Biodegradable and absorbable polymer superfine fibre film with radioactive nuclide marker and preparation and use thereof

A biopolymer and radionuclide technology, applied in the field of polymer ultrafine fiber membrane and its preparation, can solve the problems of insufficient hydrogel strength and in vivo stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

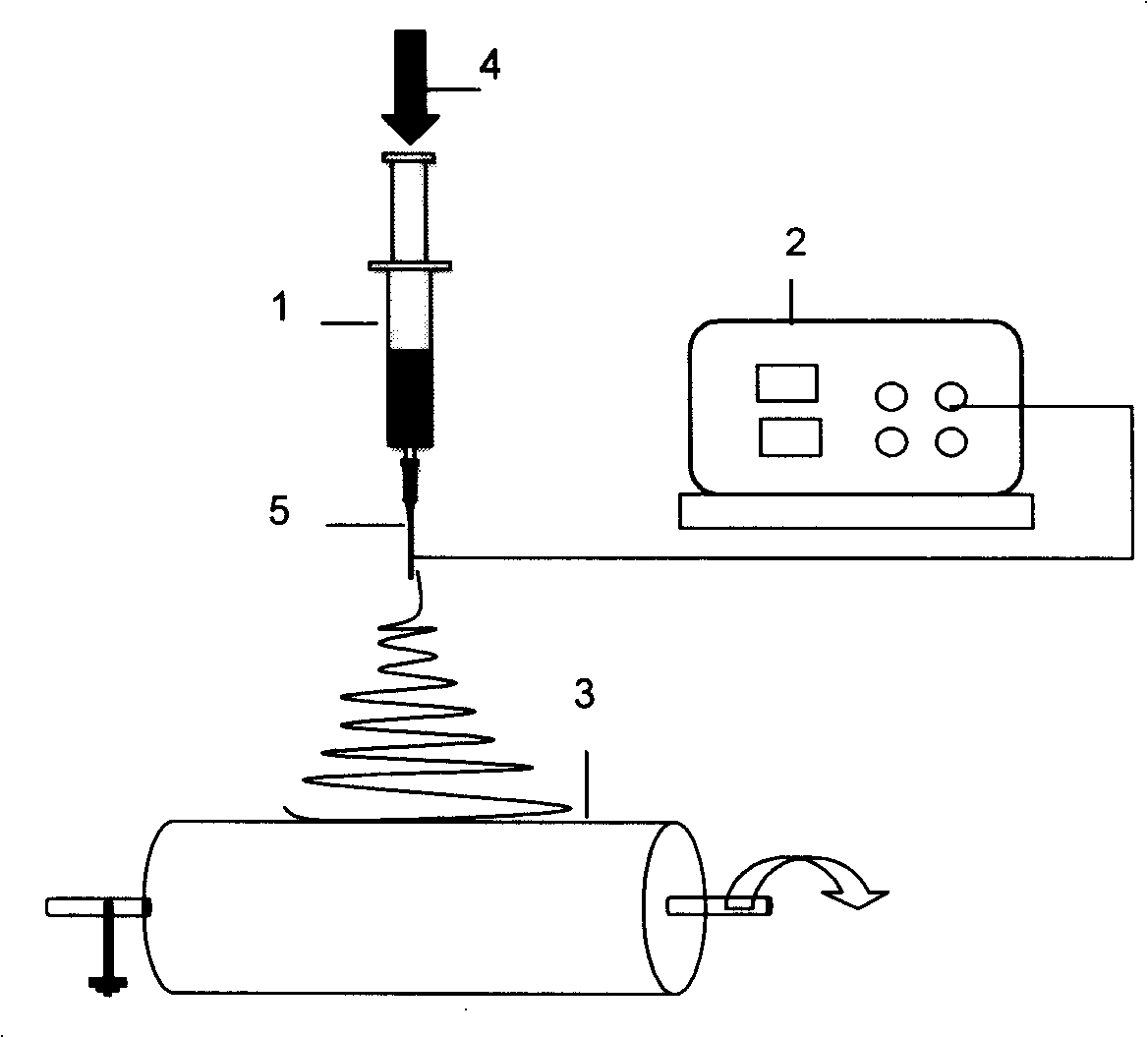

[0091] See figure 1 . The high-voltage power supply 2 adopts a negative DC high-voltage output power supply, and the maximum output voltage is 40kV. The high-voltage power supply is connected to the injection end of the spinneret 5 of the syringe 1 through wires; the output mode of the syringe pump 4 adopts output pumps with various output frequencies to drive the syringe. Feeding, the maximum output range is 300 microliters per minute, the syringe pump is connected to the feed end of the spinneret of the syringe 1 through a catheter; the material of the spinneret is stainless steel, and the diameter of the spinneret is 0.8mm; the collection device is a rotating drum, The diameter is 80mm; the electrospinning environment temperature control device adopts infrared lamp heating method, the system is controlled by PID (proportional integral and proportional differential controller), and the control accuracy is within ±3°C.

[0092] (1) Preparation of solution: preparation of PLA...

Embodiment 2

[0097] The equipment is the same as in Example 1.

[0098] (1) Preparation of solution: prepare PLGA (LA / GA=75 / 25, molecular weight 150,000) concentration is 10ml of DMF solution of 25w / w%, add radionuclide compound 177 LuCl 3 0.01ml of aqueous solution, 177 LuCl 3 Quality: The quality of PLA is 1:200,000, and the polymer solution is placed in the syringe;

[0099] (2) Adjust the electrospinning device: select a single spinneret device and a metal plate as a collector; adjust the distance between the spinneret and the collector to be 10cm; the ambient temperature of spinning is 40 degrees, and the air velocity in the environment Controlled at 0.5~0.8m 3 / hr;

[0100] (3) Set the spinning process parameters: turn on the high-voltage power supply, adjust the voltage to 22KV, and the feeding speed of the solution is 40ul / min to spin, and the collected PLGA ultrafine fiber membrane is repeatedly used with deionized water and absolute ethanol After rinsing, vacuum-dry in a va...

Embodiment 3

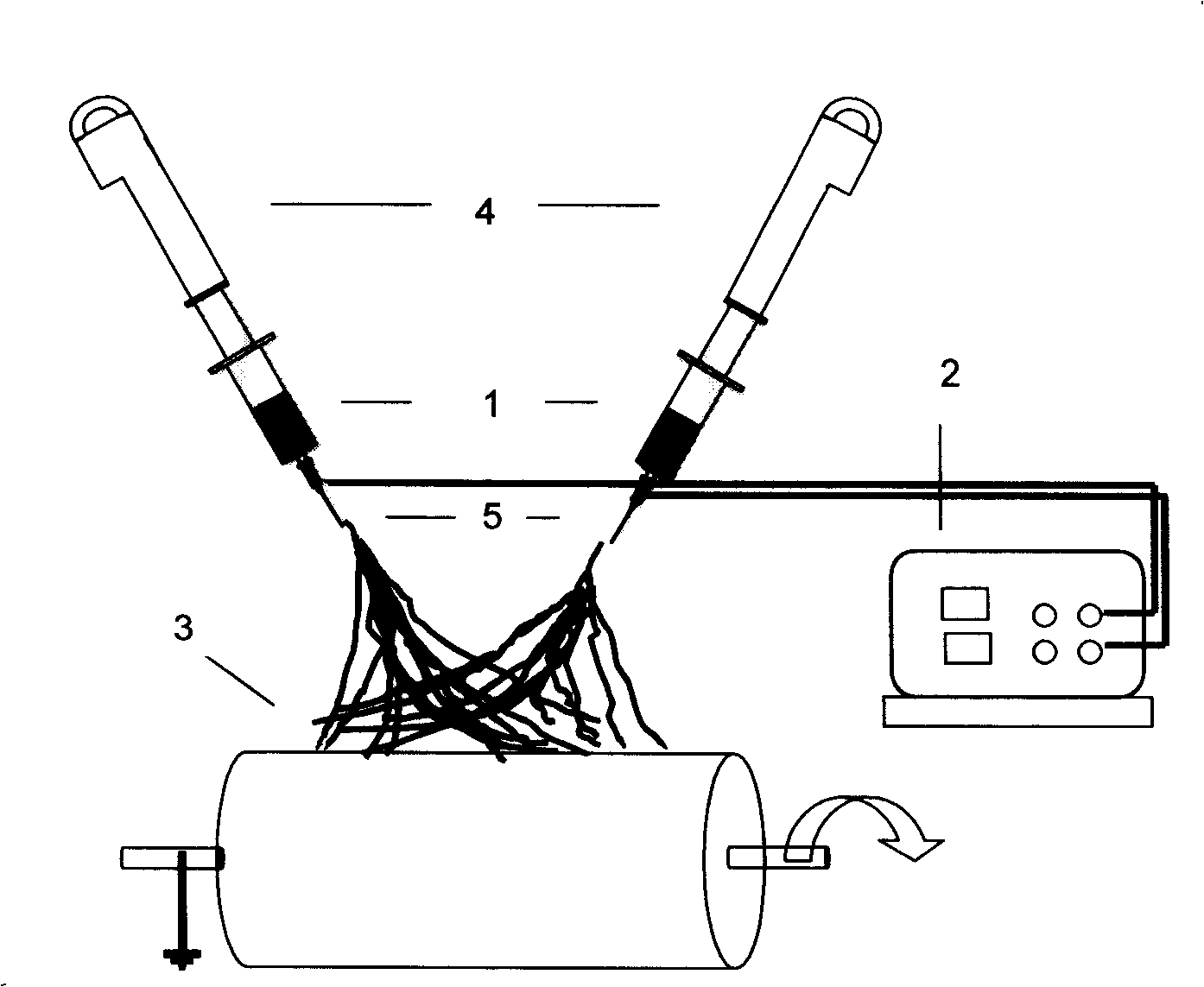

[0103] See figure 2 . The high-voltage power supply 2 adopts a negative DC high-voltage output power supply, and the maximum output voltage is 40kV. The high-voltage power supply is connected to the injection end of the spinneret 5 of the syringe 1 through wires; the output mode of the syringe pump 4 adopts output pumps with various output frequencies to drive the syringe. Feeding, the maximum output range is 300 microliters per minute, the syringe pump is connected to the feed end of the spinneret of syringe 1 through a catheter; the spinneret material is made of stainless steel, and the diameter of the spinneret is 0.8mm; the spinneret is 60 degrees The included angle, the distance between the spinnerets is 1-5cm; the collection device is a rotating drum 3 with copper wires arranged in parallel, with a diameter of 120mm, and the electrostatic spinning environment temperature control device adopts infrared lamp heating method, and the system is PID control with high control ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com