Method for oxidizing and denitrating ozone containing industrial waste gas HCl

A technology for industrial waste gas and ozone oxidation, which is applied to chemical instruments and methods, separation methods, and separation of dispersed particles, can solve the problems of large investment, high operating costs, and low reaction temperature, and achieve low investment, low operating costs, and high efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

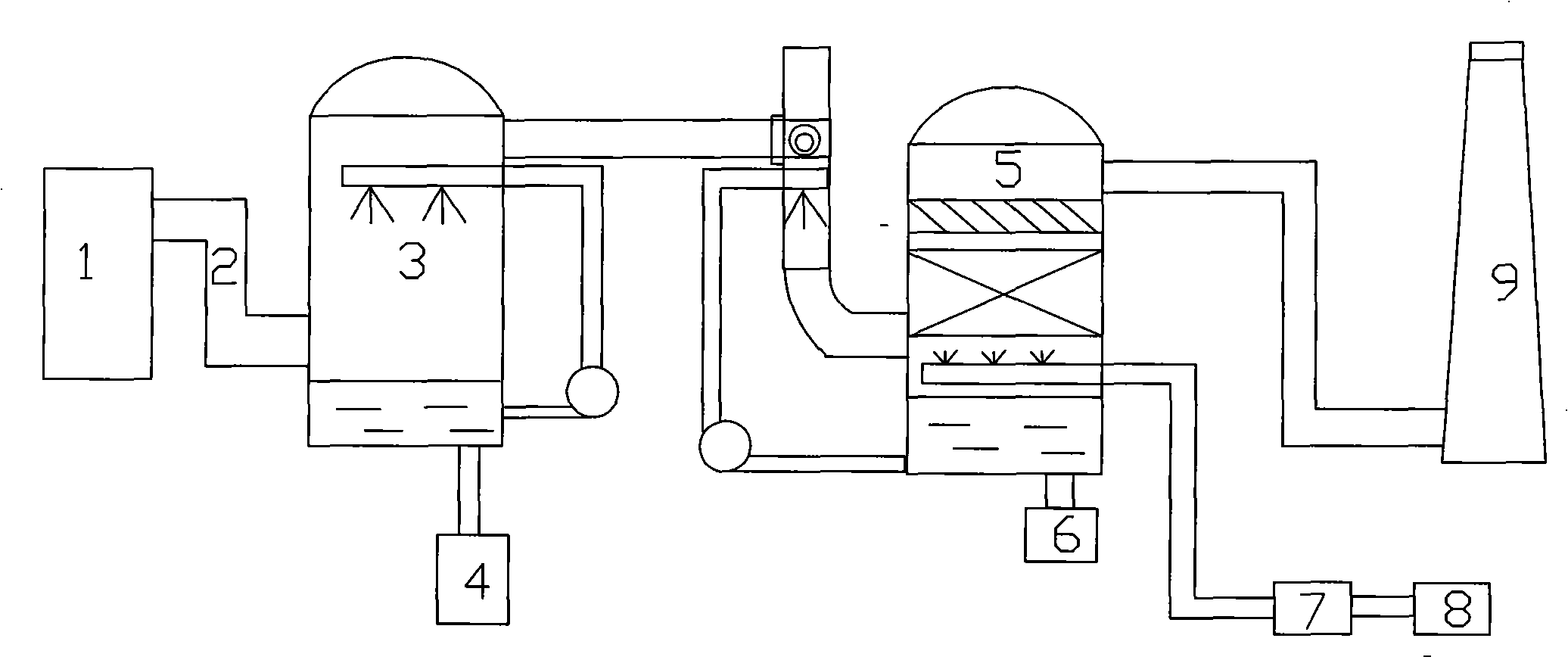

[0025] It is a process of injecting ozone oxidation into the industrial waste gas tower combined with wet scrubbing and denitrification. figure 1 .

[0026] Firstly, the industrial waste gas (10000m 3 / h, containing HCl 1×10 5 mg / m 3 , containing NO X 5×10 4 mg / m 3 ) introduce a water-washing absorption tower 3 that removes HCl through the exhaust gas delivery pipeline 2, and the spray flow rate in the water-washing absorption tower 3 is 50m 3 / h water flow, absorb the HCl in the exhaust gas into the water, produce dilute hydrochloric acid, discharge it into the dilute hydrochloric acid storage tank 4, and remove HCl gas at the same time, at the outlet of the water washing absorption tower 3, the concentration of HCl is 5 × 10 2 mg / m 3 . After the air is purified by the dryer, it is sent to the oxygen generator 7, and the oxygen produced is sent to the ozone generator 8 to prepare ozone. The ozone is injected into the oxidation absorption tower through the injector an...

Embodiment 2

[0028] It is a process of injecting ozone oxidation into the industrial waste gas tower combined with wet scrubbing and denitrification. figure 1 .

[0029] By the step of embodiment 1, at first the industrial waste gas (10000m 3 / h, containing HCl 2×10 5 mg / m 3 , containing NO X 5×10 4 mg / m 3) introduce a water-washing absorption tower 3 that removes HCl through the exhaust gas delivery pipeline 2, and the spray flow rate in the water-washing absorption tower 3 is 50m 3 / h water flow, absorb the HCl in the exhaust gas into the water, produce dilute hydrochloric acid, discharge it into the dilute hydrochloric acid storage tank 4, and remove HCl gas at the same time, at the outlet of the water washing absorption tower 3, the concentration of HCl is 6 × 10 2 mg / m 3 . After the air is purified by the dryer, it is sent to the oxygen generator 7, and the oxygen produced is sent to the ozone generator 8 to prepare ozone. The ozone is injected into the oxidation absorption t...

Embodiment 3

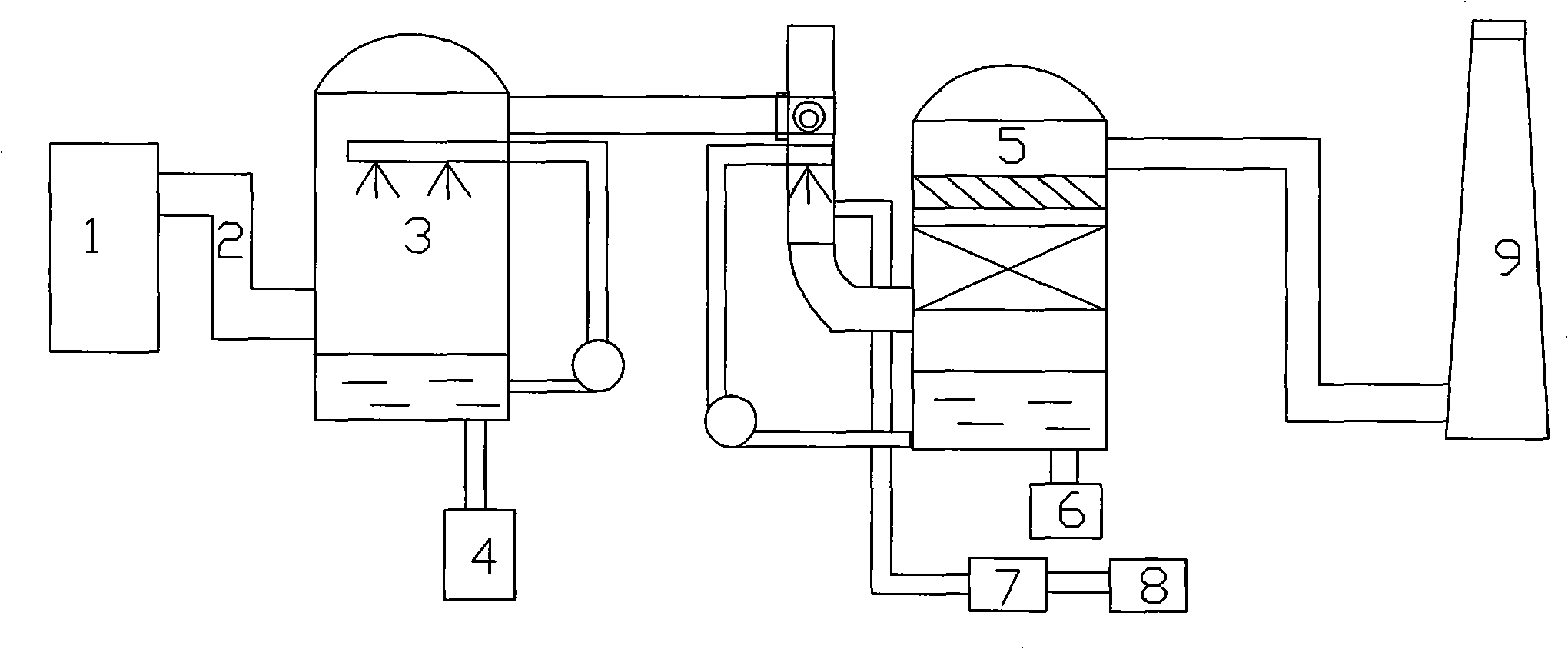

[0031] The principle of injecting ozone oxidation into the industrial waste gas pipeline combined with wet scrubbing and denitrification process is operated as follows: figure 2 .

[0032] Firstly, the industrial waste gas (5000m 3 / h, containing HCl 1×10 5 mg / m 3 , containing NO X 5×10 4 mg / m 3 , containing organic nitrogen compounds 2×10 4 mg / m 3 ) introduce a water-washing absorption tower 3 that removes HCl through the exhaust gas delivery pipeline 2, and the spray flow rate in the water-washing absorption tower 3 is 30m 3 / h water flow, absorb the HCl in the exhaust gas into the water, produce dilute hydrochloric acid, discharge it into the dilute hydrochloric acid storage tank 4, and remove HCl gas at the same time, at the outlet of the water washing absorption tower 3, the concentration of HCl is 1 × 10 2 mg / m 3 . After the air is purified by the dryer, it is sent to the oxygen generator 7, and the oxygen produced is sent to the ozone generator 8 to prepare ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com