Functionalized carbon nano-tube used as solidifying agent of epoxy resin and preparation method

A technology of epoxy resin curing and carbon nanotubes, applied in the direction of dyeing low-molecular organic compound treatment, fibrous fillers, etc., to achieve functional design and application, and improve the effect of the interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

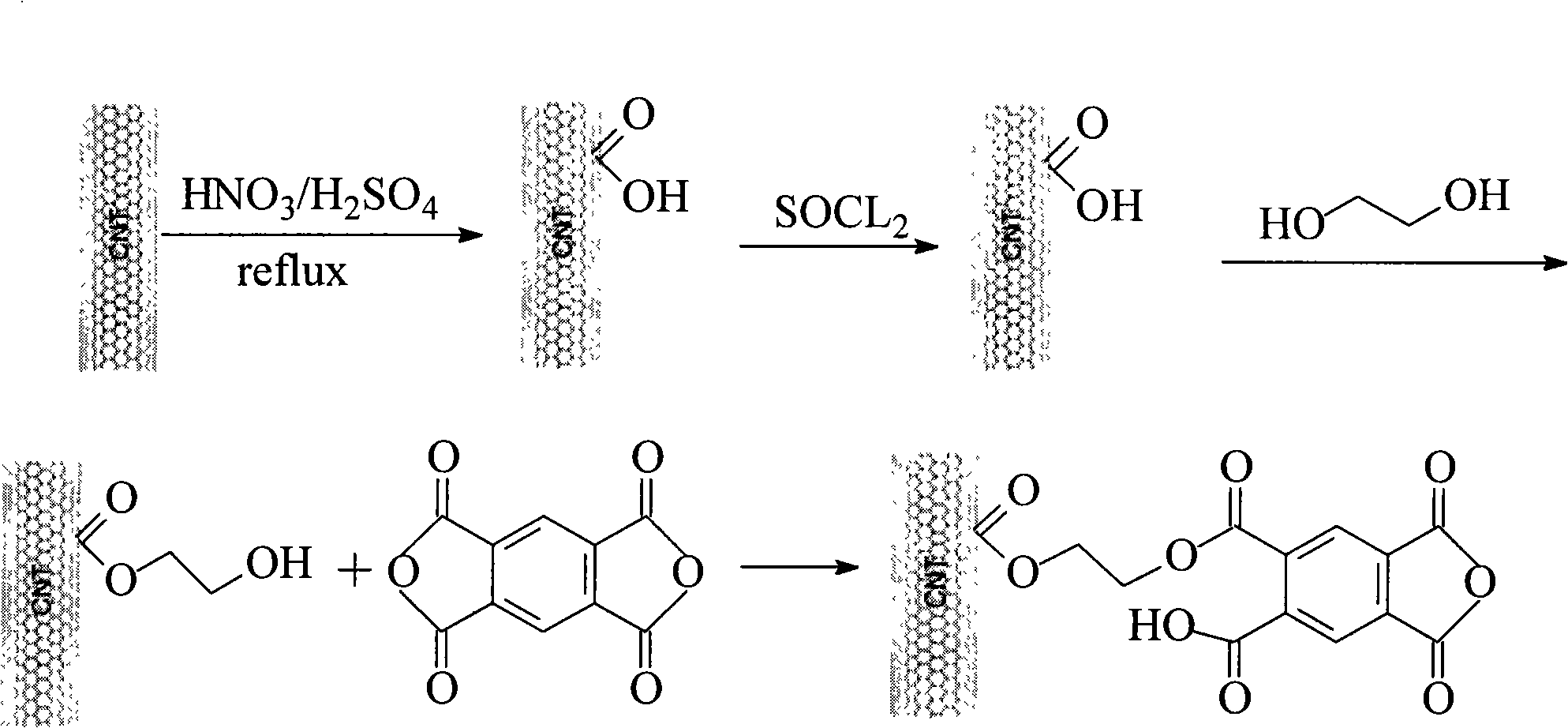

Embodiment 1

[0026] Step 1: mix 500mg multi-walled carbon nanotubes with 150ml H 2 SO 4 with HNO 3 mixed solution (98%H 2 SO 4 : 68% HNO 3 = 3:1) mixed, and reflux reaction for 4 hours at 35-40° C. and ultrasonic vibration. Then filter with a metafluoride membrane with a pore size of 0.45 μm, and wash with water until the pH is neutral. The product was placed in a vacuum oven and dried under vacuum at 40°C for 24h. Place the product after the above acidification and washing in H 2 SO 4 with H 2 o 2 mixed solution (98%H 2 SO 4 : 30%H 2 o 2 =4:1) at 70°C for 2h. Then filter with a metafluoride membrane with a pore size of 0.45 μm, and wash with water until the pH is neutral. The product was placed in a vacuum oven and dried under vacuum at 40°C for 24h.

[0027] Step 2: Take 400 mg of the above-mentioned acidified carbon nanotubes and place them in a reaction flask, add 20 ml of SOCl 2 and 1ml of N,N-dimethylformamide (DMF), stirred and refluxed at 70°C for 24h. Filter and ...

Embodiment 2

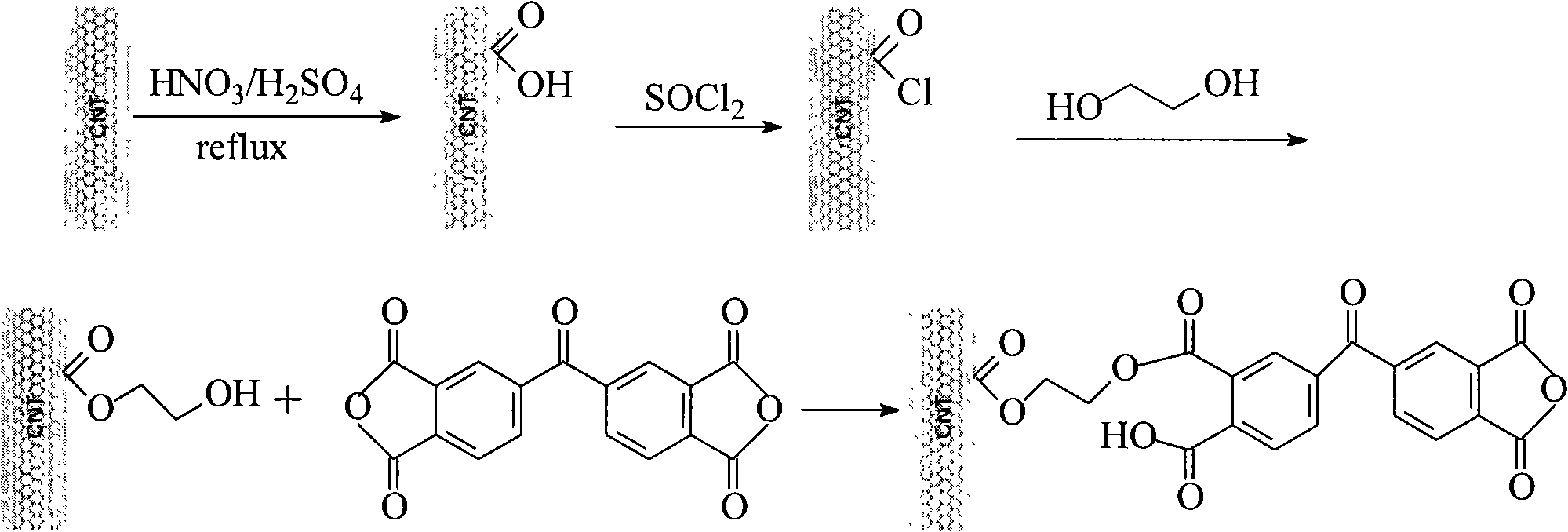

[0031] According to the method described in Example 1, 400 mg of hydroxylated carbon nanotubes was dissolved in dimethyl sulfoxide, ultrasonically oscillated for 30 minutes, 5 g of benzophenone tetracarboxylic anhydride was added, and 1 g of catalyst 4,4-dithiol was added, stirred evenly, and heated at 90 ° C. Under nitrogen protection, magnetic stirring, condensing and reflux, and a reaction time of 48 hours, a carbon nanotube epoxy resin curing agent containing acid anhydride groups and carboxyl groups on the surface was prepared. The schematic diagram of the reaction route is as figure 2 shown.

Embodiment 3

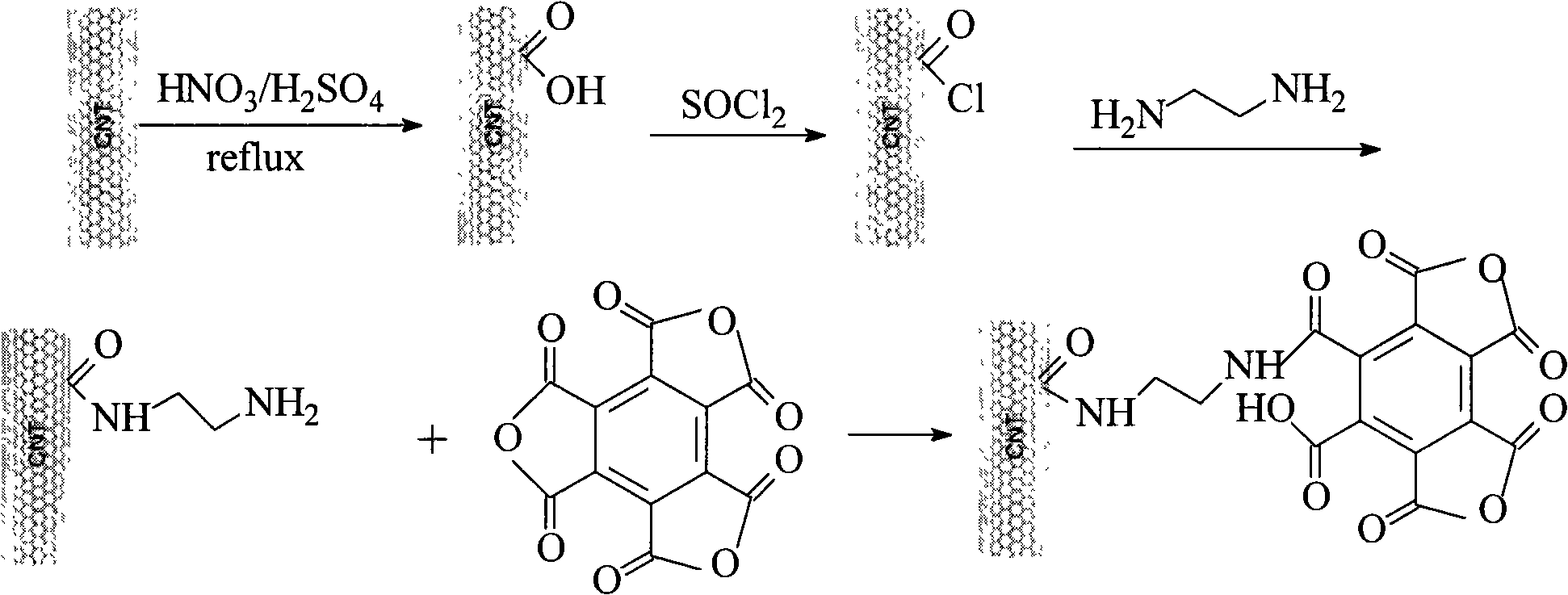

[0033] Acyl chloride carbon nanotubes were prepared according to the method described in Example 1. Take 400mg of acid chloride and place it in a 50ml single-necked bottle, add 30ml of ethylenediamine and 5ml of 3,3-dichlorobenzidine hydrochloride (DCB), heat to 120°C, condense and reflux for 48h with magnetic stirring. Then filter with a vinylidene fluoride membrane with a pore size of 0.45 μm, rinse with anhydrous THF for 5 times, put the product in a vacuum oven, and dry it at 40° C. for 24 hours to obtain a product of surface aminated carbon nanotubes.

[0034] Dissolve 400 mg of aminated carbon nanotubes in dimethyl sulfoxide, oscillate ultrasonically for 30 minutes, add 4 g of mellitic acid trianhydride, add catalyst nickel dibutyldithiocarbamate 1 g, stir evenly, at 90 ° C, under nitrogen protection , magnetically stirred, condensed and refluxed, the reaction time was 48h, and a carbon nanotube epoxy resin curing agent containing acid anhydride groups and carboxyl group...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com