D-lactic acid-producing strain with high optical purity and process for producing D-lactic acid by fermentation thereof

A technology of optical purity and production of bacteria, applied in fermentation, microbial-based methods, bacteria, etc., can solve the problems of low yield, difficult operation and control, etc., and achieve simple formula, low production cost, great social significance and economic value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

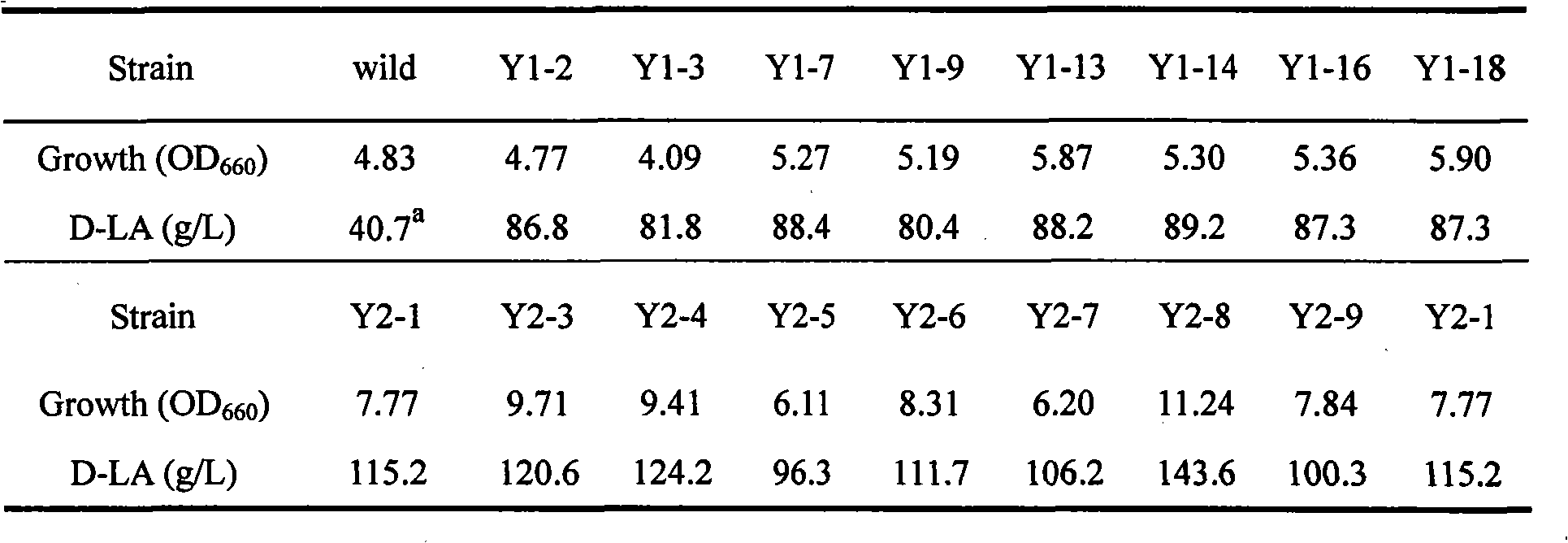

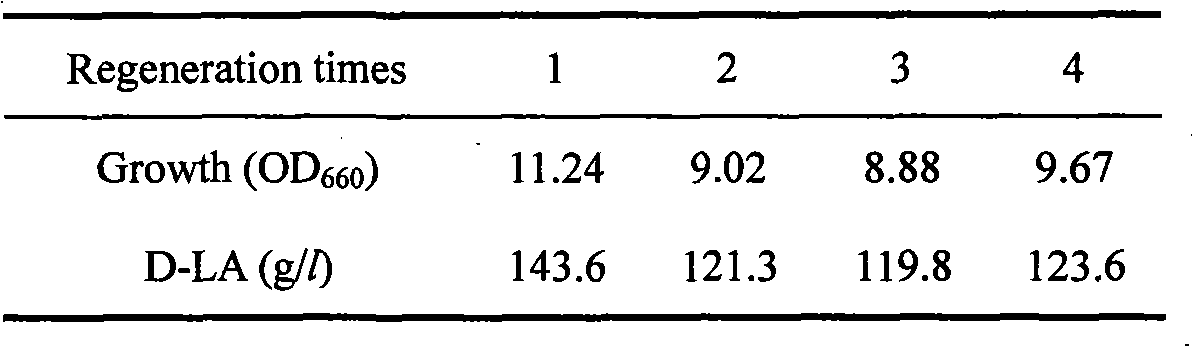

[0035] This example illustrates the breeding method of Lactobacillus sporogenes Y2-8.

[0036] 1. Screen the original strains producing D-lactic acid from the soil:

[0037] 100g / L glucose high-sugar liquid medium was used to enrich and cultivate the high-sugar-tolerant microorganisms in soil samples in Nanjing area, and then the high-sugar-tolerant microorganisms were tested under anaerobic culture conditions by 100g / L glucose-bromocresol green color development plate. The acid-producing strains were isolated, and the strains with large diameter and fast discoloration were selected for acid-producing fermentation research. The optical purity of the product is detected by high performance liquid chromatography chiral stationary phase method, the ligand exchange column model is Sumichiral CA5000, and the mobile phase is 1mM CuSO 4 solution, the UV detection wavelength is 254nm. Obtain a strain of D-lactic acid bacteria, named Sporolactobacillus inulinus DX12, cryopreserved fo...

Embodiment 2

[0049] This example illustrates the process of producing D-lactic acid by fermentation of Lactobacillus sporogenes Y2-8.

[0050] Plate medium: glucose 10%, yeast extract 0.2%, anhydrous sodium acetate 0.2%, anhydrous magnesium sulfate 0.01%, potassium dihydrogen phosphate 0.2%, agar 1.8%, water balance, pH7.0;

[0051] Seed medium: glucose 2%, yeast extract 0.3%, corn steep liquor 0.4%, bran 0.3%, anhydrous magnesium sulfate 0.02%, ferrous sulfate 0.001%, manganese sulfate 0.001%, calcium carbonate 1.5%, water balance, pH7.0;

[0052] Fermentation medium: glucose 10%, corn steep liquor 1.5%, anhydrous magnesium sulfate 0.05%, ferrous sulfate 0.001%, manganese sulfate 0.001%, water balance, pH 7.0.

[0053] Lactobacillus sporogenes Y2-8 was inoculated into the plate culture medium, placed in an anaerobic incubator for cultivation, the cultivation temperature was 30°C, and the cultivation time was 36h. Inoculate the Lactobacillus bacillus cultured on the plate into the seed m...

Embodiment 3

[0056] This example illustrates the process of producing D-lactic acid by fermentation of Lactobacillus sporogenes Y2-8.

[0057] Plate medium: glucose 12%, yeast extract 0.1%, anhydrous sodium acetate 0.3%, anhydrous magnesium sulfate 0.03%, potassium dihydrogen phosphate 0.3%, agar 1.8%, water balance, pH7.0;

[0058] Seed medium: glucose 5%, beef extract 0.6%, anhydrous magnesium sulfate 0.01%, ferrous sulfate 0.003%, manganese sulfate 0.005%, calcium carbonate 2%, water balance, pH 7.0.

[0059] Fermentation medium: corn saccharification solution (glucose meter) 10%, yeast extract 0.2%, anhydrous magnesium sulfate 0.05%, ferrous sulfate 0.001%, manganese sulfate 0.001%, water balance, pH 7.0.

[0060] Lactobacillus sporogenes Y2-8 was inoculated into the plate culture medium, placed in an anaerobic incubator for cultivation, the cultivation temperature was 37°C, and the cultivation time was 30h. Inoculate the Lactobacillus bacillus cultured on the plate into the seed medi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com