Mildewproof waterproof coating composition

A technology of waterproof coatings and compositions, applied in antifouling/underwater coatings, rosin coatings, polyurea/polyurethane coatings, etc., which can solve the problems of insufficient waterproof, anti-seepage and anti-mildew properties, low tensile strength, and poor use Inconvenient and other problems, to achieve the effect of strong randomness, high tensile strength and elongation at break, and strong washing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

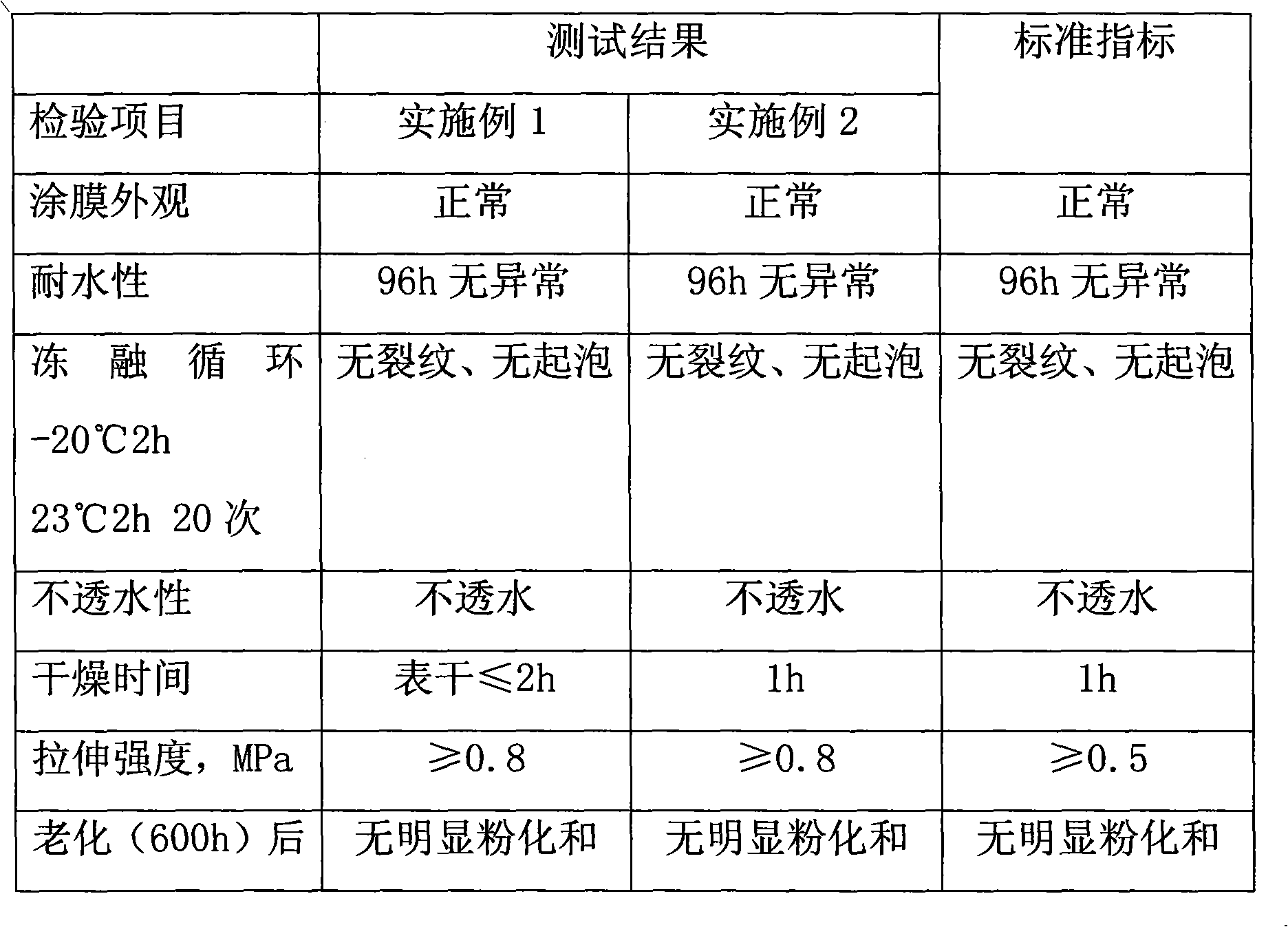

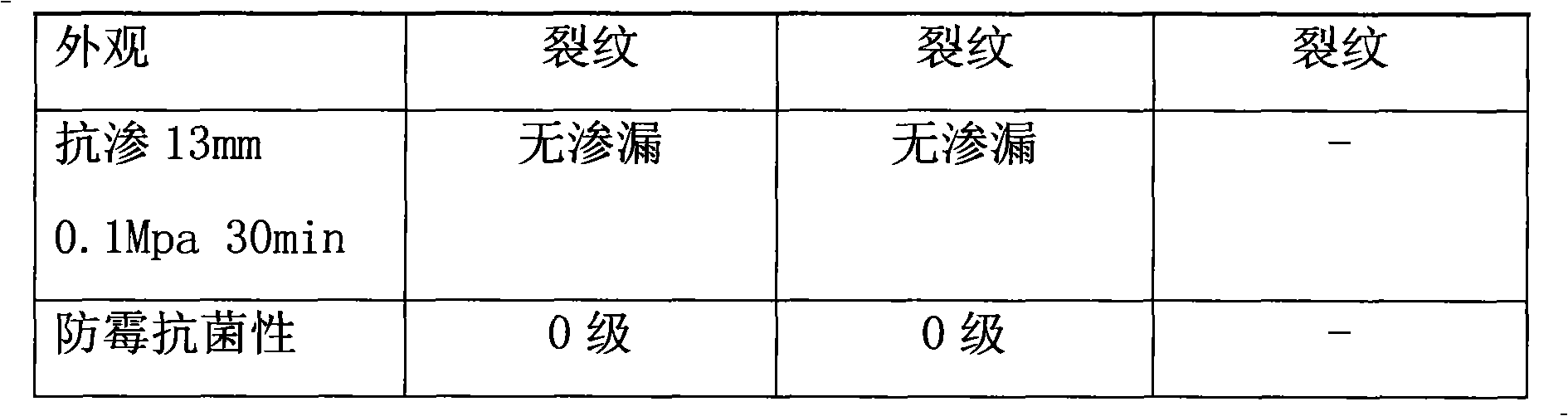

Examples

Embodiment 1

[0048] A) Preparation of polymer emulsion

[0049] In the dispersing tank, under stirring at a rotating speed of 100-400r / min, add 70 parts by weight of acrylic emulsion, 12 parts by weight of water-based polyurethane and 5 parts by weight of tall oil rosin, 3 parts by weight of propylene glycol and 10 parts by weight of water, Stir for 10 minutes to obtain a polymer emulsion.

[0050] B) Preparation of filler slurry

[0051] In a high-speed dispersing kettle, add 15 parts by weight of chromium aluminum phosphate, 2 parts by weight of KH-550, 1 part by weight of DCOIT, 2 parts by weight of magnesium aluminum silicate and 80 parts by weight of deionized water, at 500-1000r Disperse and stir at 2000-3000r / min for 30-60 minutes, then transfer it to a colloid mill for grinding at 2000-3000r / min for 1-2 hours until the fineness reaches below 10μm.

[0052] Add the prepared filler slurry into the polymer emulsion, the ratio of the polymer emulsion to the filler slurry is 10:8, and...

Embodiment 2

[0054] A) Preparation of polymer emulsion

[0055] In the dispersing tank, under stirring at 100-400r / min, add 60 parts by weight of acrylic emulsion, 10 parts by weight of water-based polyurethane and 5 parts by weight of hydrogenated rosin, 3 parts by weight of propylene glycol and 22 parts by weight of water, and stir After 10 minutes, a polymer emulsion was obtained.

[0056] B) Preparation of filler slurry

[0057] In the high-speed dispersion kettle, add 20 parts by weight of hydroxyapatite, 1 part by weight of KH-550, 1 part by weight of CIT, 2 parts by weight of magnesium aluminum silicate and 76 parts by weight of deionized water, at 500-1000r Disperse and stir at 2000-3000r / min for 30-60 minutes, then transfer it to a sand mill for grinding, and grind for 40-60 minutes at 2000-3000r / min until the fineness reaches below 30μm.

[0058] Add the prepared filler slurry into the polymer emulsion, the ratio of the polymer emulsion to the filler slurry is 10:10, and stir eve...

Embodiment 3

[0060] A) Preparation of polymer emulsion

[0061] In the dispersion kettle, under 100-400r / min rotating speed stirring, add 60 parts by weight of acrylic acid emulsion, 10 parts by weight of water-based polyurethane and 5 parts by weight of disproportionated rosin, 3 parts by weight of propylene glycol and 22 parts by weight of water, and stir After 10 minutes, a polymer emulsion was obtained.

[0062] B) Preparation of filler slurry

[0063] In the high-speed dispersion kettle, add 20 parts by weight of hydroxyapatite, 1 part by weight of KH-550, 1 part by weight of CIT and 78 parts by weight of deionized water, and disperse and stir at 500-1000r / min for 30-60 minutes, then transfer it to a sand mill for grinding, and grind for 40-60 minutes at 2000-3000r / min until the fineness reaches below 30μm.

[0064] Add the prepared filler slurry into the polymer emulsion, the ratio of the polymer emulsion to the filler slurry is 10:10, and stir evenly to obtain the coating composit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com