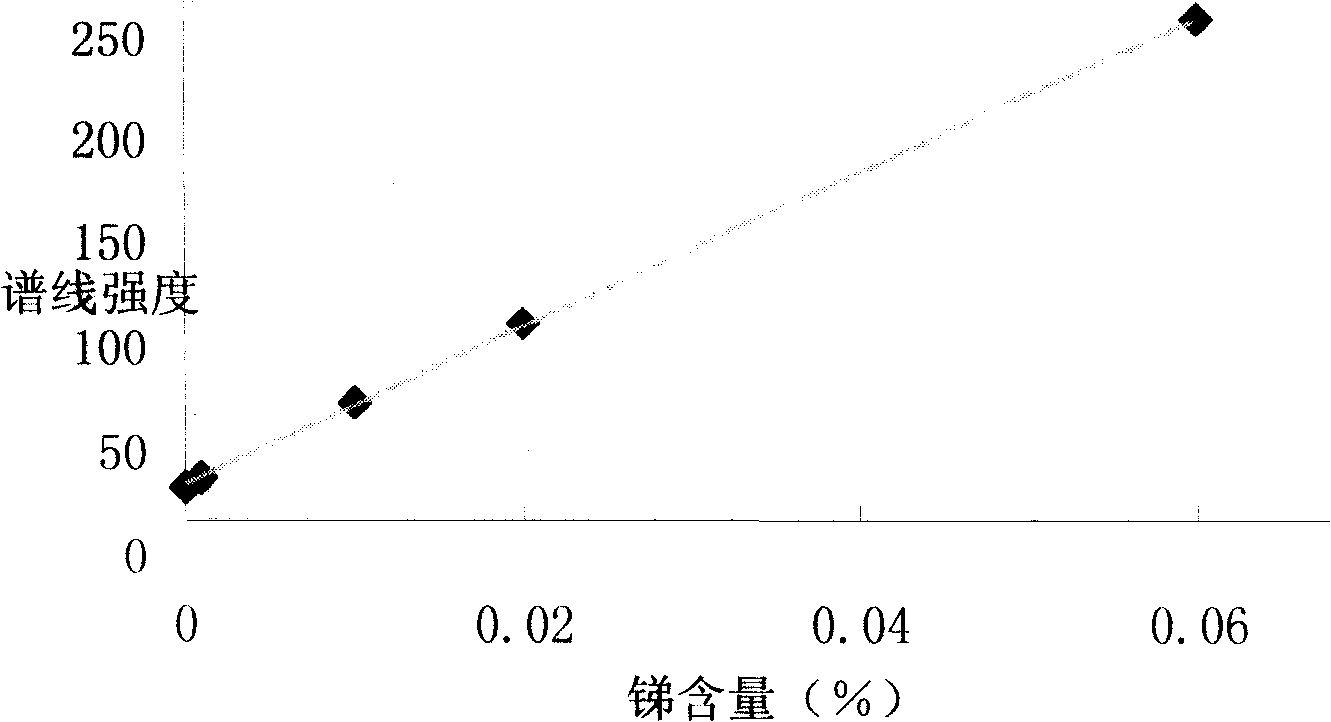

[0032] Embodiment 1 mixed interference test

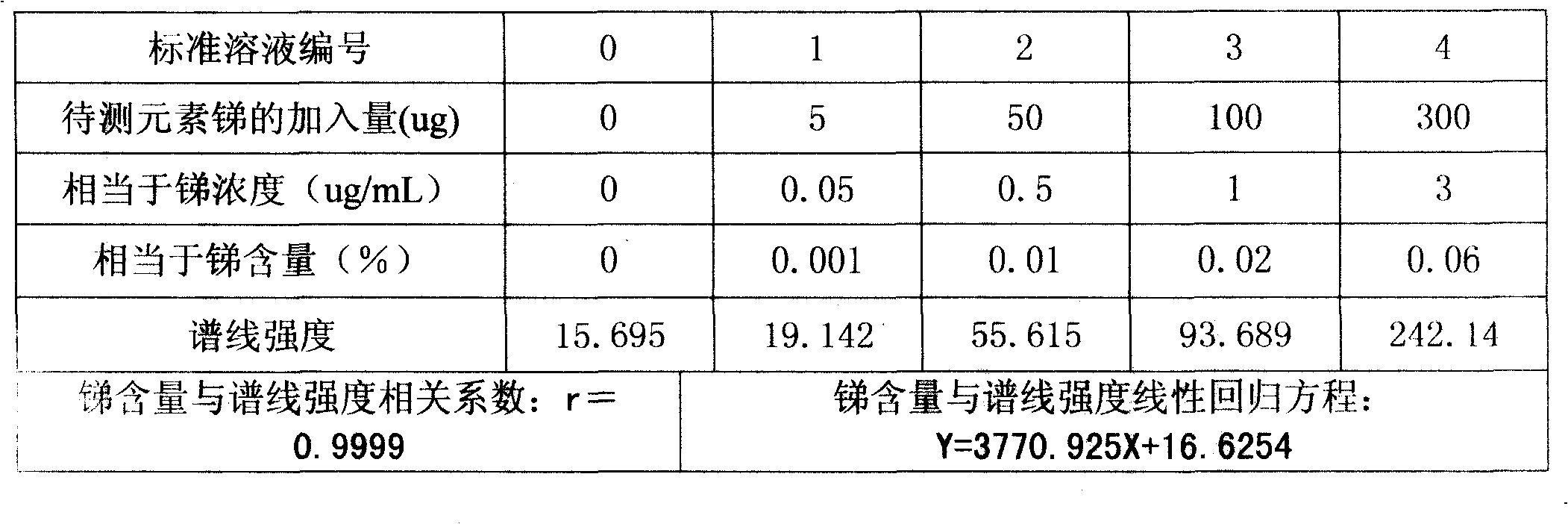

[0033] Matrix Fe interferes with antimony. The standard curve of the mixed interference test invented is based on 4-6mg / mL iron as the matrix, 40-60mL mixed acid as the medium, the antimony content of the added standard solution is 0ug, 5ug, 50ug, 100ug, 300ug, and the volume is 100mL. The data are shown in Table 1, attached figure 1 ,Table 2. The amount of antimony added in the interference test is equivalent to 0.01% by mass of antimony.

Embodiment 2

[0034] Embodiment 2 determines the linear relationship between the spectral line intensity of the antimony standard concentration solution and the working curve

[0035] Detection limit test: Carry out ten consecutive measurements on the blank sample, and multiply the average value of the standard deviation (SD) of 10 tests by three to obtain a detection limit of 0.0000991% (0.004955ug / mL), which is lower than << The detection limit of antimony described in the paper "ICP-AES Determination of As, Sn, Pb, Sb, Bi in ordinary carbon steel and low alloy steel" in Metallurgical Analysis (Volume 25, Issue 2) is 0.0073ug / mL .

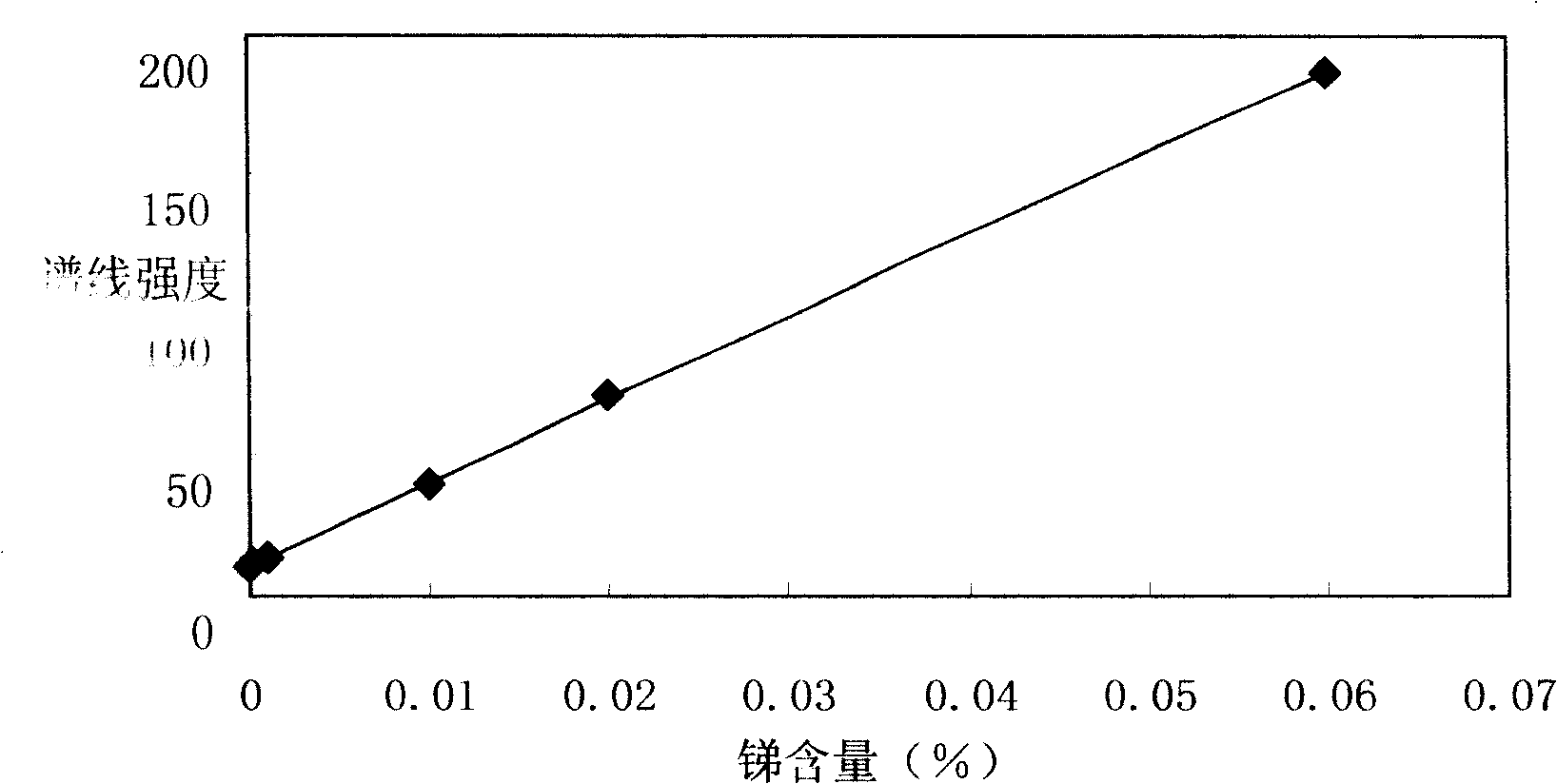

[0036] The linear relationship of the working curve: Weigh six parts of 0.4-0.6000g high-purity iron into a 250mL beaker, dissolve with 40-60mL mixed acid (HCl:HNO3:H2O=1:2:7), remove, cool, and transfer to a 100mL volumetric flask , add 0ug, 5ug, 50ug, 100ug, 300ug of antimony respectively, dilute to the mark with high-purity water, and shake well. Under th...

Embodiment 3

[0041] Weigh six parts of 0.4900g high-purity iron into 250mL beakers respectively, and use 45mL mixed acid (HCl:HNO 3 :H 2 (0=1:2:7) dissolves, removes, cools, transfers into 100mL volumetric flask, adds the antimony of corresponding content respectively according to accompanying drawing 3, dilutes to scale with high-purity water, shakes up. Under the selected working conditions of the instrument, measure its intensity value to antimony standard solution, and carry out linear regression calculation, the results are shown in Table 4 and attached figure 2 .

[0042] Weigh 0.4850g sample 1 in a 250mL Erlenmeyer flask, add 45mL mixed acid (HCl: HNO 3 :H 2 (0=1: 2: 7), low-temperature heating to dissolve the sample, after the dissolution is complete, remove it, cool it, transfer it into a 100mL volumetric flask, and analyze its antimony content to be 0.0017%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com