Combined vacuum coating process of magnetron sputtering and multisphere ion plating

A technology of multi-arc ion plating and magnetron sputtering plating, which is applied in sputtering plating, ion implantation plating, vacuum evaporation plating, etc., can solve the problems of single process and achieve the goal of simplifying the process and eliminating environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

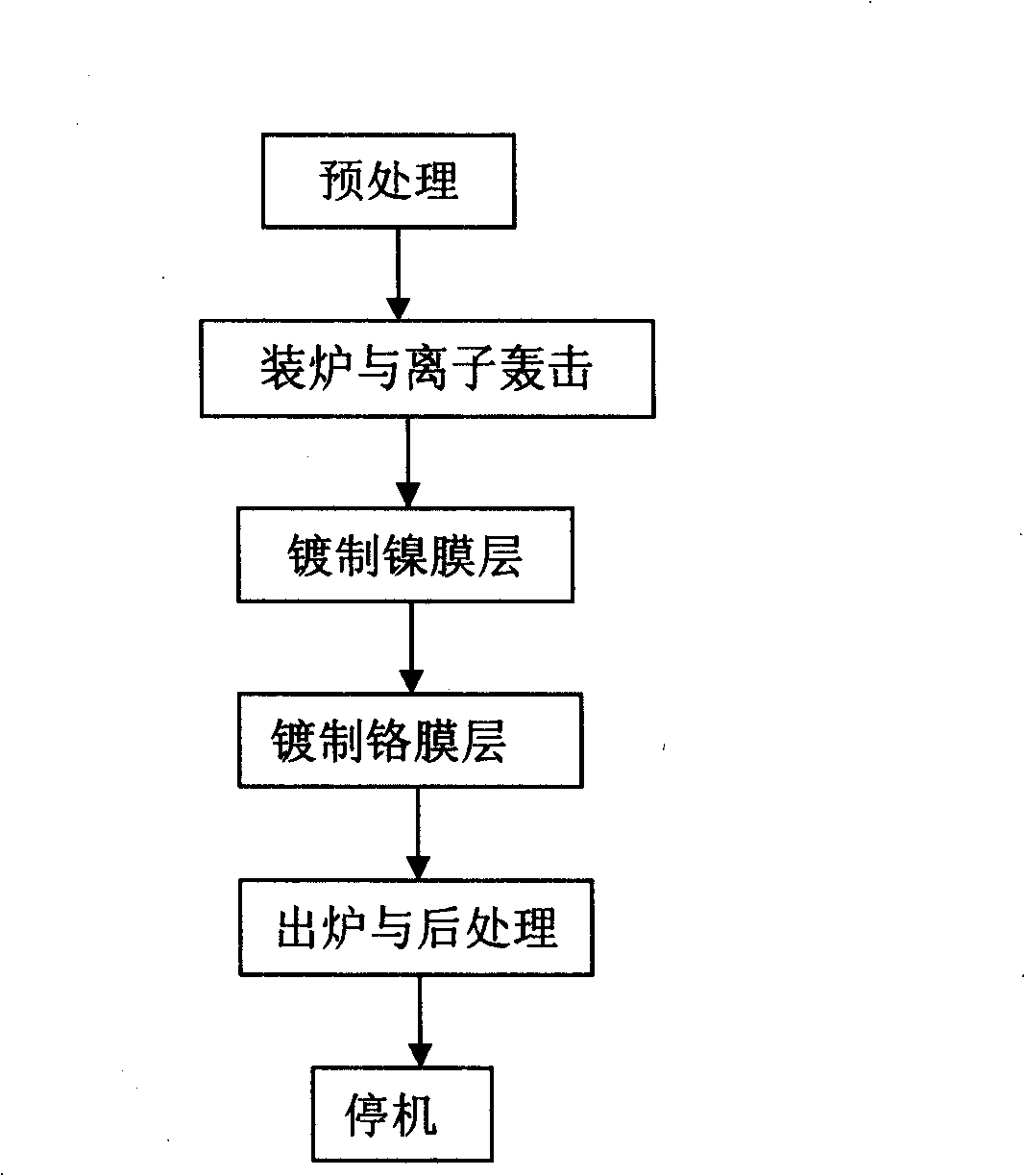

[0020] The method for plating nickel-chromium composite film on copper plumbing parts, the technological process is as follows figure 1 shown.

[0021] (1) Pretreatment: Clean the parts to be plated with clean water first, then ultrasonically clean them in acetone for 15 minutes to remove organic pollutants, then clean them with ultrasonic deionized water to remove residual acetone, and finally clean them with absolute ethanol and dry them;

[0022] (2) Furnace loading and ion bombardment: 1) Turn on the main power supply, cooling water, industrial computer and gas cylinder, turn on the mechanical pump for maintenance, and connect the power supply of the diffusion pump at the same time, preheat for 45 minutes; 2) Open the inflation valve in the vacuum system, After the vacuum chamber is deflated, open the vacuum chamber door; 3) Put the cleaned workpiece on the workpiece rack, then hang the workpiece rack on the workpiece rack turntable on the top of the vacuum chamber, and th...

Embodiment 2

[0028] The method for plating nickel-chromium composite film on copper plumbing parts, the technological process is as follows figure 1 shown.

[0029] (1) Pretreatment: Clean the parts to be plated with clean water first, then ultrasonically clean them in acetone for 15 minutes to remove organic pollutants, then clean them with ultrasonic deionized water to remove residual acetone, and finally clean them with absolute ethanol and dry them;

[0030] (2) Furnace loading and ion bombardment: 1) Turn on the main power supply, cooling water, industrial computer and gas cylinder, turn on the mechanical pump for maintenance, and connect the power supply of the diffusion pump at the same time, preheat for 60 minutes; 2) Open the inflation valve in the vacuum system, After the vacuum chamber is deflated, open the vacuum chamber door; 3) Put the cleaned workpiece on the workpiece rack, then hang the workpiece rack on the workpiece rack turntable on the top of the vacuum chamber, and th...

Embodiment 3

[0036] The method for plating nickel-chromium composite film on copper plumbing parts, the technological process is as follows figure 1 shown.

[0037] (1) Pretreatment: Clean the parts to be plated with clean water first, then ultrasonically clean them in acetone for 15 minutes to remove organic pollutants, then clean them with ultrasonic deionized water to remove residual acetone, and finally clean them with absolute ethanol and dry them;

[0038] (2) Furnace loading and ion bombardment: 1) Turn on the main power supply, cooling water, industrial computer and gas cylinder, turn on the mechanical pump for maintenance, and connect the power supply of the diffusion pump at the same time, preheat for 0.5min; 2) Open the inflation valve in the vacuum system, Open the vacuum chamber door after degassing the vacuum chamber; 3) Put the cleaned workpiece on the workpiece rack, then hang the workpiece rack on the workpiece rack turntable on the top of the vacuum chamber, and then clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com