Method and device for blowing breeze to pure oxygen smelting mobile filling bed smelting furnace

A moving packed bed and smelting furnace technology, which is applied in the combustion method, the use of multiple fuel combustion, and the burner for burning powder fuel, etc. The problem of large volume and weight of the device can achieve the effect of good cooling effect, light weight and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

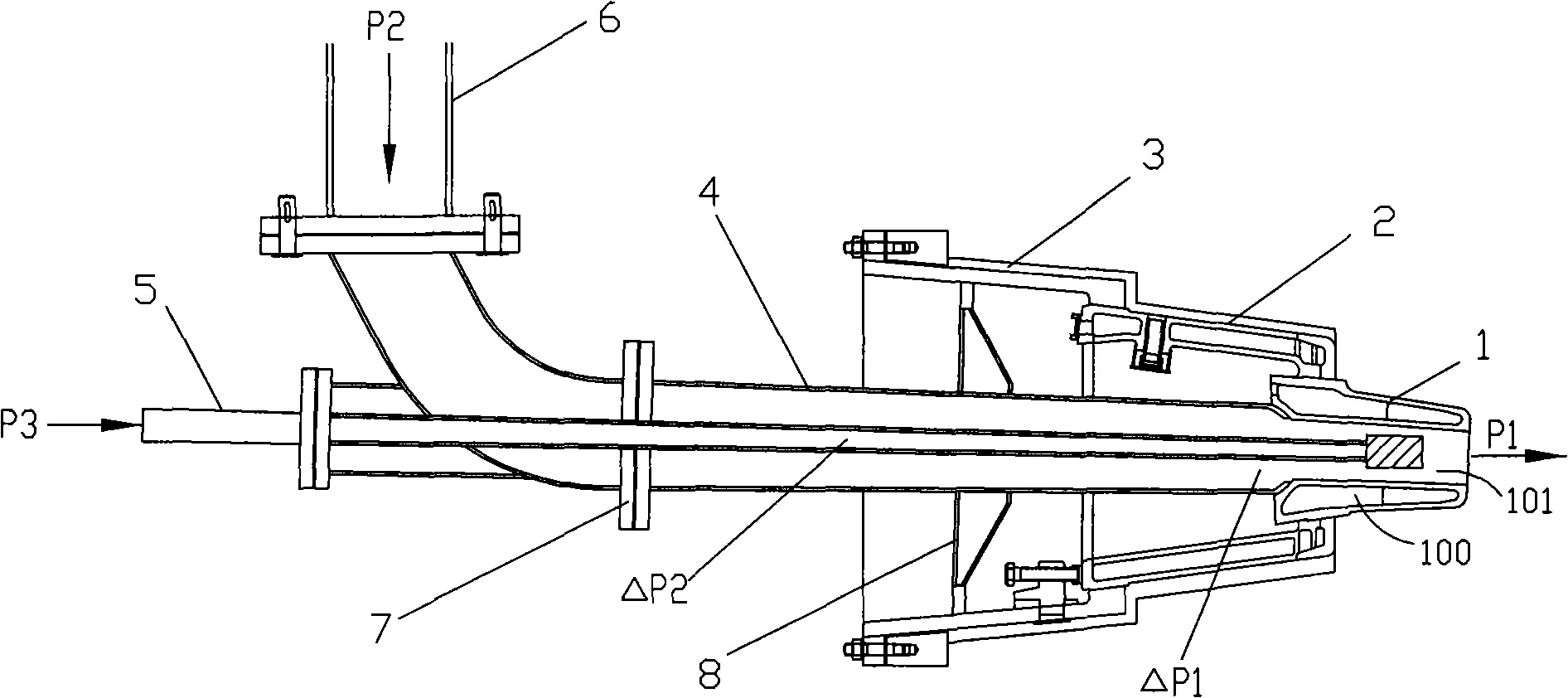

Embodiment 1

[0029] The melting gasifier of the COREX smelting reduction unit belongs to a pure oxygen injection moving packed bed smelting furnace. Its hearth is equipped with multiple oxygen water-cooled air outlets. The oxygen air outlet is composed of a small tuyere sleeve, a large tuyere sleeve and an oxygen lance. According to the present invention, the coal injection device is mainly composed of three parts: a small water-cooled air outlet, an oxygen direct blowing pipe, and a coal injection gun. The water-cooled air outlet is a multi-channel copper water-cooled air outlet, which is connected with the oxygen blowing header and the water-cooled air outlet at both ends by an oxygen direct blowing pipe. The inner diameter of the water-cooled air outlet and the oxygen direct blowing pipe are equal or close.

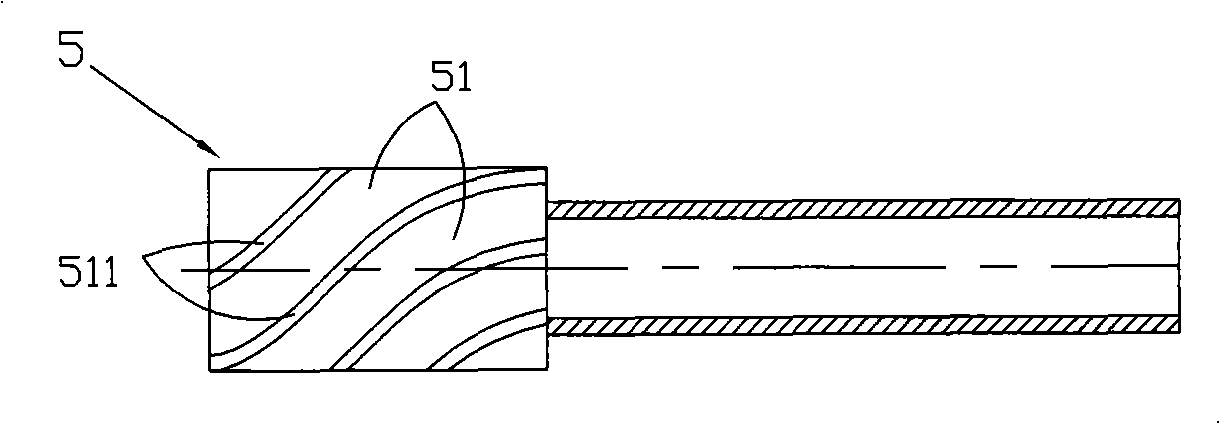

[0030] The coal injection gun is a coaxial circular steel pipe with the tuyere and the oxygen direct blowing pipe, which is located in the center of the tuyere and the oxygen direct bl...

Embodiment 2

[0034] The ferrochrome shaft furnace device belongs to a mobile packed bed smelting furnace that can be sprayed with pure oxygen, including raw fuel transportation, ore troughs, inclined bridges, furnace roof, furnace body, pulverized coal injection, iron casting yard, tuyere platform, hot air Furnace, slag treatment, gas dust removal and other facilities. An internal volume of 200m 3 1 shaft furnace; annual output of 100,000 tons of chromium alloy hot metal; 93,000 tons of water slag: the design top pressure of the shaft furnace is 0.15Mpa. The main raw materials for shaft furnace smelting are the pre-reduced ferrochrome pellets in the rotary hearth furnace (the metallization rate of iron and chromium in the pellets can reach about 75% and 35%) and concentrated ore, and pre-reduced ferrochrome pellets The amount of iron fed into the furnace is about 1650kg, and the amount of concentrated ore into the furnace is about 240kg.

[0035] The shaft furnace hearth is equipped with 10 ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com