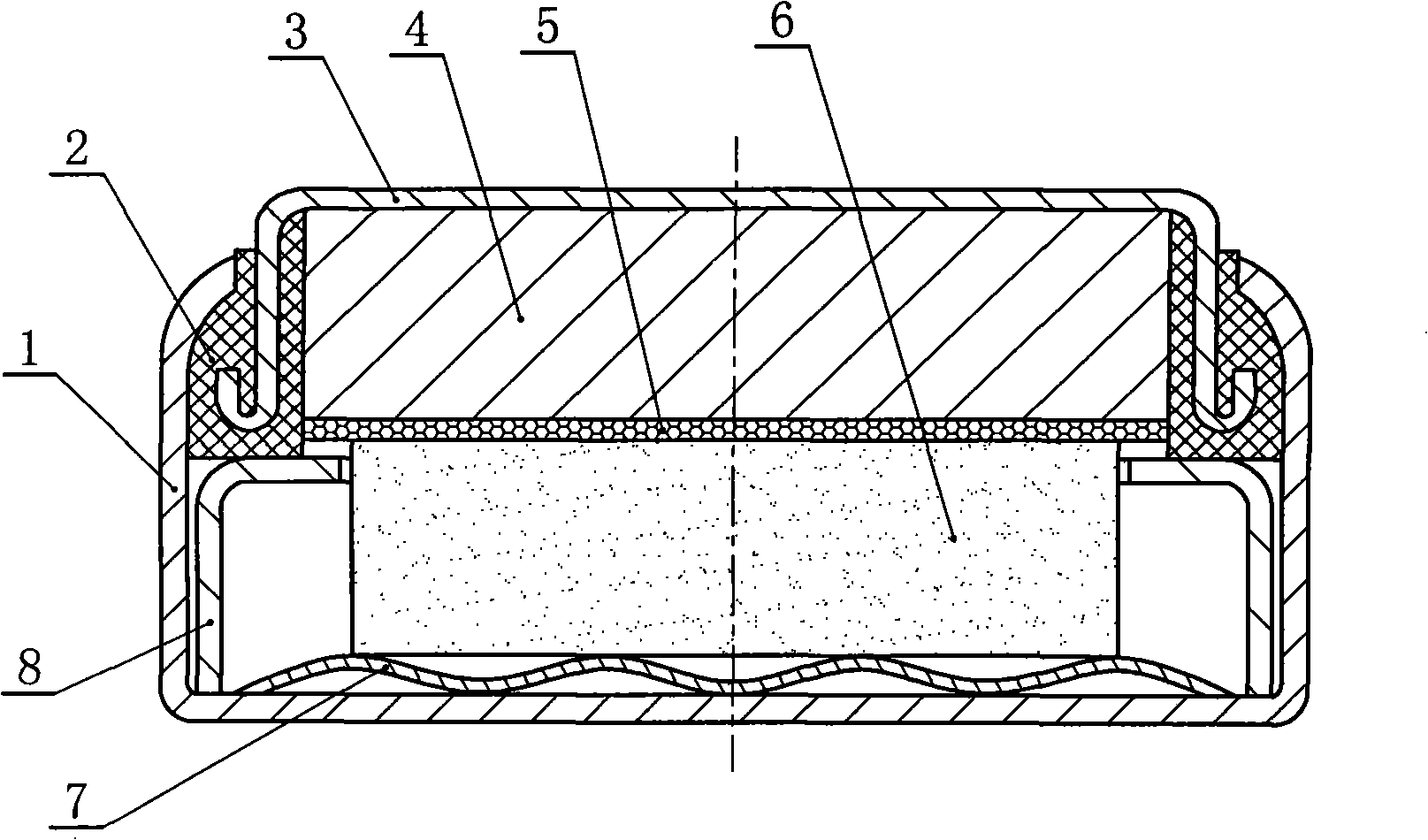

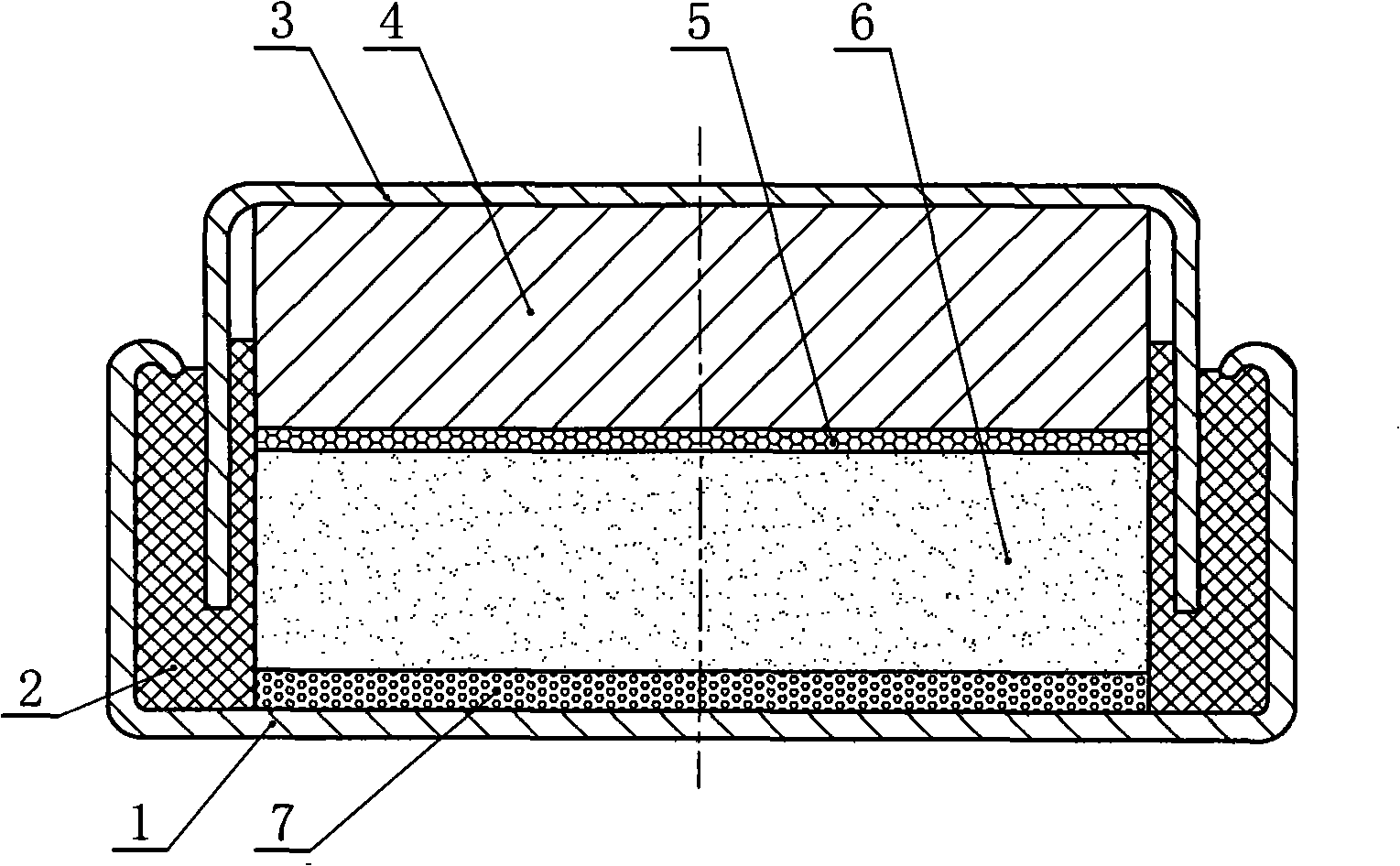

Bulge-prevention type buckle type lithium pyrite battery and manufacturing method thereof

An anti-expansion technology for iron disulfide batteries, applied in battery electrodes, battery pack components, non-aqueous electrolyte batteries, etc., can solve the problems of battery expansion and affecting battery performance, and achieve enhanced stability, overall quality, and The effect of expanding the range of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Mix 50g of iron disulfide powder and 50g of graphite powder evenly, then add 100g of polytetrafluoroethylene emulsion with a mass concentration of 5%, stir it with a glass rod to form a paste, press it into a sheet with a thickness of 1mm with a tablet machine, and press the tablet Put the body into a vacuum oven with a temperature of 150°C and a pressure of 1kPa, dry for 12 hours, take out the sheet, cut it into a round cake with a diameter of φ2.2mm, and then put the round cake into a vacuum oven with a temperature of 150°C and a pressure of 1kPa. Dry in an oven for 12 hours, then transfer the round cake to a dry environment with a relative humidity of ≤1%, and use it as a positive electrode. Put the negative electrode material with a diameter of φ2.2mm and a thickness of 0.5mm lithium cake into half a stainless steel shell, place a glass fiber diaphragm on it, then put the positive electrode on the diaphragm, and put a 1mm thick diameter φ2 on the positive electrode ...

Embodiment 2

[0031] Mix 80g of artificial iron disulfide powder and 20g of graphite powder evenly, then add 10g of acrylate aqueous solution with a mass concentration of 15%, stir it with a glass rod to form a paste, press it into a sheet with a thickness of 1mm with a tablet machine, and press the sheet Put it in a vacuum oven with a temperature of 150°C and a pressure of 1kPa, dry for 12 hours, take out the sheet, cut it into a round cake with a diameter of φ6.2mm, and then put the round cake in a vacuum oven with a temperature of 150°C and a pressure of 1kPa , and dried for 12 hours, the round cake was transferred to a dry environment with a relative humidity of ≤1%, and it was used as a positive electrode. Put the negative electrode material (Li: 98%wt, Al: 2%wt) of the lithium-aluminum alloy cake with a diameter of φ6.2mm and a thickness of 1.8mm into half a stainless steel shell, put a polypropylene (PP) film on it, and then Put the positive electrode on the diaphragm, put a 1.1mm th...

Embodiment 3

[0033] Mix 70g of natural iron disulfide powder and 30g of copper powder evenly, then add 100g of carboxymethyl cellulose with a mass concentration of 2%, stir it with a glass rod to form a slurry, and spread the slurry on a 20cm×10cm×2mm foamed titanium smear repeatedly with a horn spoon, so that the slurry is fully filled into the gap of the foamed titanium with a porosity of 95%, and then put the foamed titanium into a vacuum oven with a temperature of 150°C and a pressure of 1kPa, and bake Dry for 12 hours, take out the foamed titanium, press the foamed titanium into a sheet with a thickness of 2mm with a tablet machine, cut the sheet into a round cake with a diameter of φ8.2mm, and then put the round cake into a vacuum oven at a temperature of 150°C , and dried for 12 hours, the round cake was transferred to a dry environment with a relative humidity of ≤1%, and it was used as a positive electrode. Put the negative electrode material (Li: 98%wt, Al: 2%wt) of a lithium-alu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com