Taurolidine quality checking method

A quality inspection method, the technology of taurolidine, is applied in the direction of removing certain components such as weighing, measuring devices, material inspection products, etc., which can solve the problem of lack of inspection methods, inability to control product quality well, and insufficient inspection items. Comprehensive and other problems, to achieve the effect of convenient operation, good reproducibility, and product quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

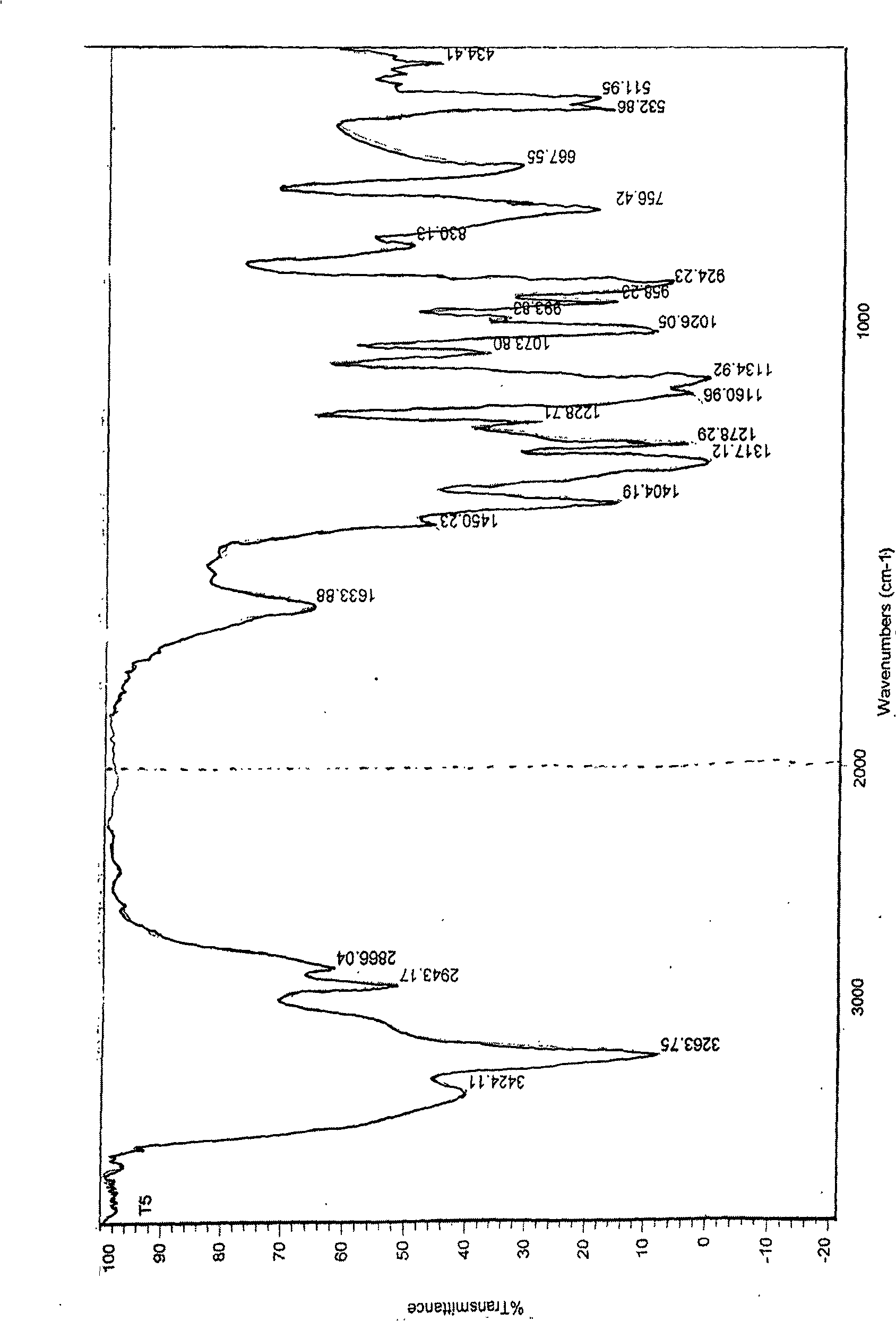

Image

Examples

Embodiment 1

[0018] Quality Research and Analysis of Taurolidine and Specific Operation Results

[0019] Appearance traits

[0020] Method: visual inspection

[0021] Check the appearance of taurolidine samples, and the results showed that the samples were all white or off-white crystalline powder; odorless.

[0022] Solubility A suitable amount of taurolidine raw material was used for solubility test with different solvents. The results are shown in Table 1.

[0023] Table 1 Taurolidine dissolution test results

[0024]

Dimethyl

Water

0.1mol / L

Hydrochloric acid solution

0.1mol / L

Liquid

Weigh the sample

(mg)

10.2

10.1

10.4

10.7

10.4

10.5

10.8

10.3

[0025]

Dissolved body

Produ...

Embodiment 2

[0056] Quality Research and Analysis of Taurolidine and Specific Operation Results

[0057] Tauramide hydrochloride: Take taurolidine and add phosphate buffer solution (pH 7.2) to make a solution containing 30mg per 1ml as the test solution; take tauramide hydrochloride reference substance and add phosphate buffer solution (pH7.2) Make a solution containing 2mg per 1ml as a reference solution. According to thin-layer chromatography (Chinese Pharmacopoeia 2005 Edition Two VB) test, draw 5μl of the test solution and 6μl of the reference solution, and place them on the same silica gel G thin-layer plate with 0.1% sodium carboxymethylcellulose as a binder. On the top, use ethyl acetate-methanol-concentrated ammonia solution (9:2:1.5) as a developing agent, unfold, dry, spray with 5% ninhydrin-acetone solution, and heat at 105°C until the spots appear clear.

[0058] Results In the chromatogram of the test substance, the impurity spots corresponding to the spots of the tauramide hydroc...

Embodiment 3

[0078] Quality Research and Analysis of Taurolidine and Specific Operation Results

[0079] Tauramide hydrochloride: Take taurolidine hydrochloride and add phosphate buffer solution (pH 7.2) to make a solution containing 10mg per 1ml as the test solution; take tauramide hydrochloride reference substance and add phosphate buffer solution (pH7.2) Make a solution containing 1mg per 1ml as a reference solution. According to thin-layer chromatography (Chinese Pharmacopoeia 2005 Edition Two VB) test, draw 15μl of the test solution and 6μl of the reference solution, and place them on the same silica gel G thin-layer plate with 0.1% sodium carboxymethylcellulose as the adhesive. On the top, use ethyl acetate-methanol-concentrated ammonia solution (9:2:1.5) as a developing agent, unfold, dry, spray with 5% ninhydrin-acetone solution, and heat at 105°C until the spots appear clear.

[0080] Results In the chromatogram of the test substance, the impurity spots corresponding to the spots of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com