Pd/Sn colloid catalyst adsorption enhancer

A technology of adsorption promotion and catalyst, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problems of decreased adhesion between raw materials and electroplating film, and achieve the effect of improving precipitation and good coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

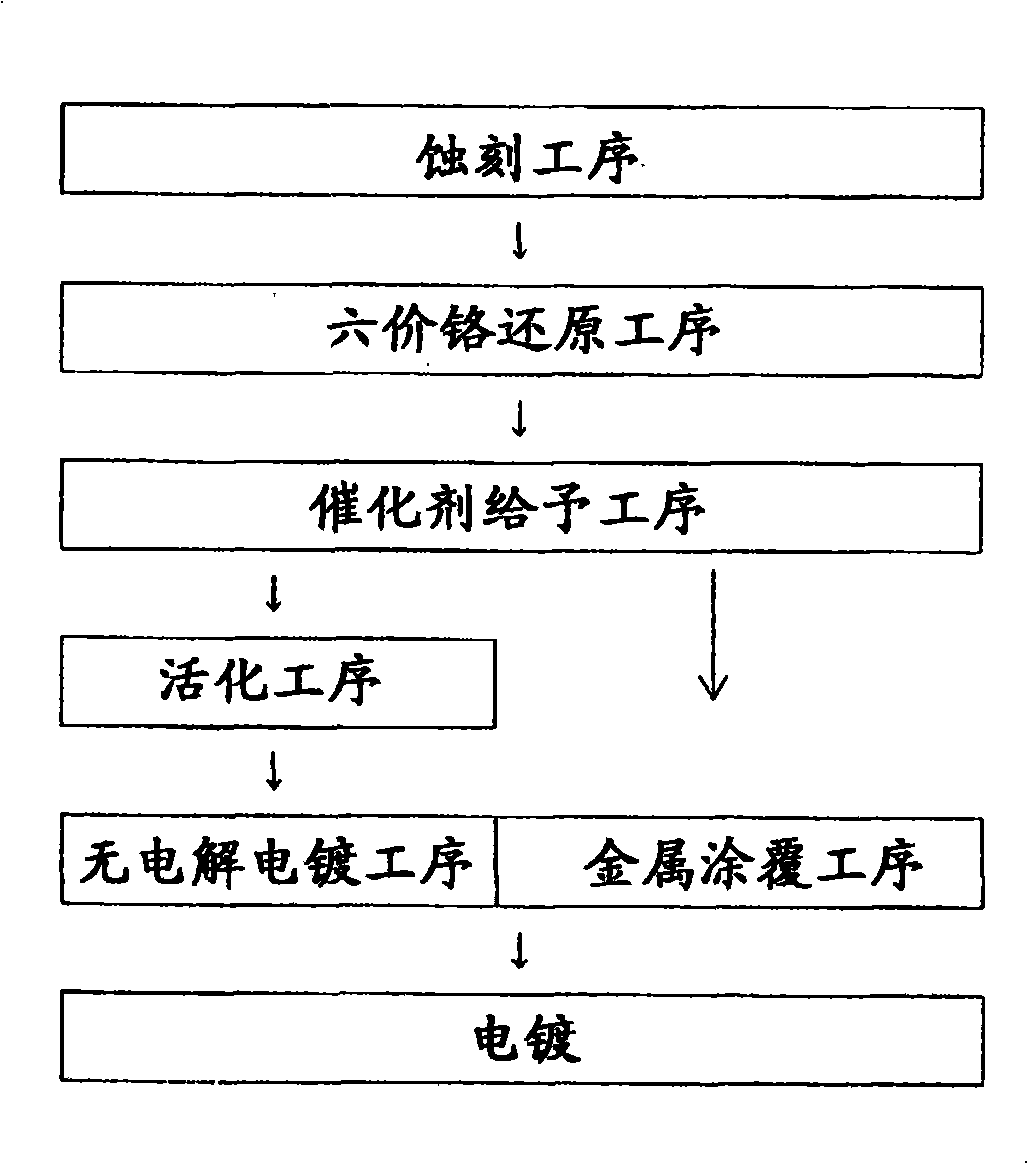

Method used

Image

Examples

Embodiment 1

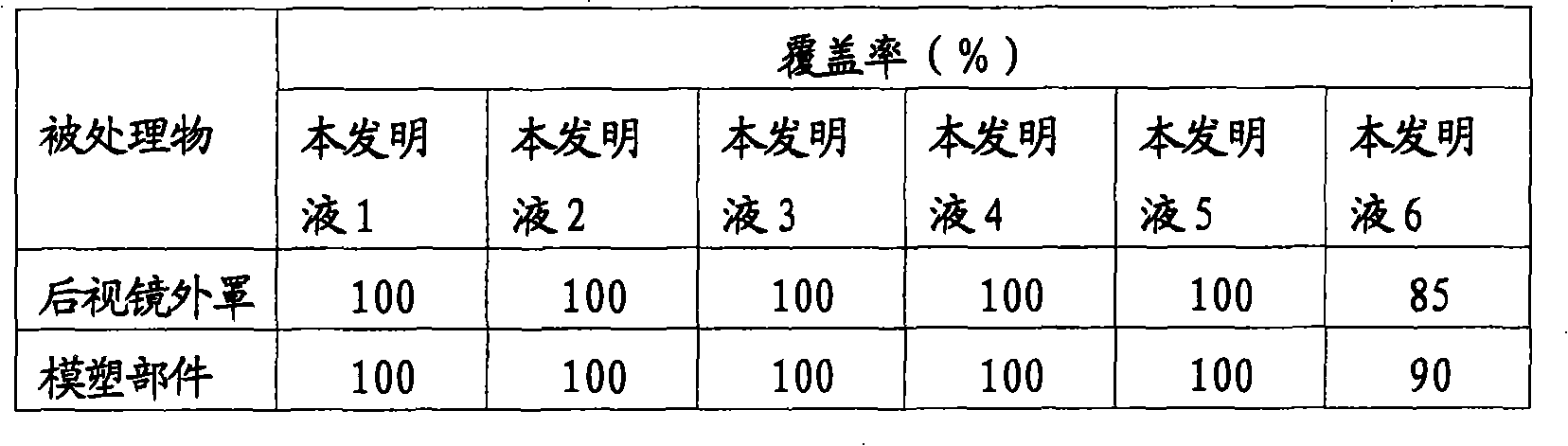

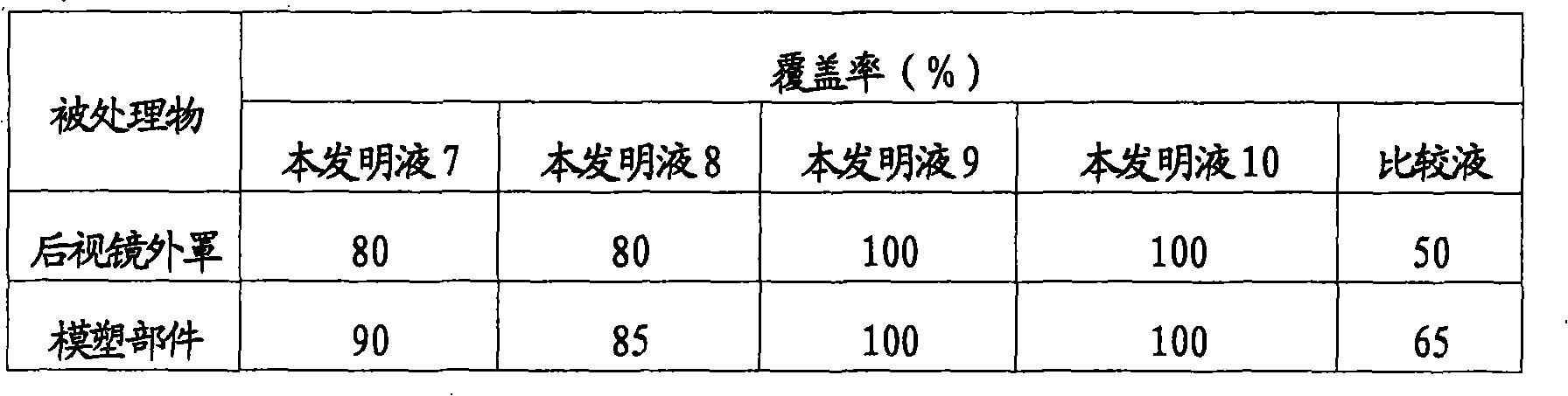

[0038] Using the solution of the present invention and the comparison solution described below, the following to-be-treated objects were subjected to catalyst imparting treatment, and the surface thereof was subjected to electroplating treatment.

[0039] (1) Objects to be processed

[0040] Processed object 1:

[0041] Adopt a surface area of about 8dm 2 ABS rearview mirror cover (mirror cover) for automobiles. A jig made of sol-baked varnish made of vinyl chloride is used as a jig for plating to support the object to be processed at three contact points.

[0042] Processed object 2:

[0043] The surface area used is about 6dm 2 ABS molded parts for automobiles. A jig for plating is used that supports the object to be processed at two contact points, and other than the contact points are made of vinyl chloride sol-baked varnish.

[0044] (2) Catalyst treatment

[0045] First, place the object fixed on the jig in an etching solution composed of an aqueous solution con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com