Microbial immobilization method

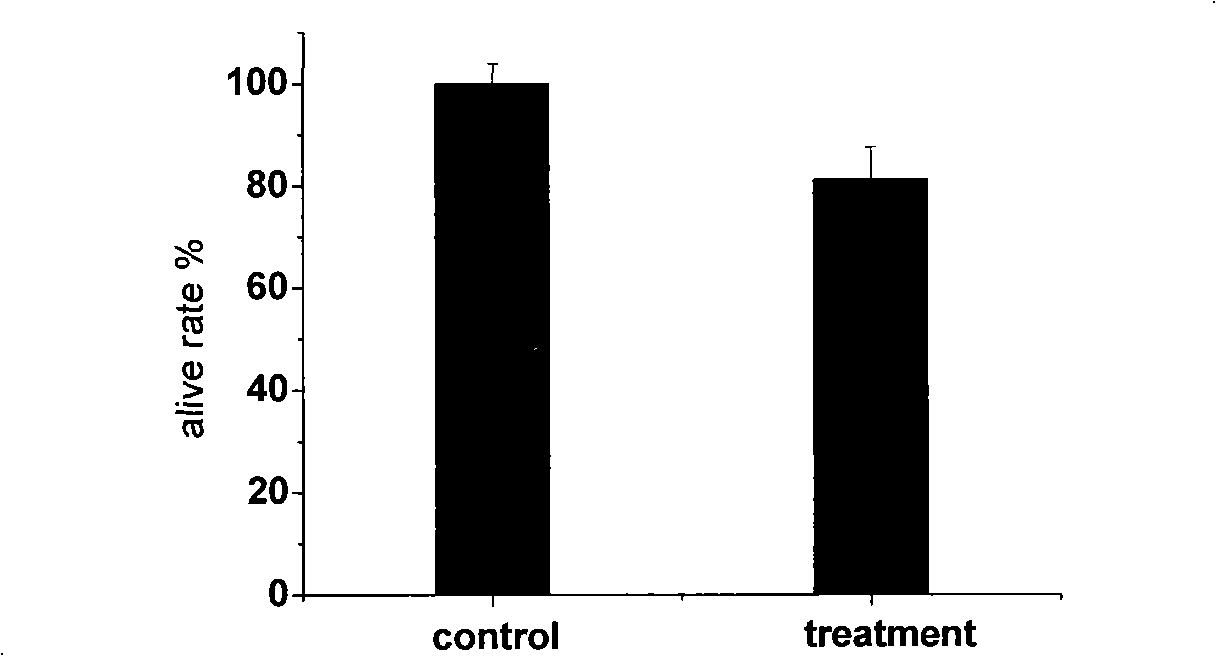

A technology for microorganisms and vegetable oils, applied in directions such as being fixed on/in an organic carrier, can solve the problems of difficulty in industrialization, inability to prepare calcium alginate gel beads, and small preparation scale, and achieve good microbial cell activity. , Not easy to leak, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1) At room temperature, a sodium alginate solution uniformly mixed with brewer's yeast and nano-scale calcium carbonate is added to the dispersion medium as a dispersed phase, and then stirred and emulsified at a stirrer speed of 150 rpm for 5 minutes to form an emulsion;

[0039] The weight-volume concentration of sodium alginate solution in the dispersed phase is 1.5%, and the weight-volume concentration of nanoscale calcium carbonate in the dispersed phase is 0.020%; the dispersed medium is liquid paraffin containing span85, and the volume ratio of the dispersed phase and the dispersed medium is 1:3;

[0040] The concentration of microbial seeds in the dispersed phase is 10 5 cfu / ml;

[0041] The volume percentage of span85 in the dispersion medium is 0.1%;

[0042] 2) Add liquid paraffin containing 5% glacial acetic acid to the above emulsion to adjust the pH of the emulsion to 6, and continue to stir for 5-10 minutes to form calcium alginate gel beads embedded wi...

Embodiment 2

[0053]Except that the volume ratio of the dispersed phase to the dispersion medium is 2:3, other conditions are the same as in the specific example 1.

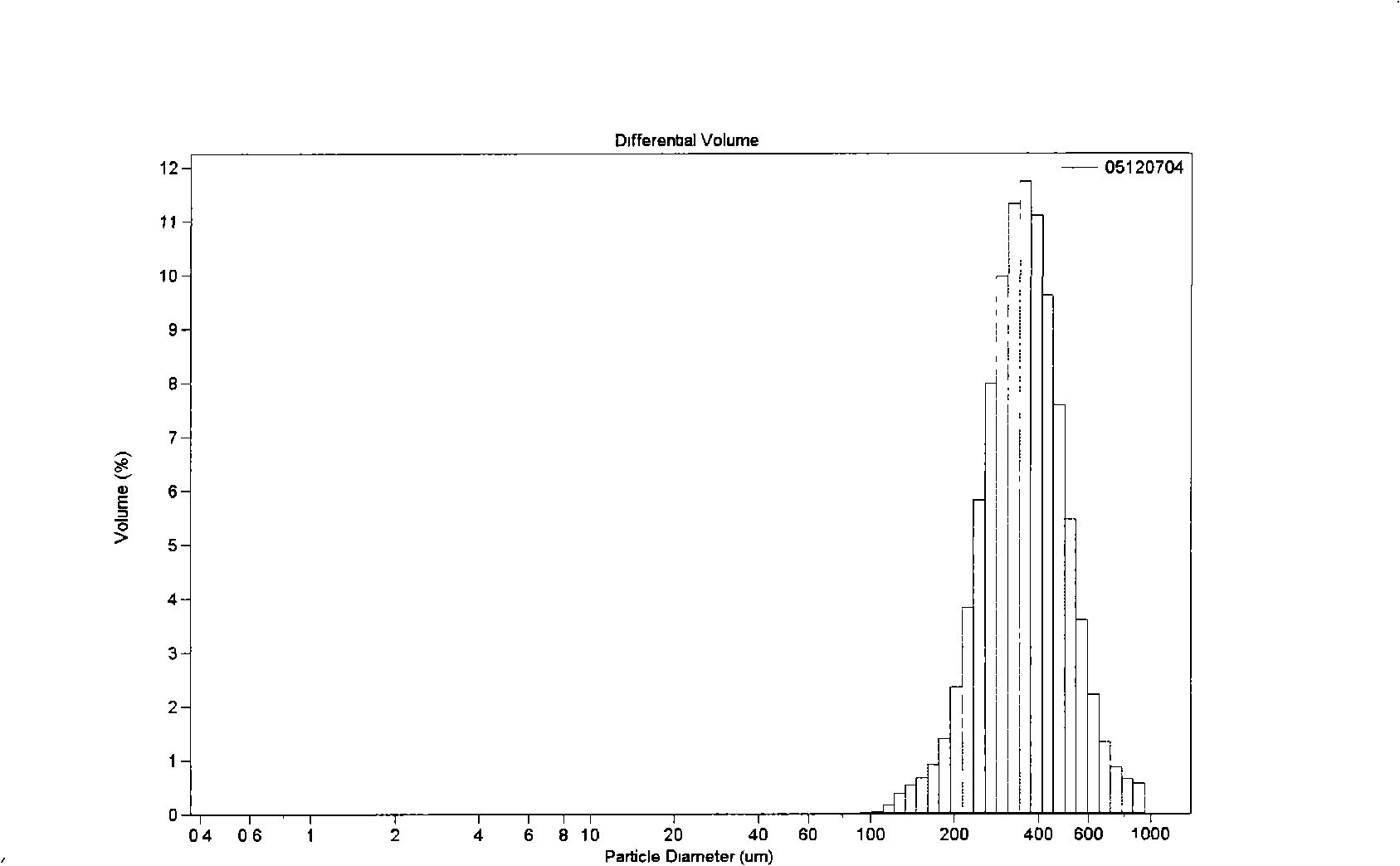

[0054] Under this condition, the average particle diameter of the microcapsules is 372 μm (see accompanying drawing 1, table 1).

Embodiment 3

[0056] 1) At room temperature, a sodium alginate solution uniformly mixed with lactic acid bacteria and nano-scale calcium carbonate is added to the dispersion medium as a dispersed phase, and then stirred and emulsified at a stirrer speed of 1000 rpm for 10 minutes to form an emulsion;

[0057] The weight-volume concentration of the sodium alginate solution in the dispersed phase is 2.0%, and the weight-volume concentration of nanoscale calcium carbonate in the dispersed phase is 0.010%; the dispersed medium is vegetable oil containing span85, and the volume ratio of the dispersed phase to the dispersed medium is 1 : 5;

[0058] The concentration of microbial seeds in the dispersed phase is 10 6 cfu / ml;

[0059] The volume percentage of span85 in the dispersion medium is 2%;

[0060] 2) Add vegetable oil containing 10% glacial acetic acid in the above emulsion to adjust the pH of the emulsion to 5, and continue to stir for 10 minutes to form calcium alginate gel beads embed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com