Lithium lanthanum titanium oxygen LLTO composite solid-state electrolyte material and synthesizing method thereof

一种固态电解质、电解质材料的技术,应用在锂离子电池用高安全性无机复合固态电解质材料及其制备领域,能够解决LLTO电导率低、晶界电导率低、达不到实用要求等问题,达到缩短实验周期、提高总电导率、节省能耗和生产成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

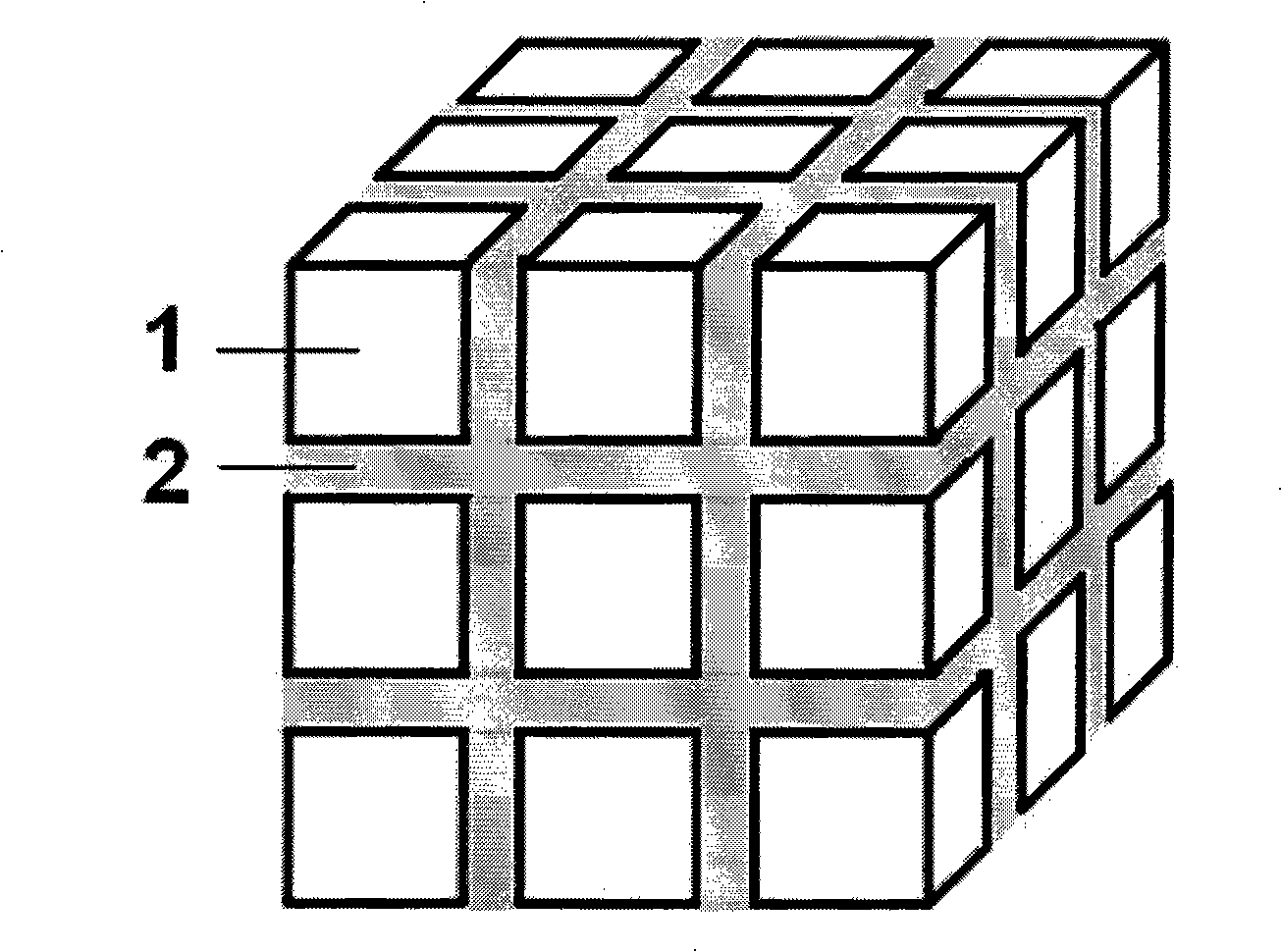

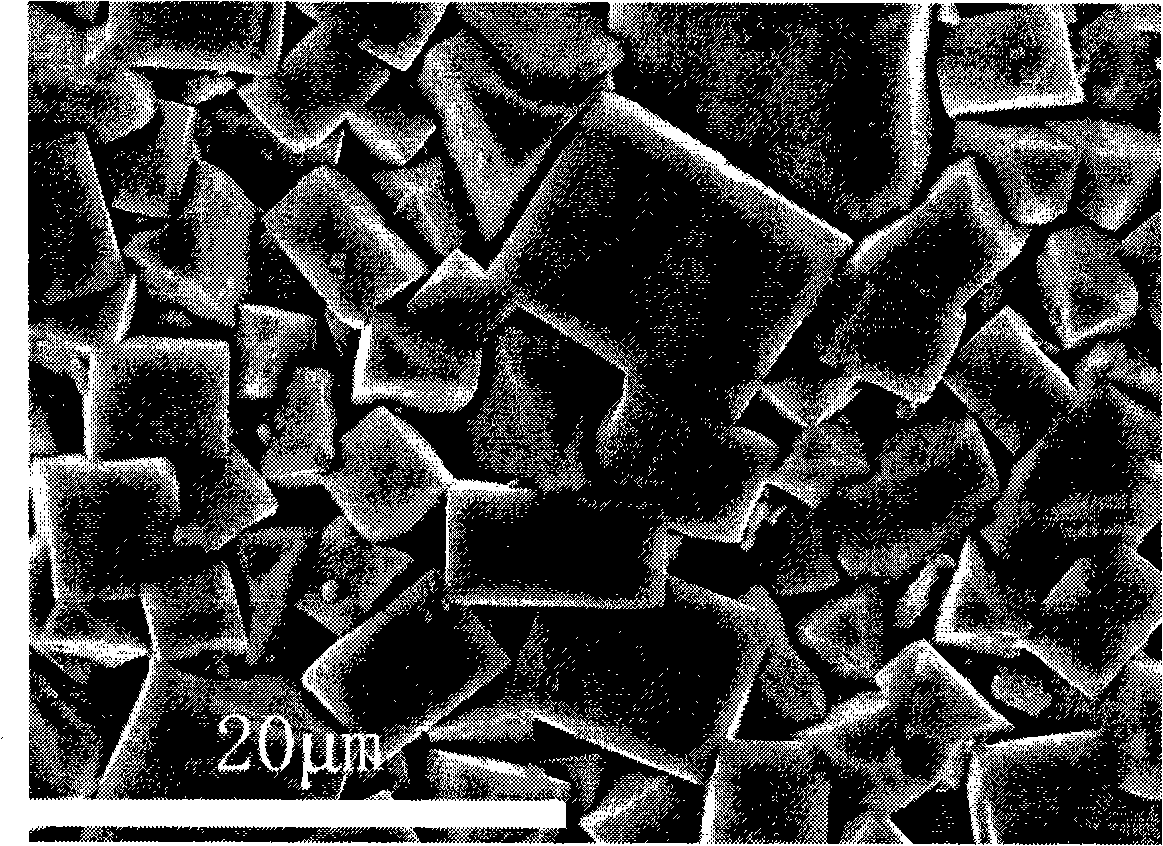

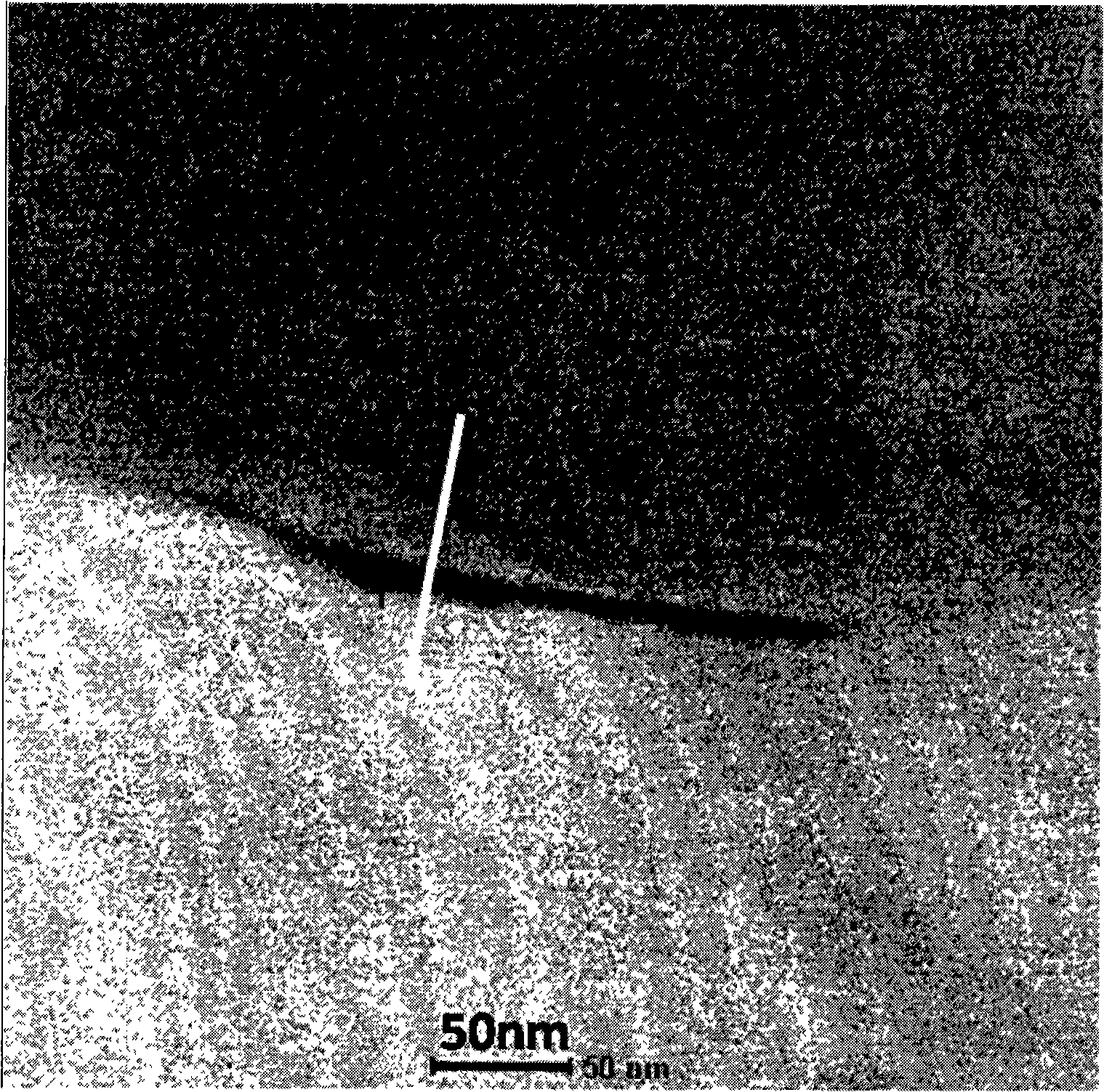

[0022] The present invention provides a novel lithium lanthanum titanium oxide composite solid electrolyte material containing an amorphous nano silicon oxide layer (2) at the grain boundary between crystal grains (1) and a synthesis method thereof. The experiment achieved the introduction of the amorphous nano-silicon oxide grain boundary layer (2) by using a wet chemical method. The wet chemical method used inexpensive organic silicide as an additive to be added to the lithium lanthanum titanium oxide solid electrolyte material. At 1-10%, the lithium lanthanum-titanium-oxygen composite solid electrolyte material containing silicon oxide grain boundary layer can be synthesized after sintering.

[0023] The process flow of the present invention is as follows:

[0024] (1) Preparation of LLTO raw material powder: use solid phase method or sol-gel method to prepare Li 3x La 2 / 3-x TiO 3 (x=0~0.16), disperse the raw material powder into ethanol to obtain a turbid liquid a for use;

[...

Embodiment 1

[0033] (1) Preparation of LLTO raw material powder: use solid phase method or sol-gel method to prepare Li 0.5 La 0.5 TiO 3 , Disperse 8 grams of raw material powder into ethanol to obtain turbid liquid a for use;

[0034] (2) Preparation of catalyst: prepare mixed solution b with 80ml water, 320ml ethanol and 800ml ammonia water;

[0035] (3) Preparation of silicon solution: Weigh 0.5 g of ethyl orthosilicate, and disperse it in ethanol to obtain solution c;

[0036] (4) Preparation of the mixed solution: After mixing the turbid solution a and the mixed solution b, drop the solution c into the mixed solution and stir evenly;

[0037] (5) Heating reaction: heating the mixed solution at 250°C for 3 hours;

[0038] (6) Drying: dry at 100°C to obtain composite powder;

[0039] (7) Sintering: After the composite powder is compressed, it is sintered at a high temperature of 1100 for 10 hours to obtain a composite solid electrolyte material.

Embodiment 2

[0041] (1) Preparation of LLTO raw material powder: use solid phase method or sol-gel method to prepare Li 0.5 La 0.5 TiO 3 , Disperse 2 grams of raw material powder into ethanol to obtain turbid liquid a for use;

[0042] (2) Preparation of catalyst: prepare mixed solution b with 80ml water, 240ml ethanol and 400ml ammonia water;

[0043] (3) Preparation of silicon solution: Weigh 0.125 g of ethyl orthosilicate, and disperse it in ethanol to obtain solution c;

[0044] (4) Preparation of the mixed solution: After mixing the turbid solution a and the mixed solution b, drop the solution c into the mixed solution and stir evenly;

[0045] (5) Heating reaction: heating the mixed solution at 200°C for 1 hour;

[0046] (6) Drying: dry at 90°C to obtain composite powder;

[0047] (7) Sintering: After the composite powder is pressed into tablets, it is sintered at a high temperature of 1200°C for 8 hours to obtain a composite solid electrolyte material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com