Polyurethane curing agent with low free MDI monomer and method for preparing same

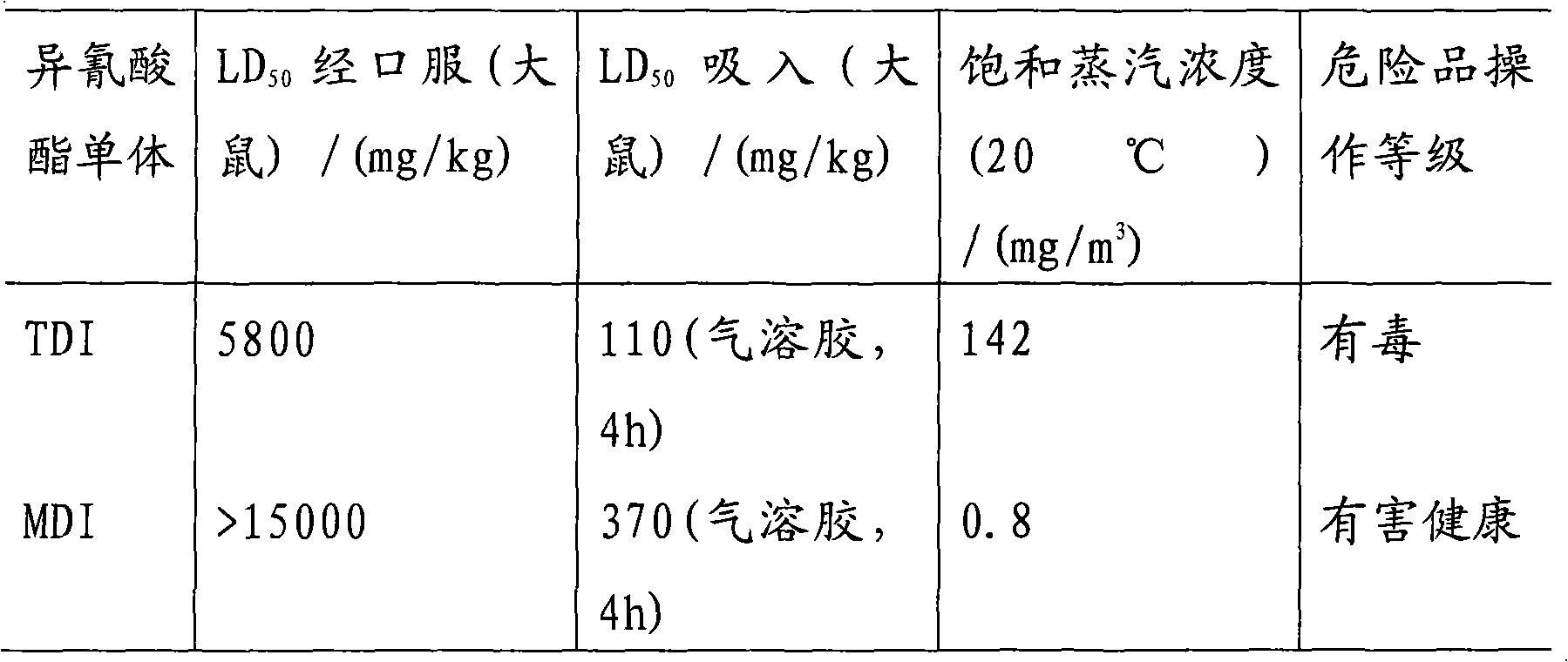

A polyurethane curing agent, low free technology, used in polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve problems such as health and safety hazards, increase humidity sensitivity, reduce product performance, etc., to achieve savings Low cost, equipment investment and operating cost, low toxicity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

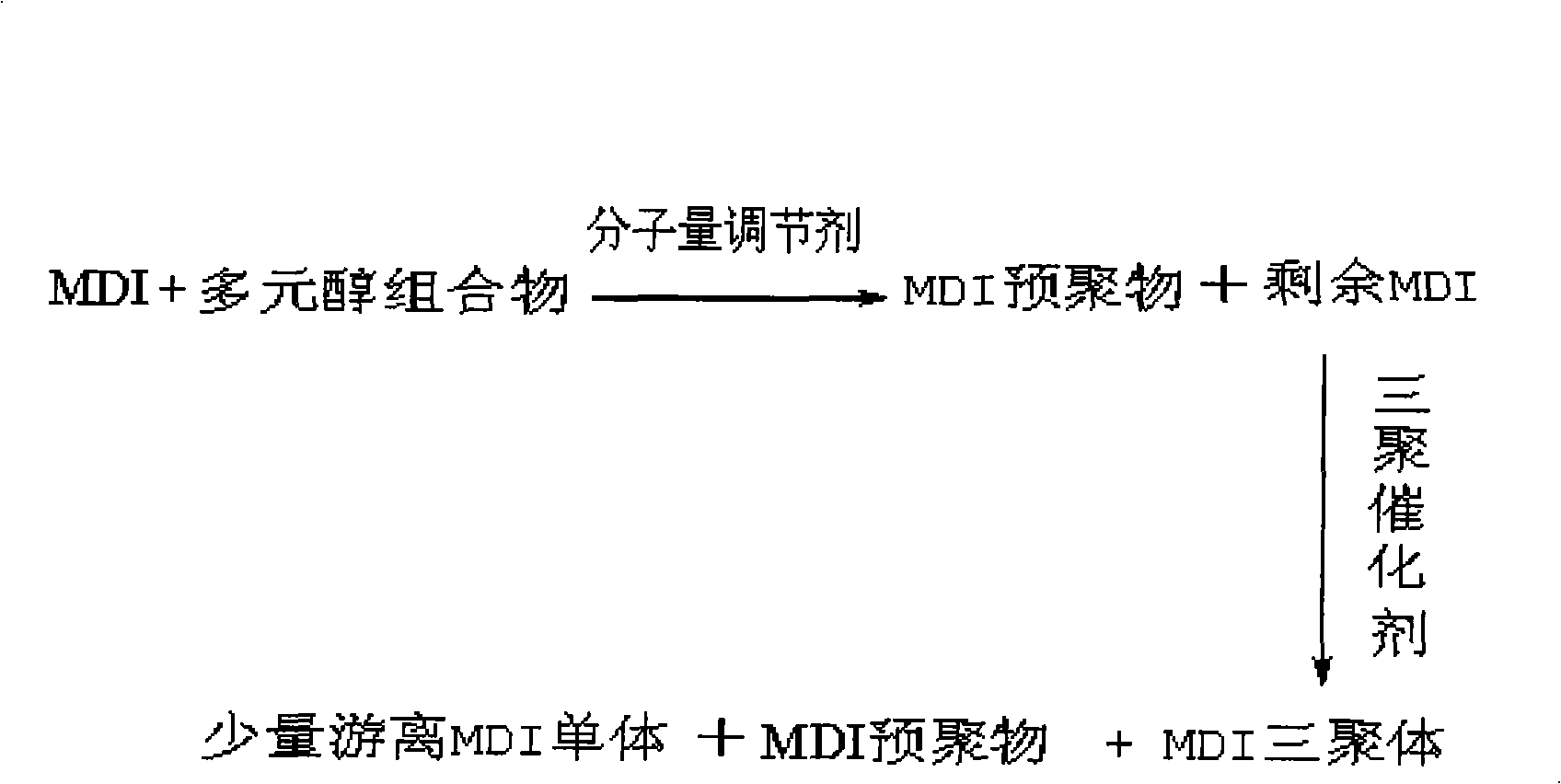

Method used

Image

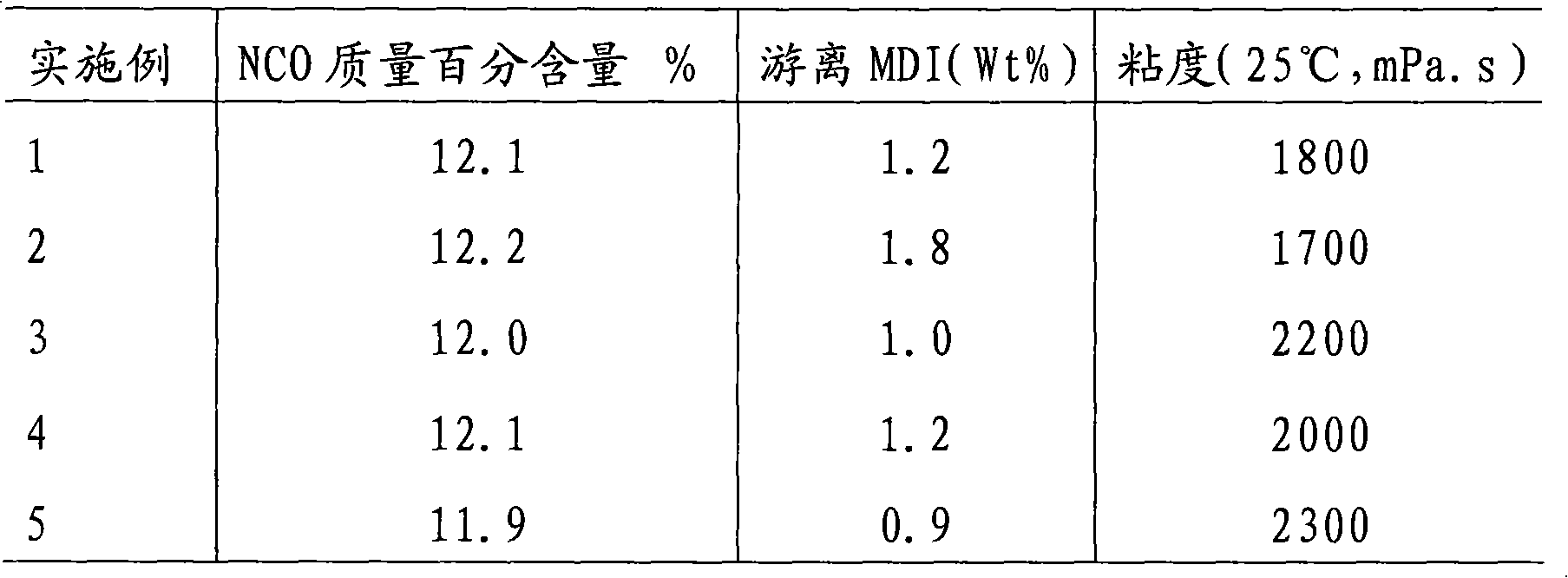

Examples

Embodiment 1

[0034] Add 188g of MDI-50 into a four-necked flask with a condenser and nitrogen protection, add 1.9g of molecular weight regulator diphenyldichlorosilane and 68.5g of ethyl acetate, start stirring, heat up to 50°C, and drop 49g Melting polyol composition (trimethylolpropane 4g, polyester diol 4g, polyester trihydric alcohol 80% solid content 41g), NCO: OH equivalent ratio is 4: 1, adds dropwise in about one hour, Keep warm at 70°C for about 2 hours, add 0.09g of triethylenediamine trimerization catalyst, keep warm at 90°C for reaction, when the total NCO content drops to 12%, cool down to 40°C, add 0.02g of benzoyl chloride inhibitor to terminate reaction.

Embodiment 2

[0036] Add 188g of MDI-100 into a four-necked flask with a condenser and nitrogen protection, add 2.8g of molecular weight modifier di-n-octyldichlorosilane and 69.5g of ethyl acetate, start stirring, heat up to 50°C, drop 51g of molten polyol composition (trimethylolpropane 5g, polyester diol 5g, polyester triol 80% solid content 41g), NCO: OH equivalent ratio is 3.5: 1, dropwise in about one hour , keep warm at 70°C for about 2 hours, add 0.24g of 2,4,6-tris(dimethylaminomethyl)phenol trimerization catalyst, keep warm at 70°C for reaction, when the total NCO content drops to about 12%, add 0.02 g benzoyl chloride inhibitor to terminate the reaction.

Embodiment 3

[0038] Add 188g of MDI-50 into a four-necked flask with a condenser and nitrogen protection, add 2g of molecular weight regulator ethylphenyl dichlorosilane and 68g of butyl acetate, start stirring, heat up to 50°C, and drop 50g Molten polyol composition (trimethylolpropane 5g, polyester triol 80% solid content 45g), NCO: OH equivalent ratio is 5: 1, add dropwise in about one hour, keep warm at 70°C for about 2 hours, Add 0.34g of N, N dimethylbenzylamine trimerization catalyst, keep warm at 80°C, and when the total NCO content drops to about 12%, drop the temperature and add 0.02g of benzoyl chloride polymerization inhibitor to terminate the reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com